Why Industry-Specific Inventory Software Matters

Small businesses lose an average of 8% of their annual revenue to inventory mismanagement. Yet most software comparison articles treat all industries the same.

Here’s the reality: A manufacturing company’s inventory needs are fundamentally different from a restaurant’s or retail store’s. Manufacturing requires Bill of Materials tracking and production scheduling. Retail needs omnichannel synchronization and seasonal planning. Restaurants must manage perishables with FIFO rotation and recipe costing.

What This Guide Delivers

This analysis examines nine industry-leading solutions across three critical sectors. Unlike generic software roundups, we evaluate each tool against industry-specific criteria including:

- Implementation complexity and deployment timelines

- Integration ecosystem compatibility

- Scalability for 3-5 year growth planning

- Total cost of ownership with hidden costs

- Industry-specific compliance capabilities

Each recommendation includes real implementation data, ROI timelines, and specific use cases where solutions excel—or fall short.

Manufacturing Inventory Software: MRP and Beyond

Manufacturing inventory management extends far beyond simple stock counting. Manufacturers using proper MRP systems see an average 23% efficiency gain within 18 months of implementation.

Critical Manufacturing Requirements

Bill of Materials (BOM) Complexity: Manufacturing requires multi-level BOM tracking where a single finished product contains dozens of components, sub-assemblies, and raw materials. Each level needs cost rollup calculations and availability checking.

Work-in-Progress (WIP) Tracking: Unlike retail, manufacturing must track inventory through production stages—raw materials become WIP, then finished goods. This requires real-time cost accumulation using methods like FIFO (First-In-First-Out) for accurate profitability analysis.

Production Scheduling Integration: Inventory availability must sync with production capacity planning. A missing $2 component can halt production of a $2,000 assembly.

Top 3 Manufacturing Solutions

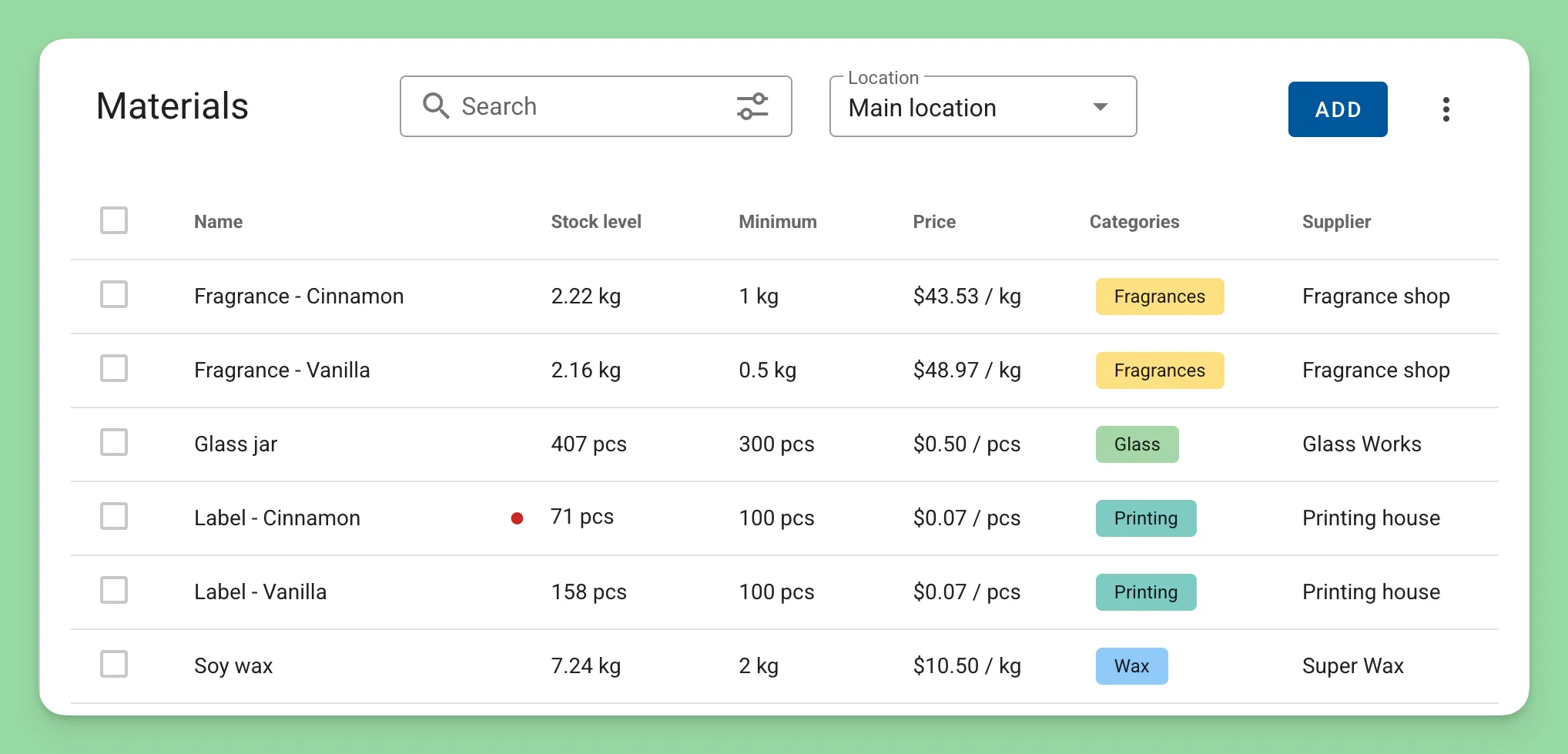

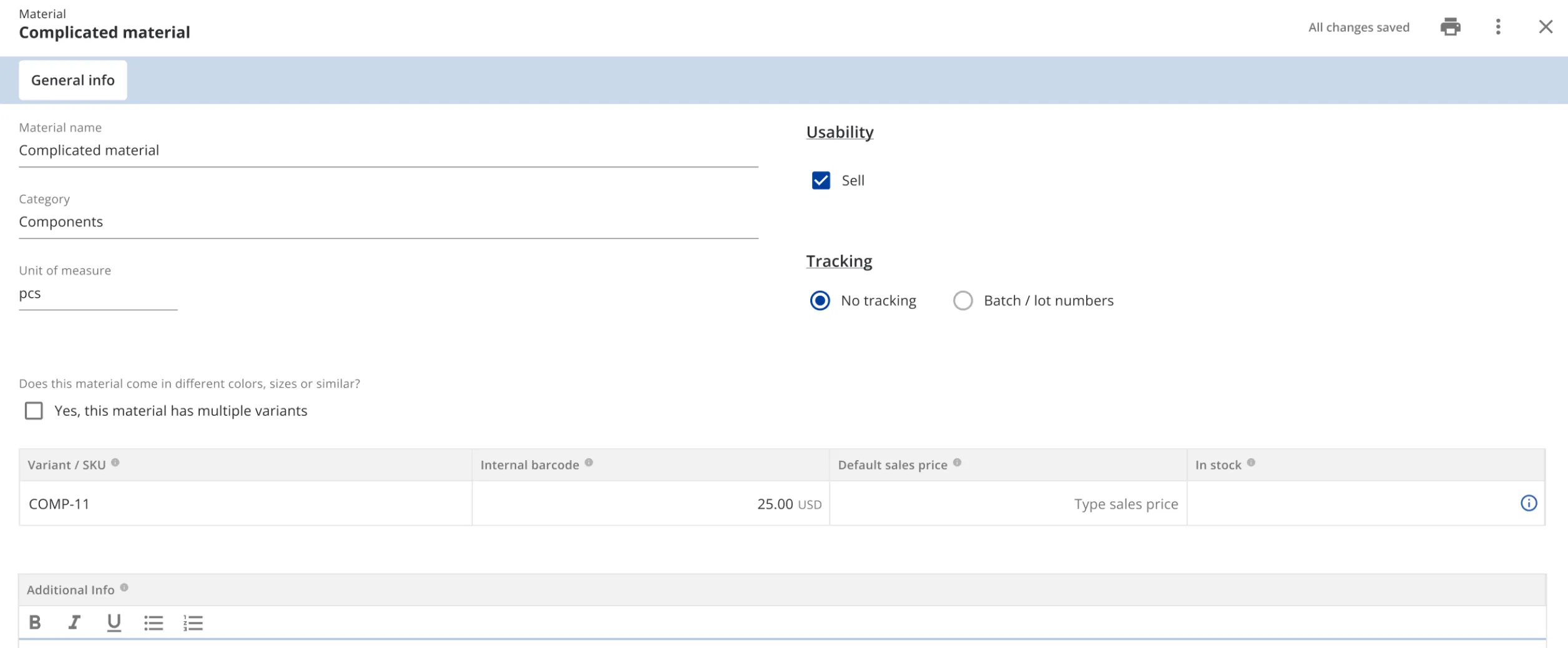

1. Controlata - Intuitive Production Management

Best for: Small to mid-size manufacturers prioritizing ease of use and quick implementation

Controlata stands out with its exceptionally intuitive interface that minimizes learning curves. New users become productive within days, not weeks, thanks to thoughtful design that matches natural manufacturing workflows.

Key Manufacturing Features:

- Bill of Materials Management: Complete BOM tracking with materials, labor costs, equipment depreciation

- Automatic Cost Calculation: Real-time production costing with FIFO inventory valuation

- Production Planning: Material availability checking before production orders

- Multi-location Support: Track inventory across multiple production facilities

Implementation: 1-2 weeks typical deployment

Pricing: From $34/month (Starter) to $129/month (Professional)

Best Fit: Manufacturers with 50-2,000 SKUs needing user-friendly production tracking without complex integrations

2. Katana MRP - Visual Production Planning

Best for: Manufacturers requiring advanced production scheduling and forecasting

Katana excels at visual workflow management with drag-and-drop production scheduling. Their system automatically calculates material requirements and highlights potential bottlenecks before they impact delivery dates.

Key Manufacturing Features:

- Real-time Production Planning: Visual Gantt charts with capacity constraints

- Smart Reordering: Automatic purchase orders based on production schedules

- Live Inventory Updates: Stock levels update instantly as production progresses

- Unlimited Users/SKUs: No restrictions on team size or product complexity

Implementation: 4-6 weeks with training

Pricing: $179-$1,799/month depending on features

Best Fit: Growing manufacturers with complex production workflows and multiple product lines

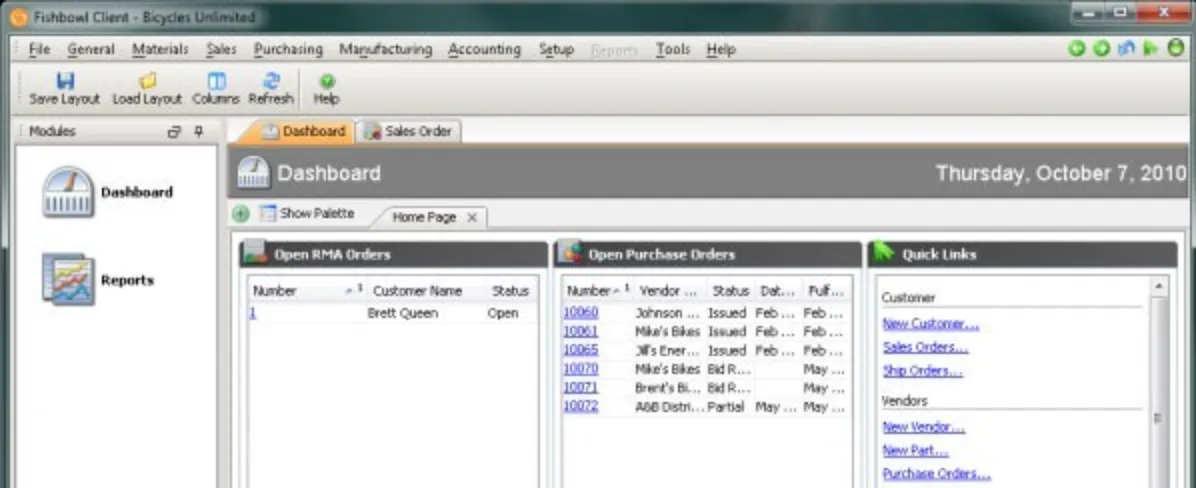

3. Fishbowl - QuickBooks-Integrated Manufacturing

Best for: Manufacturers already using QuickBooks who need manufacturing capabilities

Fishbowl provides the deepest QuickBooks integration available, automatically syncing inventory transactions with financial records. This eliminates double-entry and ensures accurate cost accounting.

Key Manufacturing Features:

- Native QuickBooks Sync: Seamless financial integration with automatic posting

- Advanced Barcode Scanning: Mobile and desktop scanning for production tracking

- Multi-location Management: Track inventory across warehouses and work centers

- Comprehensive Reporting: Manufacturing-specific reports for cost analysis

Implementation: 6-8 weeks including QuickBooks integration

Pricing: $329-$429/month depending on manufacturing complexity

Best Fit: Established manufacturers with complex accounting requirements and multiple locations

Manufacturing-Specific Implementation Considerations

Data Migration Complexity: Manufacturing systems require importing existing BOMs, routing data, and historical cost information. Plan 4-6 weeks for data cleanup and validation.

Training Requirements: Production staff need hands-on training with barcode scanners and mobile devices. Budget 40-60 hours of training time across all users.

Ease of Use Priority: Focus first on solutions with intuitive interfaces and minimal learning curves. Complex systems with steep adoption barriers often fail despite advanced features.

Manufacturing inventory software success depends on accurate BOM setup and consistent production processes. The payoff: 15-25% reduction in material waste and 20-30% improvement in delivery accuracy within the first year.

Retail Inventory Software: Multi-Channel Mastery

Retail inventory management requires juggling multiple sales channels, seasonal fluctuations, and customer expectations for instant availability. 73% of retail small businesses struggle with multi-location inventory visibility, leading to stockouts in one location while overstocking in another.

Critical Retail Requirements

Omnichannel Synchronization: Modern retail demands real-time inventory sync across online stores, physical locations, marketplaces, and social commerce platforms. A customer browsing your website should see accurate stock levels that reflect in-store sales happening simultaneously.

Seasonal Planning and Forecasting: Retail inventory swings dramatically with seasons, holidays, and trends. Systems must analyze historical data, current trends, and external factors to predict demand spikes 3-6 months in advance.

Customer Analytics Integration: Successful retailers track not just what sells, but who buys what, when, and how often. This data drives targeted marketing, personalized recommendations, and strategic inventory placement.

Top 3 Retail Solutions

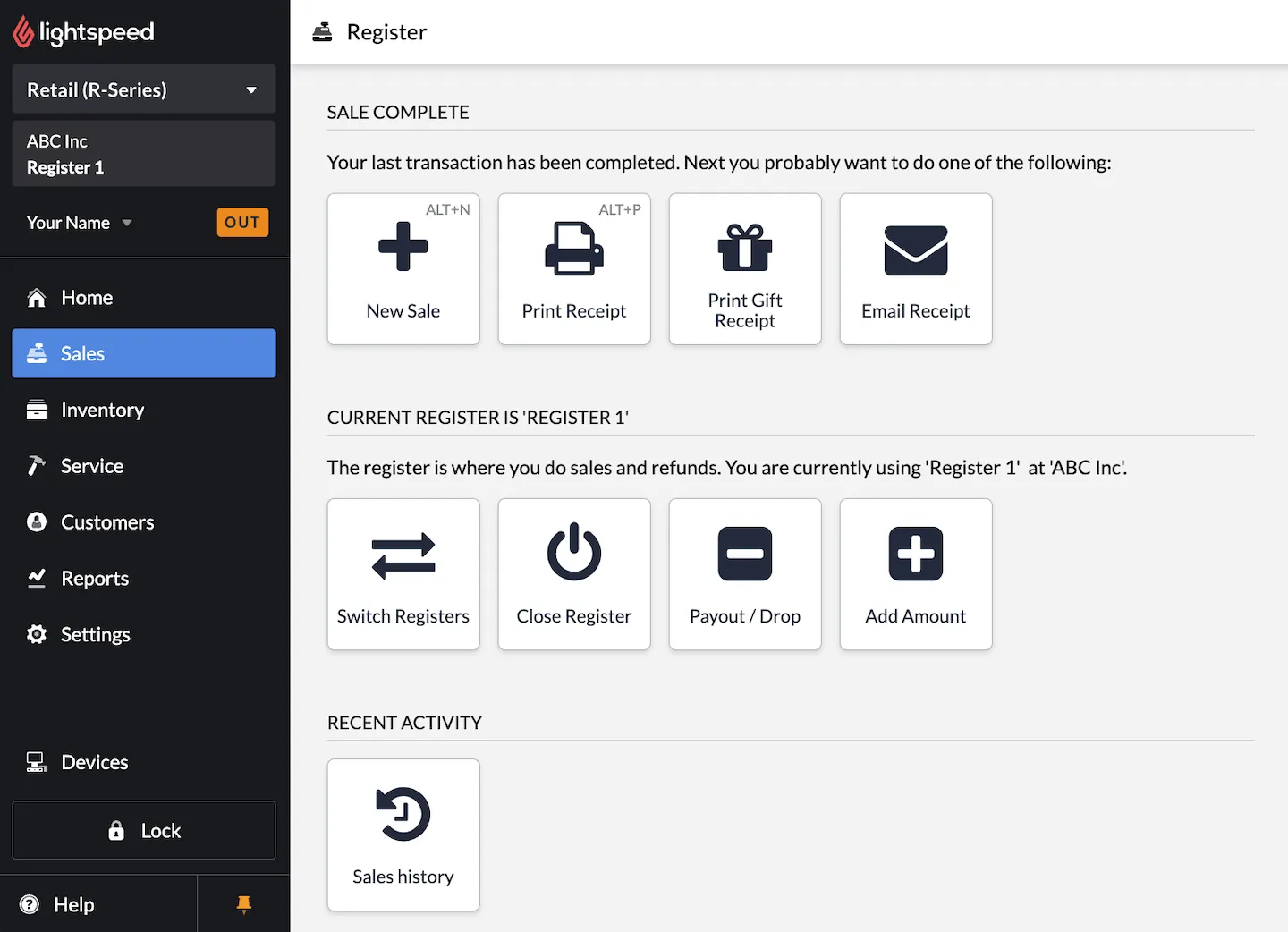

1. Lightspeed Retail - Complete POS Ecosystem

Best for: Multi-location retailers with complex customer loyalty programs

Lightspeed excels at unified POS and inventory management with sophisticated customer relationship features. Their system tracks individual customer purchase history, preferences, and loyalty points across all locations.

Key Retail Features:

- Advanced POS Integration: Native point-of-sale with real-time inventory updates

- Customer Analytics: Purchase history, preferences, and loyalty program management

- Multi-location Sync: Centralized inventory control across unlimited locations

- Seasonal Planning Tools: Historical analysis and demand forecasting for trend prediction

Implementation: 3-4 weeks including POS setup and training

Pricing: $69-$399/month depending on locations and features

Best Fit: Established retailers with 2+ locations needing comprehensive customer management

2. Cin7 - Integration Powerhouse

Best for: Retailers selling across multiple online platforms and marketplaces

Cin7 dominates multi-channel integration with over 700+ platform connections including Amazon, eBay, Shopify, WooCommerce, and social commerce platforms. Inventory updates propagate across all channels within minutes.

Key Retail Features:

- Extensive Integrations: Connect with virtually any e-commerce platform or marketplace

- Automated Reordering: Smart purchase orders based on velocity and seasonality

- Demand Forecasting: AI-powered predictions using multi-channel sales data

- Dropshipping Support: Seamless vendor fulfillment with automatic notifications

Implementation: 4-6 weeks for complex multi-channel setups

Pricing: $295-$999/month based on sales volume and integrations

Best Fit: Growing retailers with 5+ sales channels and complex fulfillment needs

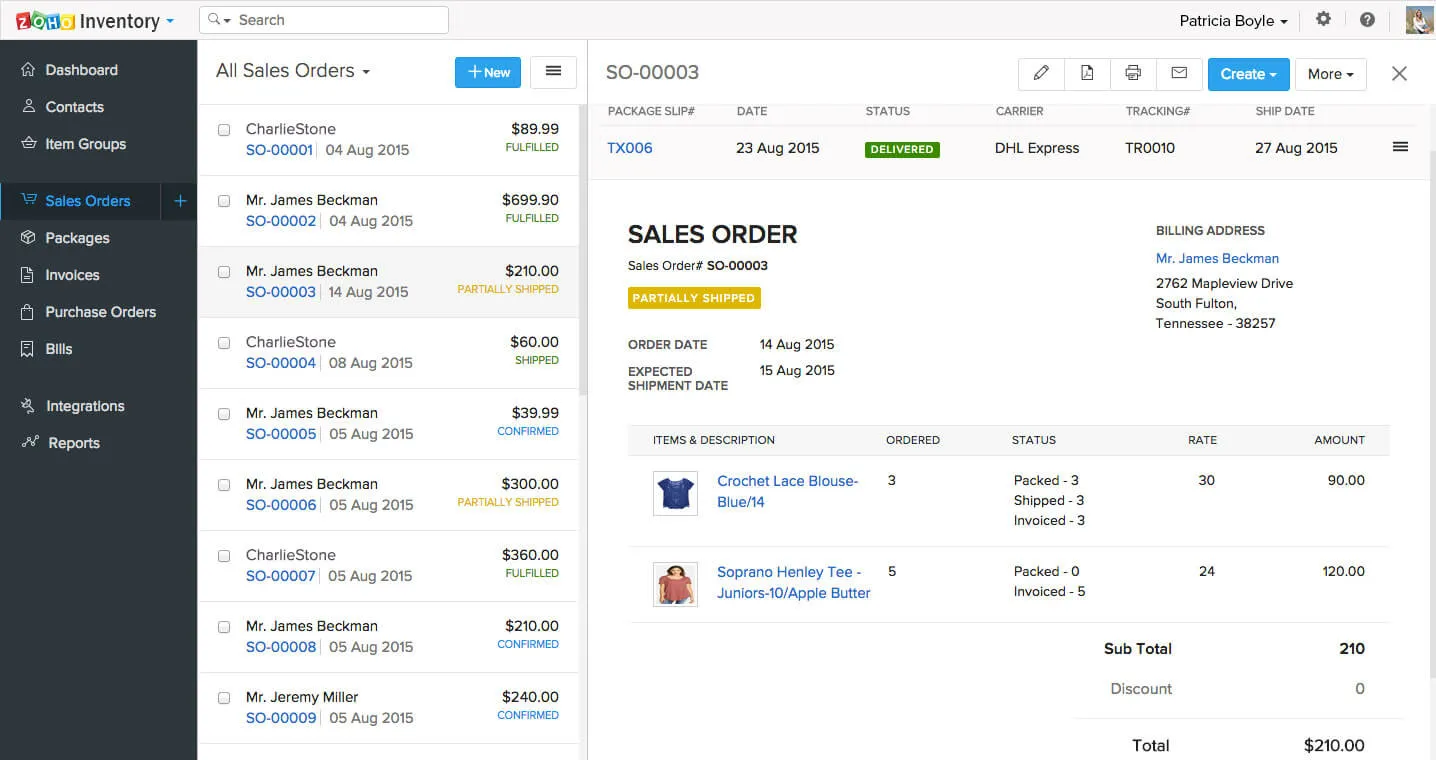

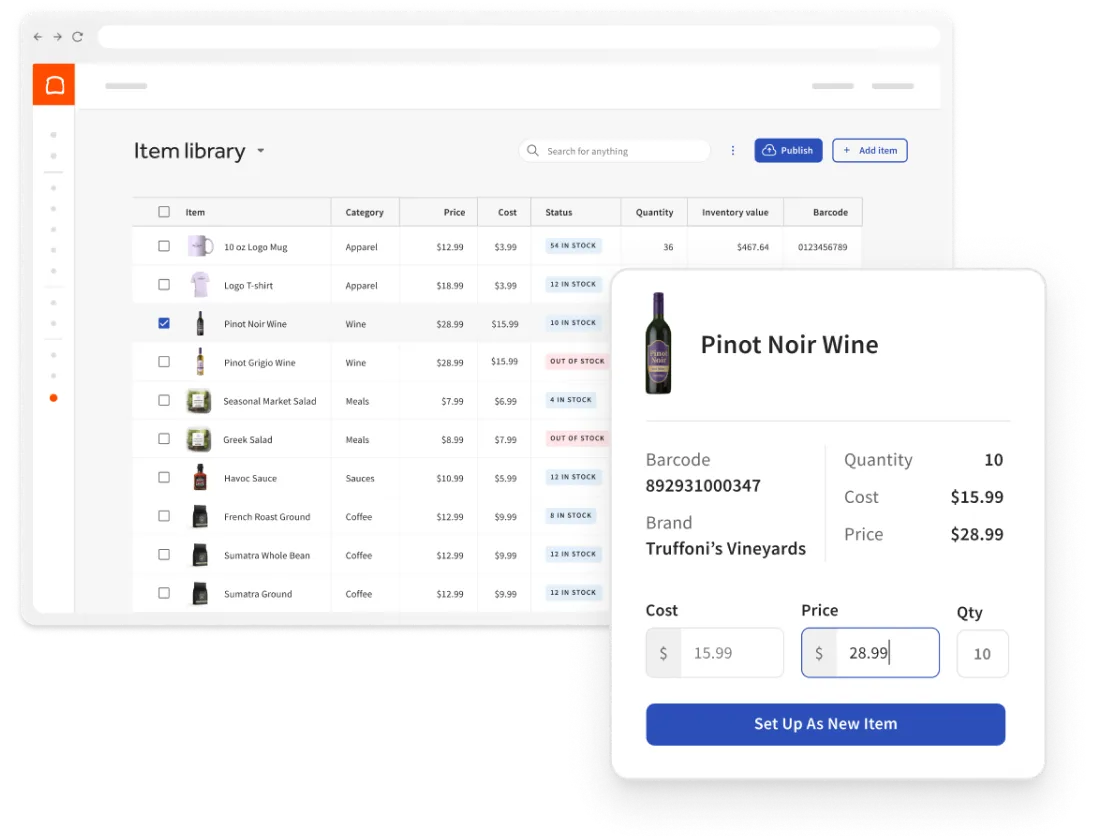

3. Zoho Inventory - Affordable Multi-Platform Management

Best for: Small retailers prioritizing cost-effectiveness without sacrificing functionality

Zoho Inventory delivers enterprise-level features at small business prices. Their platform handles multi-channel selling, automated workflows, and comprehensive reporting at a fraction of competitor costs.

Key Retail Features:

- Multi-platform Selling: Sync with major e-commerce platforms and marketplaces

- Real-time Tracking: Live inventory updates across all sales channels

- Automated Workflows: Purchase orders, low-stock alerts, and reorder point management

- Comprehensive Reporting: Sales analytics, inventory valuation, and profitability analysis

Implementation: 2-3 weeks for standard retail setups

Pricing: $0-$249/month with generous free tier options

Best Fit: Small to medium retailers with budget constraints needing reliable multi-channel management

Retail-Specific Implementation Considerations

Channel Prioritization Strategy: Start with your highest-volume sales channel for initial setup, then add secondary channels incrementally. This approach reduces complexity and ensures core operations remain stable.

Seasonal Data Requirements: Retail systems need minimum 2 years of historical data for accurate demand forecasting. Plan data migration carefully to preserve seasonal patterns and customer purchase histories.

Staff Training Focus: Retail employees need training on mobile scanning, customer lookup, and real-time stock checking. Budget 20-30 hours of hands-on training across all customer-facing staff.

Loss Prevention Integration: Modern retail systems should connect with security cameras, RFID systems, and shrinkage tracking tools. Shrinkage averages 1.6% of sales for retail, making prevention features essential.

Successful retail inventory software transforms chaotic multi-channel operations into streamlined, profitable systems. Retailers typically see 25-35% reduction in stockouts and 15-20% improvement in inventory turnover within the first year.

Restaurant Inventory Software: Food-Specific Features

Restaurant inventory management is uniquely complex due to perishable ingredients, fluctuating food costs, and strict compliance requirements. Food costs typically consume 28-35% of restaurant revenue, making precise tracking essential for profitability.

Critical Restaurant Requirements

Perishable Inventory Tracking: Unlike retail or manufacturing, restaurant inventory has expiration dates that directly impact food safety and profitability. Systems must track shelf life, automatically rotate stock using FIFO methodology, and alert managers before spoilage occurs.

Recipe Costing with Real-Time Pricing: Menu profitability changes daily as ingredient costs fluctuate. A burger that costs $3.20 to make on Monday might cost $3.85 on Friday due to produce price changes. Systems must recalculate recipe costs in real-time based on current ingredient prices.

Waste Management and Loss Prevention: Restaurants lose 4-10% of food inventory to spoilage, over-portioning, and theft. Effective systems track waste by category, identify patterns, and help managers implement corrective actions.

Top 3 Restaurant Solutions

1. Toast Inventory - Integrated POS Ecosystem

Best for: Full-service restaurants with complex menus and multiple locations

Toast provides seamless POS integration where every sale automatically updates ingredient usage based on recipe specifications. Their system calculates real-time food costs and identifies unprofitable menu items instantly.

Key Restaurant Features:

- Recipe Costing: Automatic menu profitability calculation with real-time ingredient pricing

- Automated Ordering: Generate purchase orders based on consumption patterns and upcoming reservations

- Waste Tracking: Document and categorize all food waste with photo capture and reason codes

- Prep Management: Track prep item production and usage across kitchen stations

Implementation: 2-3 weeks including POS integration and staff training

Pricing: $69-$165/month per location plus hardware costs

Best Fit: Established restaurants with complex menus needing comprehensive food cost control

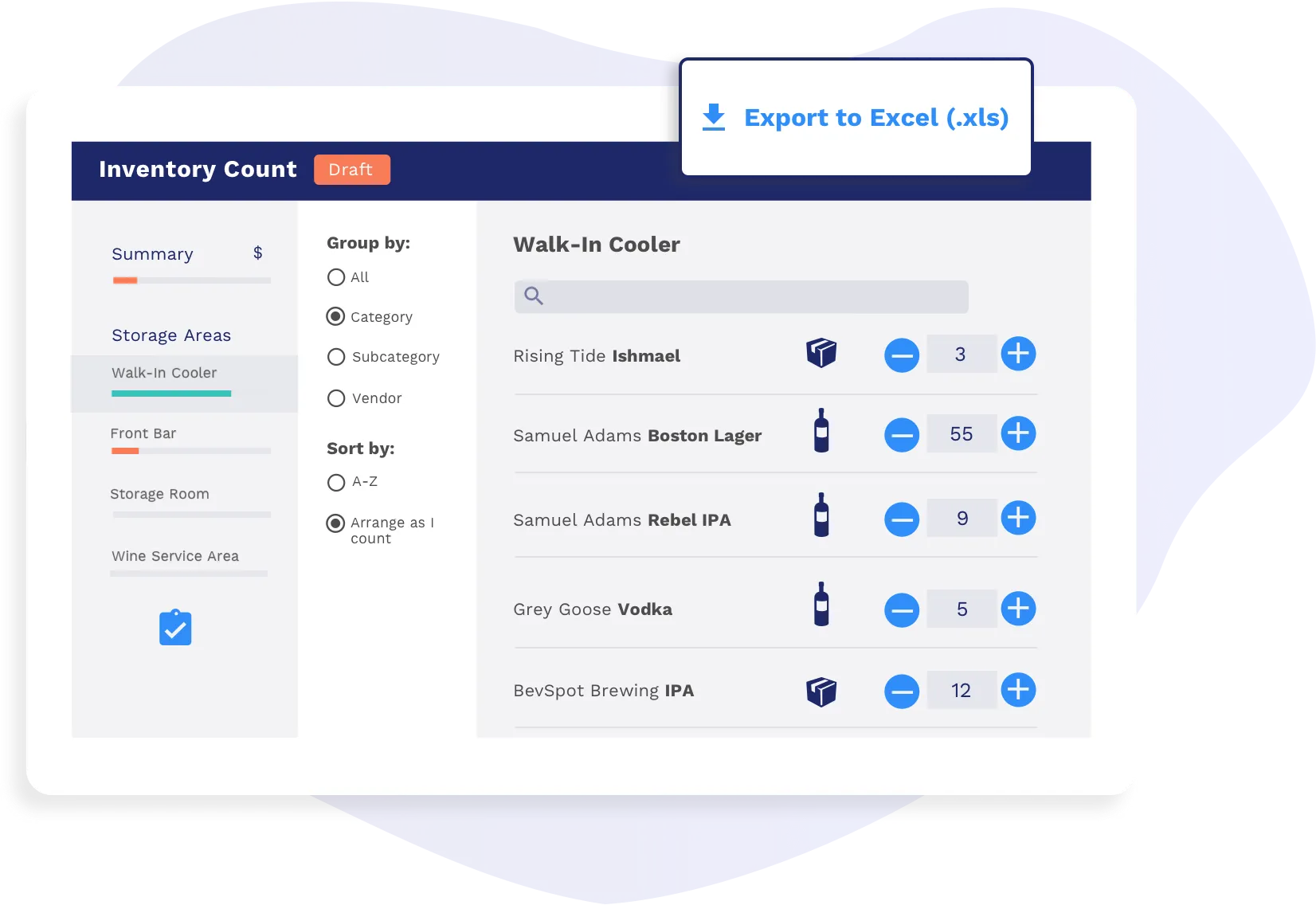

2. BevSpot - Bar and Restaurant Specialization

Best for: Bars, breweries, and restaurants with significant alcohol inventory

BevSpot excels at liquor inventory management with specialized features for kegs, bottles, and draft systems. Their variance reporting identifies over-pouring, theft, and inventory discrepancies with precision.

Key Restaurant Features:

- Liquor Inventory Control: Track beer kegs, wine bottles, and spirits with pour cost analysis

- Mobile Scanning: Smartphone-based barcode scanning for quick inventory counts

- Variance Reporting: Identify discrepancies between expected and actual usage patterns

- Supplier Integration: Connect directly with distributors for automated ordering and pricing updates

Implementation: 1-2 weeks with minimal disruption to operations

Pricing: $79-$249/month depending on location count and features

Best Fit: Bars and restaurants where alcohol represents 20%+ of total inventory value

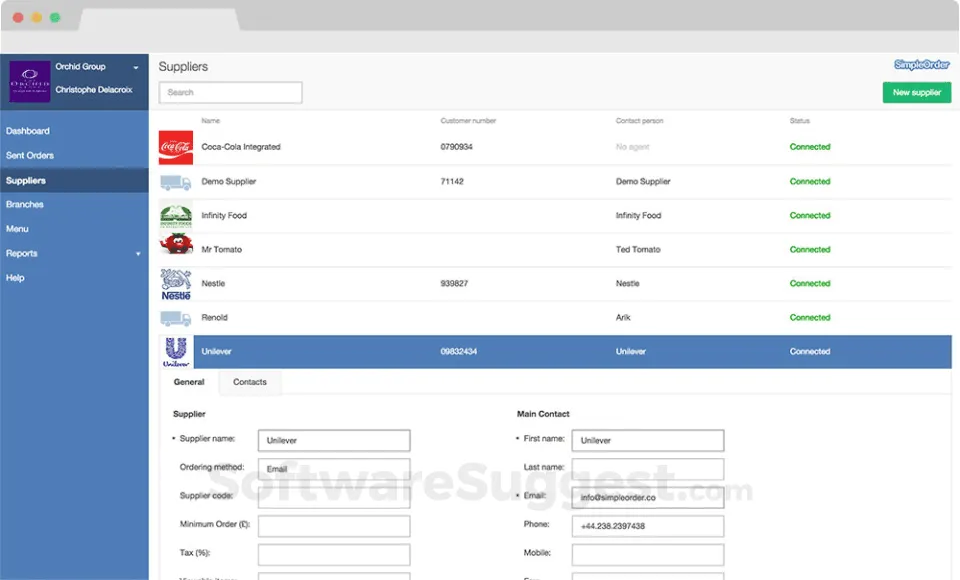

3. SimpleOrder - Vendor Management Focus

Best for: Independent restaurants prioritizing supplier relationship management

SimpleOrder streamlines vendor communication and ordering processes with direct integration to major food distributors. Their platform consolidates orders across multiple suppliers into unified workflows.

Key Restaurant Features:

- Multi-Vendor Ordering: Place orders with multiple suppliers through single interface

- Cost Analysis: Track price changes and negotiate better terms with historical data

- Menu Profitability: Real-time recipe costing with automatic price updates from suppliers

- Delivery Management: Schedule and track deliveries with automated receiving workflows

Implementation: 1-2 weeks focusing on vendor setup and integration

Pricing: $99-$299/month based on order volume and vendor connections

Best Fit: Independent restaurants with 3+ suppliers needing streamlined purchasing workflows

Restaurant-Specific Implementation Considerations

Menu Engineering Priority: Start implementation with your 20 highest-volume menu items to immediately impact food costs. These items typically represent 60-70% of total food sales and provide quick ROI.

Staff Training Requirements: Kitchen staff need training on proper portioning, waste documentation, and mobile scanning. Front-of-house staff require POS integration training. Budget 15-25 hours of training across all roles.

Compliance Integration: Restaurant systems must support HACCP compliance, allergen tracking, and local health department requirements. Ensure your chosen solution provides audit trails and food safety documentation.

Peak Hour Performance: Restaurant systems must handle order volume spikes during rush periods without slowing POS operations. Test system performance during peak hours before full deployment.

Restaurant inventory software transforms chaotic kitchen operations into data-driven profit centers. Restaurants typically see 3-7% reduction in food costs and 25-40% decrease in food waste within the first six months of implementation.

Choosing the Right Solution: Decision Framework

Selecting inventory software requires systematic evaluation beyond feature lists and pricing tables. 68% of small business software implementations fail due to poor planning and misaligned expectations.

Step-by-Step Selection Process

1. Requirements Assessment

Identify your core needs based on industry complexity. Manufacturing requires BOM tracking and production scheduling. Retail needs multi-channel synchronization and customer analytics. Restaurants must handle perishables and recipe costing.

2. Scalability Planning

3-Year Growth Questions:

- How many additional SKUs will you manage?

- What new sales channels will you add?

- How many locations will you operate?

Scalability Red Flags:

- Per-transaction pricing models (expensive as you grow)

- User license limitations (restricts team expansion)

- Feature restrictions on lower tiers

3. Total Cost Evaluation

Visible Costs: Monthly licensing, implementation fees, training costs

Hidden Costs: Data migration services ($2,000-$8,000), custom development ($5,000-$15,000+), staff productivity loss during transition

Making the Final Decision

Focus on solutions that match your industry’s specific workflows and complexity level. Solutions like Controlata excel with ease of use and quick implementation, while enterprise platforms offer advanced features at higher complexity costs.

The right inventory software transforms operations from reactive firefighting to proactive planning. Success depends on thorough planning, realistic expectations, and commitment to staff training rather than software features alone.