Bill of Materials Software

Controlata is a comprehensive solution for managing bills of materials and calculating manufacturing costs. Our platform is designed for manufacturers across various industries who aim to standardize their processes, optimize material usage, and maintain precise control over production costs.

Complete Bill of Materials Management

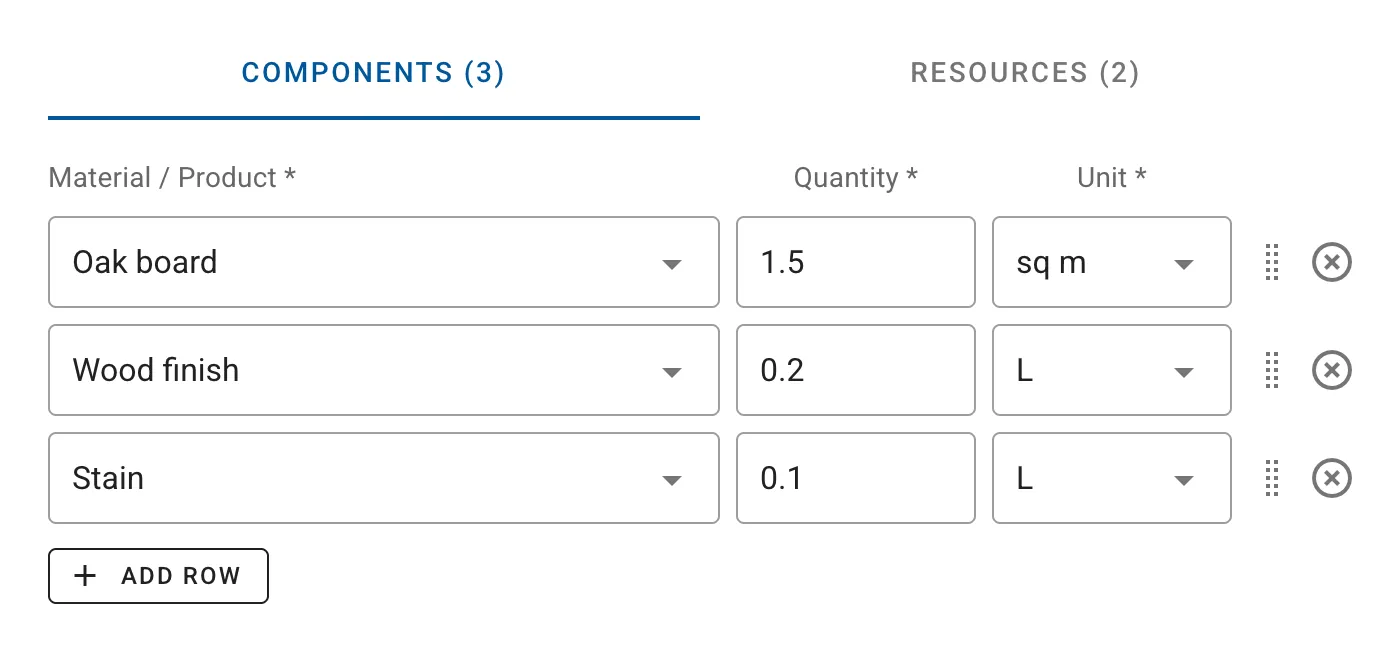

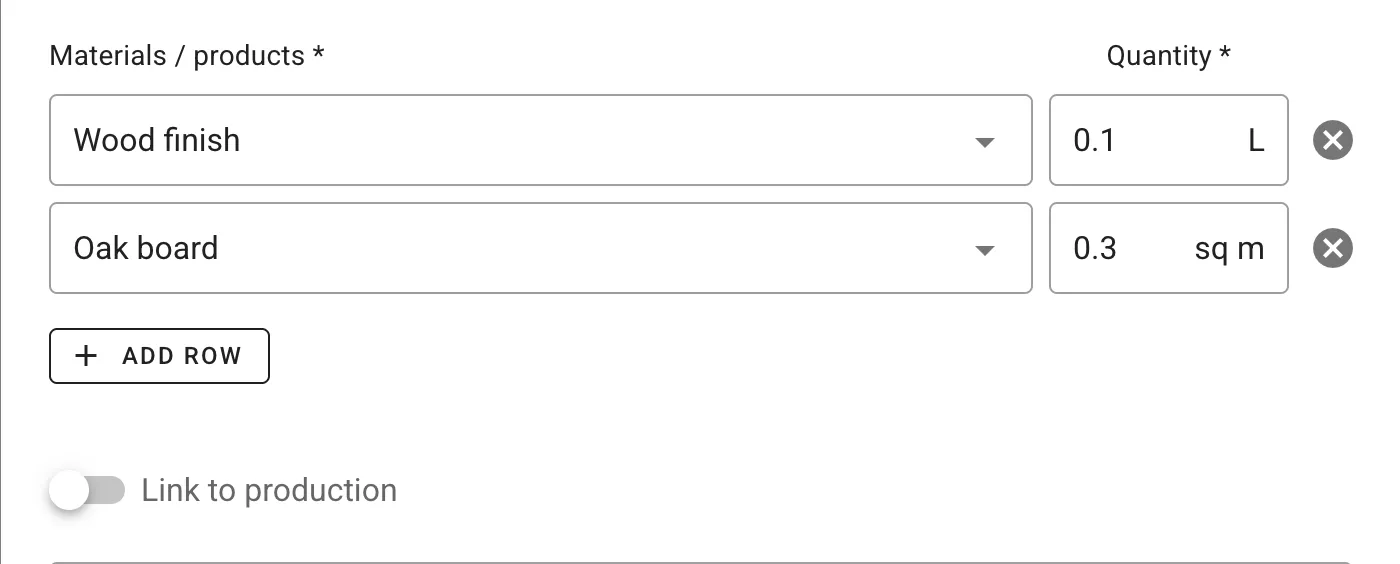

Simple BOM Creation

Create and customize your bills of materials effortlessly with Controlata. Define raw material requirements, set production specifications, and manage manufacturing parameters all in one intuitive system.

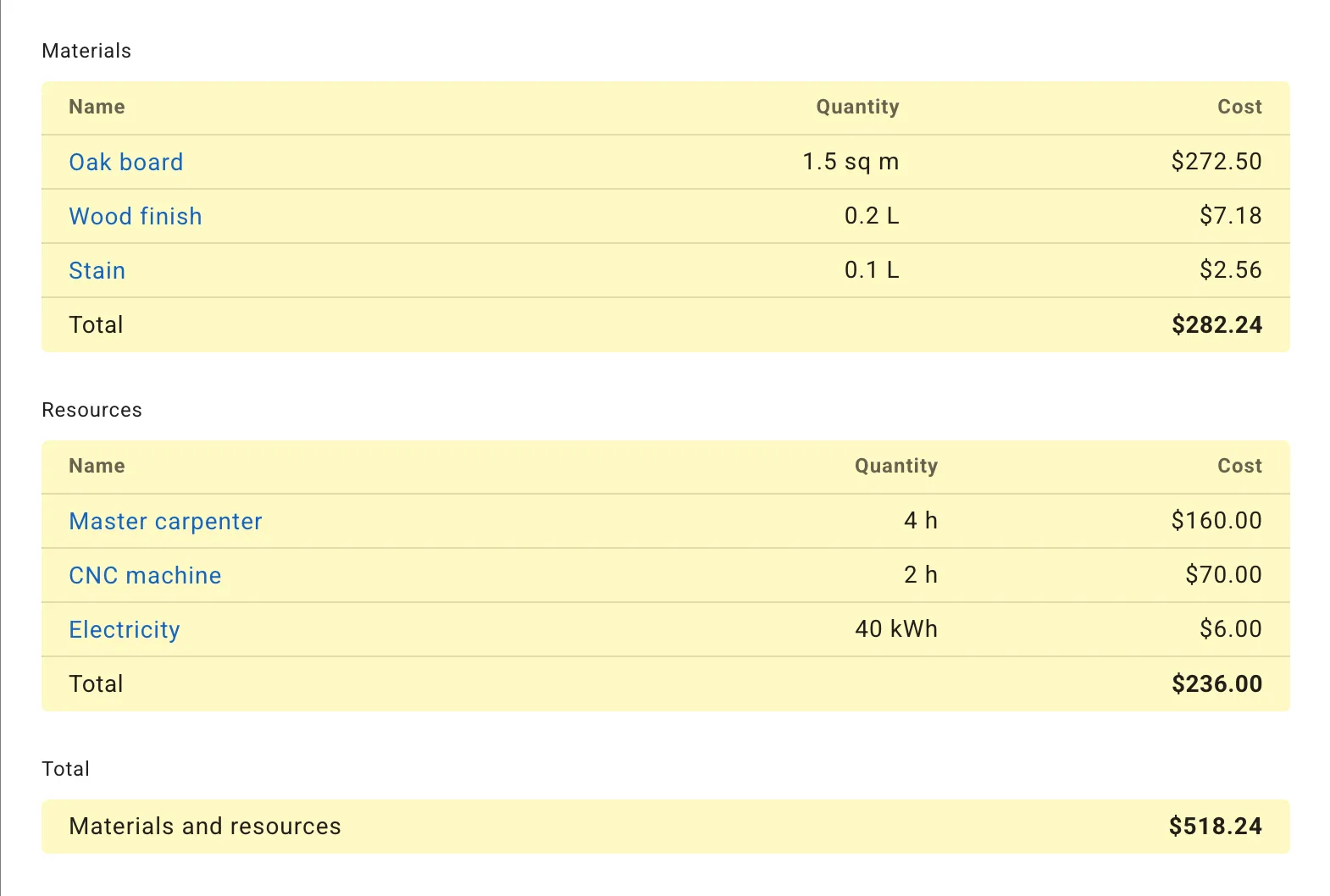

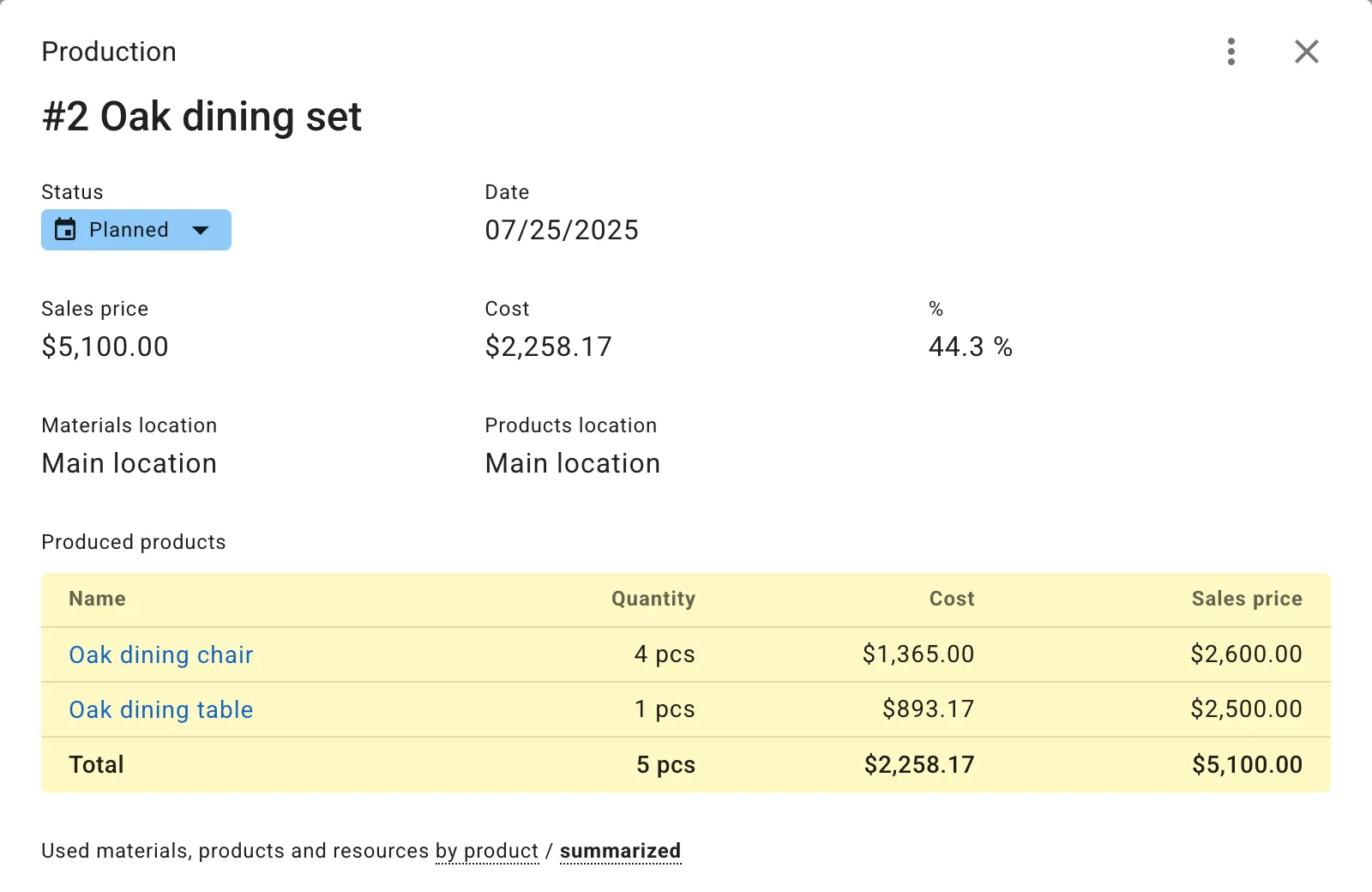

Automated COGS Calculation

As you build your bill of materials, Controlata instantly calculates unit costs by analyzing material requirements and current raw material prices. This provides real-time visibility into your production costs and helps forecast product margins.

Manufacturing Cost Tracking

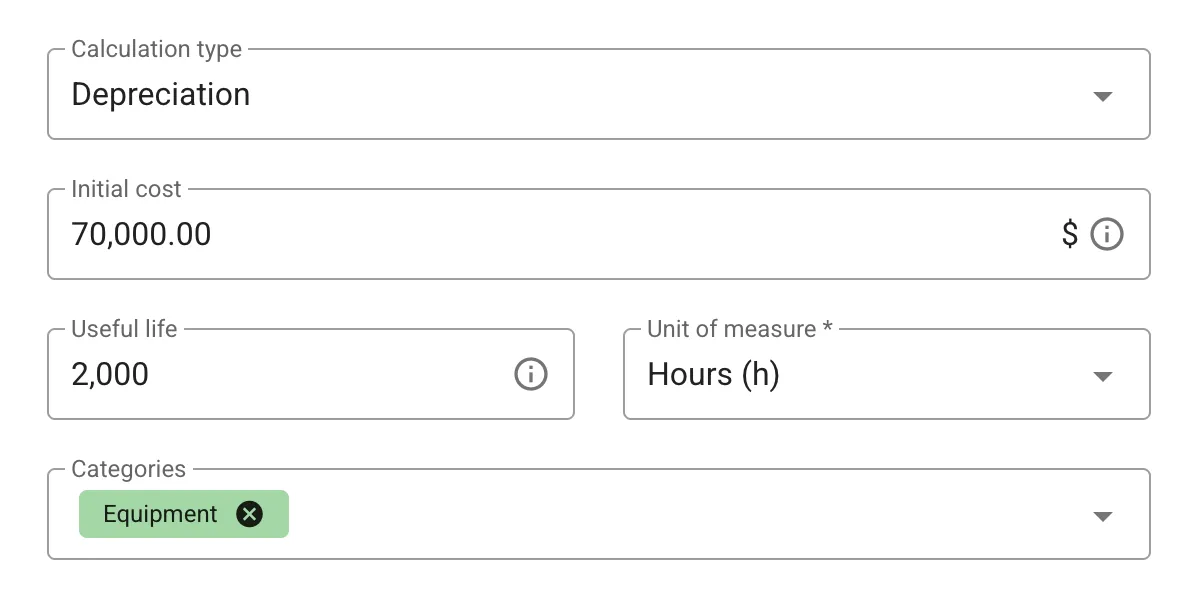

Calculate the true cost of your products by including all manufacturing expenses in your bill of materials:

- Direct labor costs

- Machine and equipment costs

- Utility expenses

- Production overhead

Get precise insights into your total manufacturing costs with automated calculations that factor in every resource used in production.

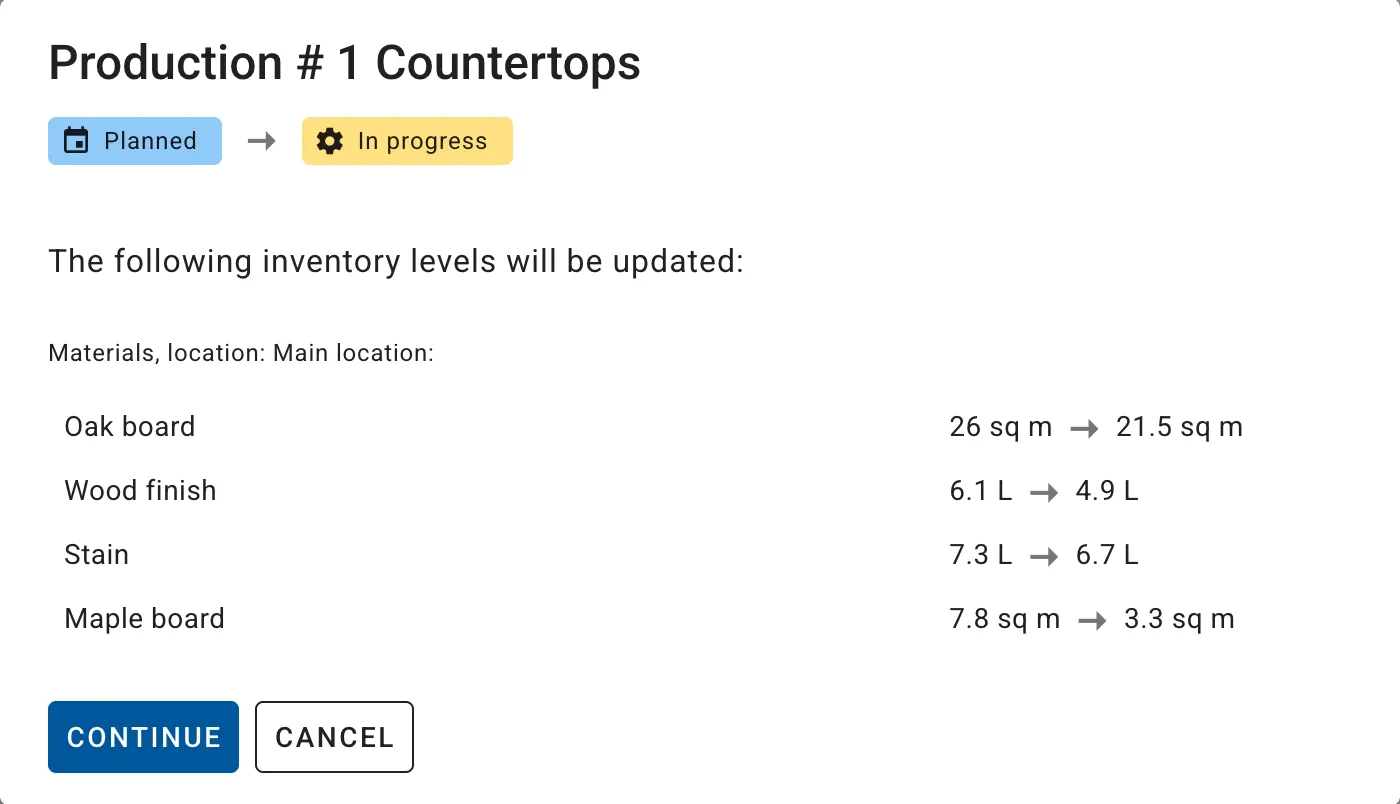

Automatic Material Tracking with BOMs

When production is completed, Controlata automatically updates your real-time inventory levels based on your bill of materials specifications. This streamlines your workflow by eliminating manual stock adjustments and ensures precise material consumption tracking according to your defined requirements.

Real-time Cost Updates

Track accurate production costs with FIFO-based calculations for your manufacturing operations. Get true material costs automatically updated as you allocate raw materials to production.

Raw Material Tracking

Monitor material consumption with automatic stock deductions based on your bill of materials during production. Easily adjust inventory levels for special cases like defects or material loss to maintain accurate stock records.

Optimize Manufacturing with Advanced BOM Tools

By implementing Controlata for bill of materials development and cost calculation, you can:

Easy BOM Management

Create and modify bills of materials without complexity. Update material requirements, production steps, and other specifications through a straightforward interface designed for all skill levels.

Standardize Manufacturing Operations

Ensure consistent manufacturing processes with detailed bills of materials. Keep your entire production team aligned with precise material requirements and step-by-step operation guidelines.

Accurate Product Costing

Get real-time visibility into planned and actual costs for each product. Automated calculations in your bill of materials instantly reflect current material prices for precise cost tracking.

Complete Cost Tracking

Factor in all production expenses in your bill of materials - from raw materials and labor to equipment costs and overhead. Get a true picture of your manufacturing costs.

Control Material Usage

Keep your material consumption aligned with established standards in your bill of materials. Spot any deviations instantly to prevent excess use and maintain efficient production.

Maximize Profitability

Analyze product margins with accurate cost data to make informed decisions. Identify opportunities to reduce production costs or adjust pricing for optimal profitability.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.