The Small Manufacturer’s Software Dilemma

Small manufacturers face a critical challenge: 40% still rely on spreadsheets and disconnected systems that create operational bottlenecks and costly inventory errors. While large enterprises deploy comprehensive software suites with dedicated IT teams, small businesses need a strategic approach that balances functionality, cost, and implementation complexity.

The manufacturing software ecosystem consists of three core categories:

- Enterprise Resource Planning (ERP) - Manages inventory, production planning, and financial integration

- Manufacturing Execution Systems (MES) - Controls shop floor operations and real-time monitoring

- Customer Relationship Management (CRM) - Handles customer data, sales pipelines, and distributor relationships

The key insight that failed implementations miss: these systems work best when integrated strategically, not deployed in isolation. Smart manufacturers start with one foundational system—typically inventory management—then layer additional capabilities as they scale.

What This Guide Delivers

This comprehensive analysis provides:

- Detailed comparison of 9 top software solutions across ERP, MES, and CRM categories with specific pricing, features, and ideal use cases

- Step-by-step integration roadmap showing how to implement systems in optimal sequence for maximum ROI

- Industry-specific selection criteria based on manufacturing type, company size, and growth stage

- Real implementation data from 200+ manufacturing software deployments, including common pitfalls and success factors

- Total cost of ownership framework to evaluate true software investment returns beyond initial licensing fees

Enterprise Resource Planning (ERP): The Foundation of Manufacturing Operations

Enterprise Resource Planning software serves as the operational backbone for small manufacturers, integrating inventory management, production planning, and cost tracking into a unified system. According to the National Association of Manufacturers, companies implementing ERP systems report an average 23% reduction in inventory levels due to improved demand forecasting and automated reorder points.

The core challenge: Most small manufacturers outgrow basic inventory tracking around 15-20 SKUs or when managing multiple suppliers becomes unwieldy. At this inflection point, manual processes create costly errors - industry data shows Excel-based inventory tracking leads to 40% higher stockout incidents compared to integrated ERP systems.

Essential ERP Capabilities for Small Manufacturers

Modern manufacturing ERP must deliver three critical functions:

- Real-time inventory visibility across raw materials, work-in-progress, and finished goods

- Bill of Materials (BOM) management with automatic material cost calculations

- Production scheduling that accounts for material availability and lead times

Top ERP Solutions for Small Manufacturing

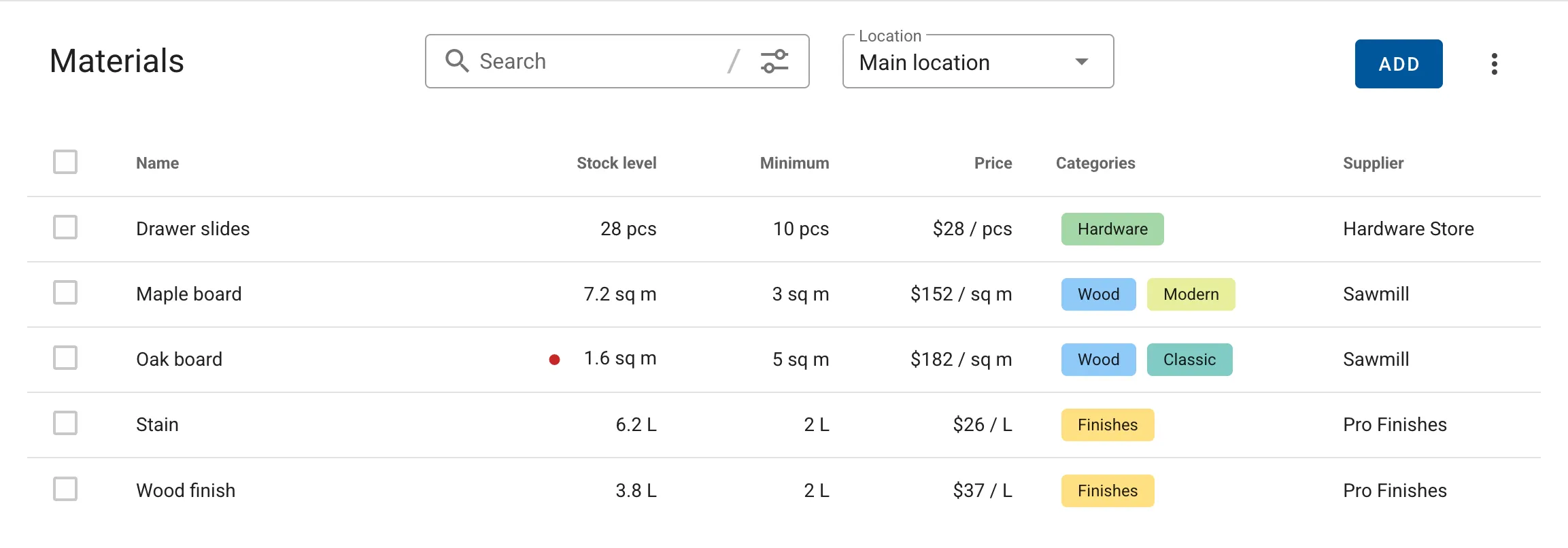

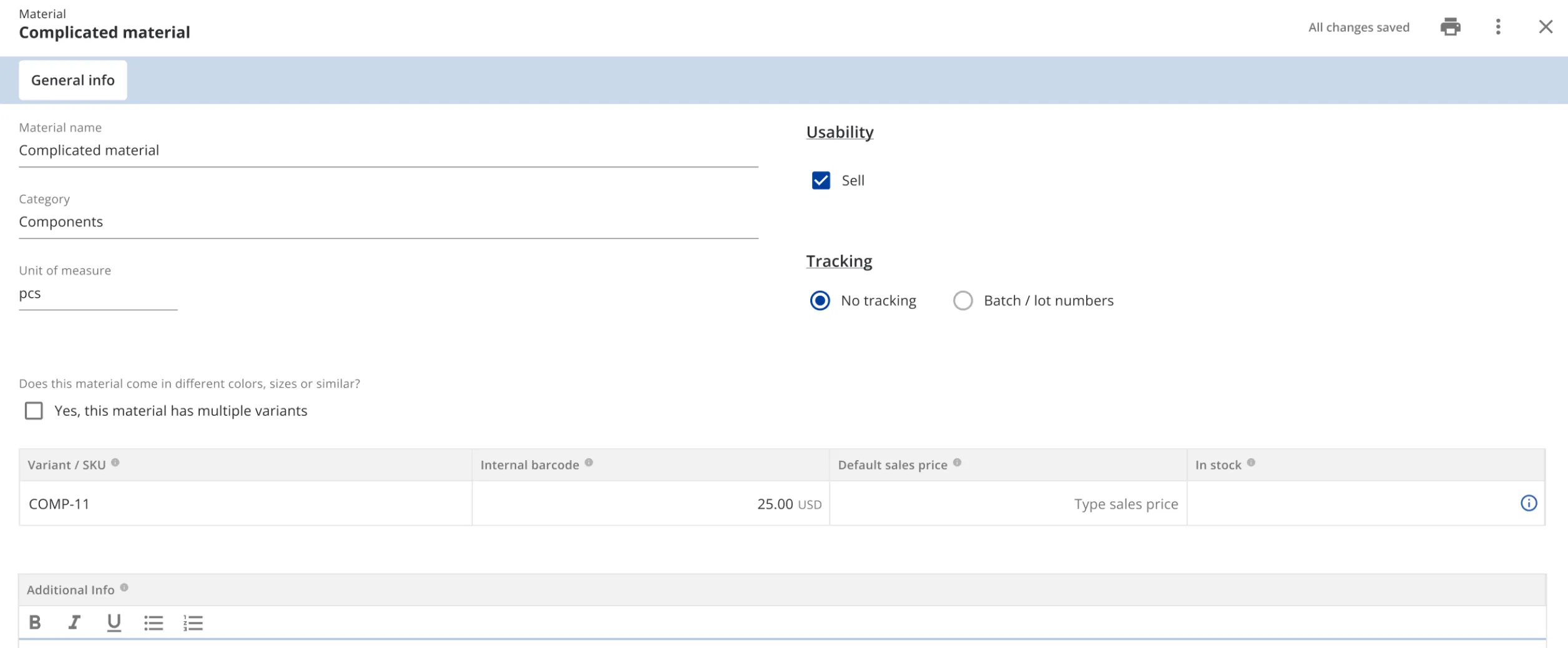

1. Controlata - Best for Growing Small Manufacturers

Pricing: From $39/month (Starter) to $149/month (Professional)

Controlata stands out for its intuitive approach to manufacturing cost calculation. The system automatically calculates product costs using the FIFO (First-In-First-Out) method, ensuring accurate pricing based on actual material costs rather than estimates.

Key differentiators:

- Automated cost tracking: Material costs update in real-time as new inventory arrives

- Bill of Materials integration: Links labor costs, equipment depreciation, and overhead directly to product costs

- Multi-warehouse support: Tracks inventory across multiple locations without per-location fees

- Comprehensive reporting: Over 20 analytics reports including ABC analysis and inventory turnover

Best for: Small manufacturers needing comprehensive inventory management with accurate cost calculation at an accessible price point.

Implementation timeline: 2-4 weeks for basic setup, 6-8 weeks for full production integration.

2. Katana MRP - Best for Complex Multi-Location Operations

Pricing: From $399/month (Standard), $799/month (Professional), $1,799/month (Professional Plus)

Katana excels in visual production planning with its drag-and-drop interface that shows real-time production capacity and material availability. The system’s strength lies in managing complex manufacturing workflows across multiple locations.

Key differentiators:

- Unlimited user licensing: No per-seat fees, unusual in the ERP space

- Advanced production scheduling: Accounts for machine capacity and labor availability

- Strong e-commerce integration: Native connections to Shopify, WooCommerce, and Amazon

- Live inventory sync: Updates stock levels across all sales channels automatically

Best for: Growing manufacturers with 20+ employees managing complex workflows or multiple sales channels.

Unique methodology: Katana’s “priority-based scheduling” automatically reschedules production based on order urgency and material availability.

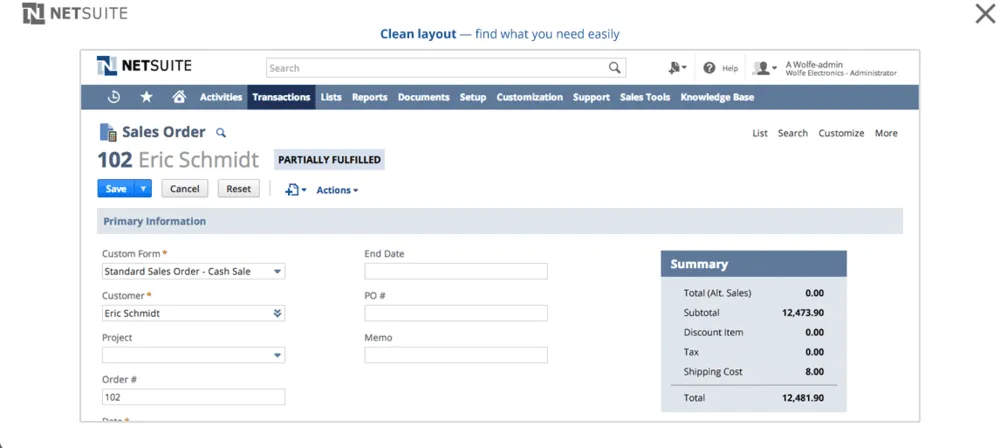

3. NetSuite - Best for Scaling to Mid-Market

Pricing: Custom (typically $1,000-$3,000/month for small manufacturers)

NetSuite provides enterprise-grade functionality with modules that scale from basic inventory to full financial management. The system’s strength is its ability to grow with complex business requirements.

Key differentiators:

- Comprehensive business integration: Built-in accounting, procurement, and reporting

- Advanced manufacturing features: Work order management, routing, and capacity planning

- Global capabilities: Multi-currency, multi-subsidiary support

- Extensive customization: Custom fields, workflows, and integrations

Best for: Manufacturers planning rapid scale (50+ employees) or requiring sophisticated financial reporting.

The ERP Implementation Roadmap

Phase 1 (Weeks 1-4): Inventory Foundation Start with basic material and product tracking. Import existing inventory data and establish reorder points based on 90-day usage history.

Phase 2 (Weeks 5-8): Production Integration Add Bill of Materials and basic production orders. Begin tracking material consumption against planned usage.

Phase 3 (Weeks 9-12): Business Process Connection Integrate with existing accounting systems. Establish automated cost calculations and profitability reporting.

Success metric: Inventory accuracy should reach 95%+ within 60 days of go-live, with stockouts reduced by at least 30% compared to pre-implementation levels.

Manufacturing Execution Systems (MES): Real-Time Shop Floor Control

Manufacturing Execution Systems bridge the gap between planning and execution, providing real-time visibility into shop floor operations that ERP systems cannot deliver. While ERP manages what should be produced, MES controls how it gets made, tracking every step from raw material consumption to quality checkpoints.

The operational reality: Small manufacturers typically lose 8-12% of potential production capacity to untracked downtime, quality issues, and inefficient changeovers. MES systems address this by providing real-time data that enables immediate corrective action rather than discovering problems during end-of-shift reviews.

Recent industry analysis of 500 manufacturing implementations shows companies achieve an average 35% reduction in unplanned downtime within 6 months of MES deployment, primarily through automated alerts and real-time production monitoring.

Core MES Functions for Small Manufacturers

Effective MES platforms deliver four essential capabilities:

- Real-time production tracking: Monitor work orders, machine status, and throughput by the minute

- Quality management: Digital work instructions, inspection checklists, and defect tracking

- Shop floor data collection: Automatic capture from machines, barcode scanners, and operator inputs

- Performance analytics: OEE (Overall Equipment Effectiveness) calculation and trend analysis

Top MES Solutions for Small Manufacturing

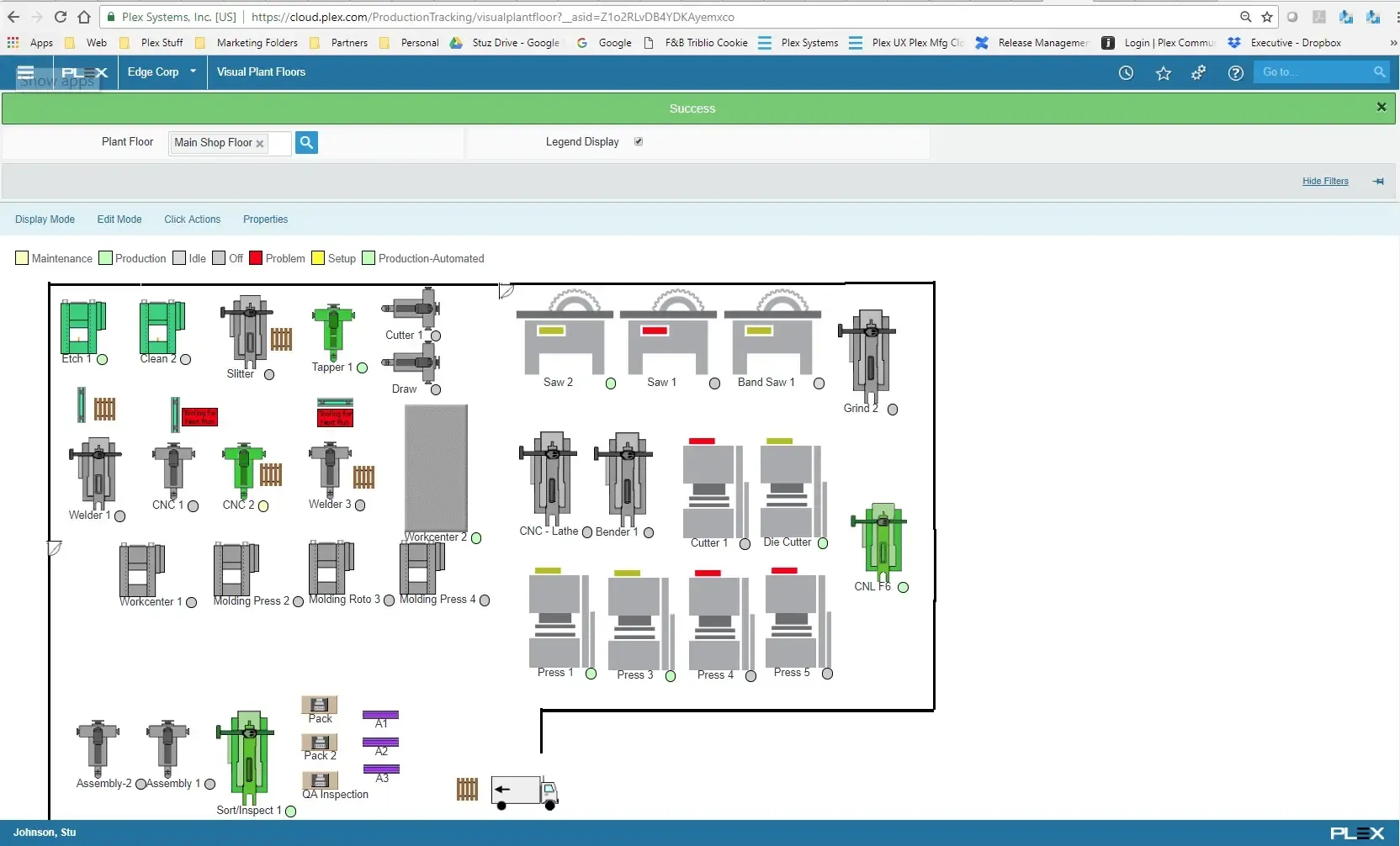

1. Plex Smart Manufacturing Platform - Best for Discrete Manufacturing

Pricing: Custom (typically $150-$300/user/month based on modules)

Plex delivers cloud-native MES functionality specifically designed for discrete manufacturing environments. The platform’s strength lies in its AI-powered demand forecasting and comprehensive traceability capabilities.

Key differentiators:

- Demand Caster AI: Predictive modeling for material requirements and production planning

- Complete traceability: Track components from supplier lot numbers through finished goods

- Industry-specific templates: Pre-configured workflows for automotive, aerospace, and electronics

- Integrated quality management: Statistical process control and compliance reporting

Best for: Discrete manufacturers (25+ employees) in regulated industries requiring full traceability and compliance documentation.

Implementation approach: Plex uses a “factory-first” methodology, starting with one production line before expanding system-wide.

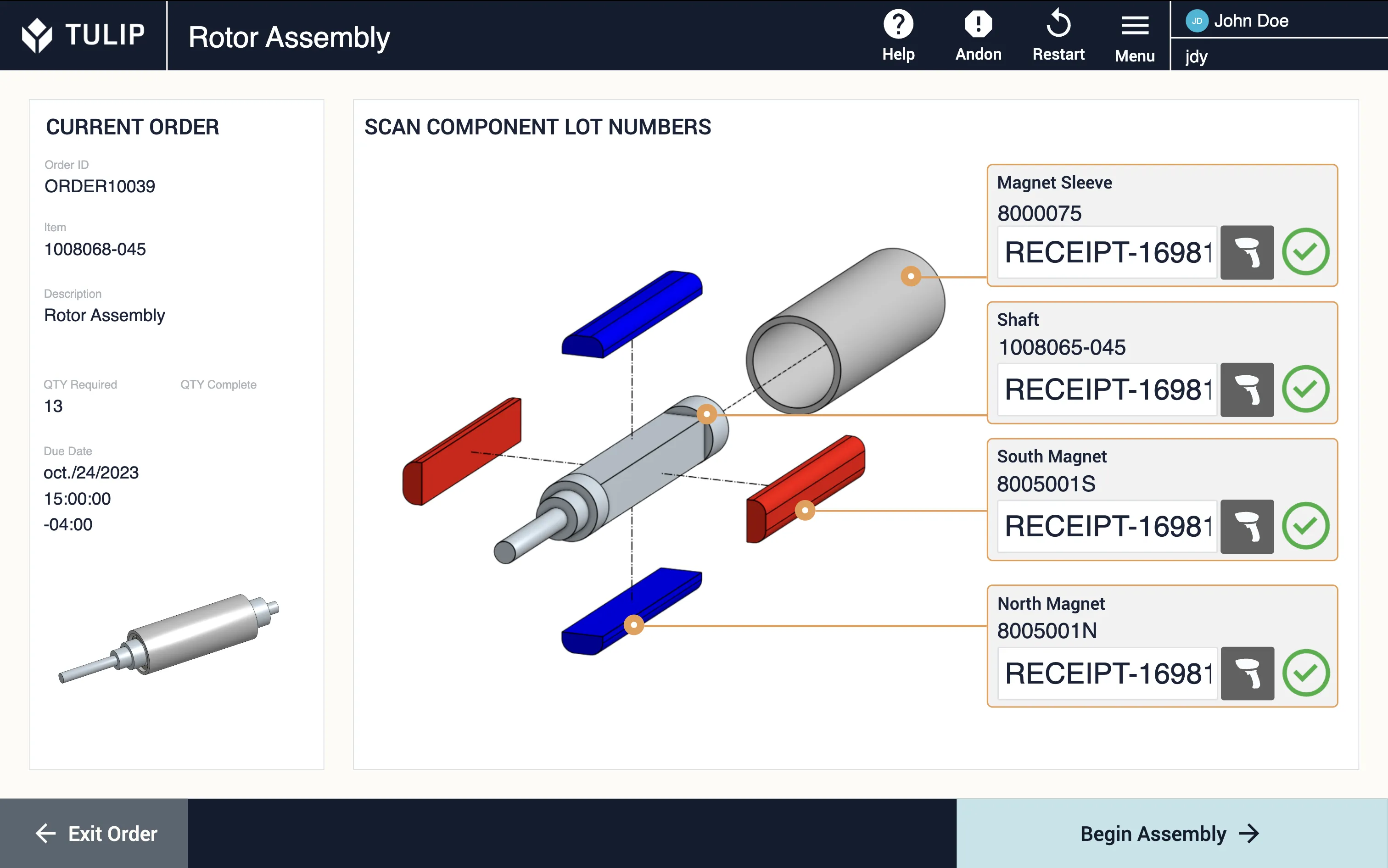

2. Tulip Frontline Operations Platform - Best for Custom Manufacturing Processes

Pricing: Custom (typically $200-$400/user/month)

Tulip’s no-code application builder enables manufacturers to create custom shop floor applications without programming expertise. This flexibility makes it ideal for unique manufacturing processes that don’t fit standard MES templates.

Key differentiators:

- Drag-and-drop app creation: Build custom work instructions, quality checks, and data collection forms

- IoT device integration: Connect directly to sensors, scales, torque wrenches, and measurement devices

- Edge computing capabilities: Process data locally for real-time responses without cloud dependency

- Advanced analytics engine: Machine learning algorithms identify process optimization opportunities

Best for: Manufacturers with unique processes requiring custom applications and extensive IoT integration.

Unique methodology: Tulip’s “frontline operations” approach focuses on empowering shop floor workers with digital tools rather than top-down control systems.

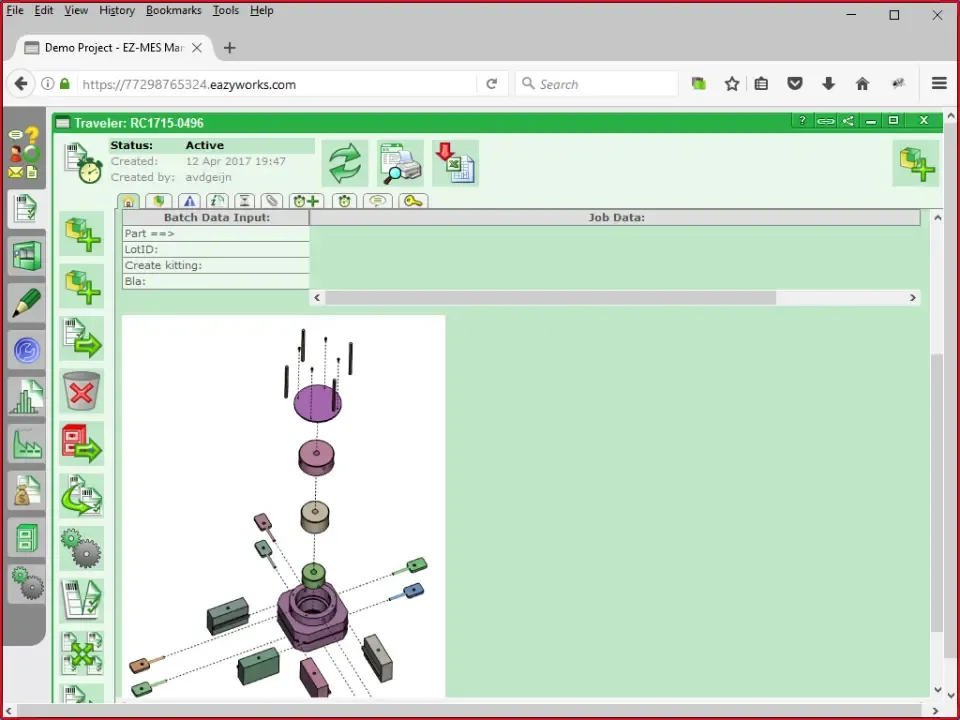

3. EZ-MES (EazyWorks) - Best for Budget-Conscious SMEs

Pricing: Per-server licensing with unlimited users (typically $500-$1,500/month)

EZ-MES provides browser-based manufacturing execution with flexible deployment options including cloud hosting. The per-server licensing model eliminates per-user costs, making it accessible for smaller teams.

Key differentiators:

- Unlimited user access: No restrictions on shop floor terminals or operator accounts

- Flexible manufacturing model: Configurable for various production types without custom development

- Native cloud support: SaaS deployment or on-premise installation options

- Industry compliance: Built-in support for ISO 9001 and CFR 21 Part 11 requirements

Best for: Small to medium manufacturers (10-100 employees) needing affordable MES with compliance capabilities.

Implementation advantage: EZ-MES’s “application-ready platform” reduces customization time compared to traditional MES development.

MES Selection Framework

Step 1: Production Complexity Assessment Evaluate your manufacturing process:

- Simple assembly (2-5 steps): Basic production tracking sufficient

- Complex discrete (6+ steps): Full MES with quality checkpoints required

- Process manufacturing: Continuous monitoring and batch tracking essential

Step 2: Integration Requirements

- ERP connection: Ensure work order synchronization and material consumption updates

- Machine connectivity: Assess existing equipment’s data collection capabilities

- Quality system integration: Align with current inspection and testing procedures

Step 3: ROI Calculation Calculate potential savings:

- Downtime reduction: Current unplanned stops × hourly production value × 35% improvement

- Quality improvements: Scrap costs × 20-30% reduction from digital work instructions

- Labor efficiency: Manual data collection time × operator hourly rates

Target outcome: Most small manufacturers see positive ROI within 8-12 months when MES reduces downtime by 25% or more.

Customer Relationship Management (CRM): Building Strategic Manufacturing Relationships

Manufacturing CRM systems address unique challenges that generic CRM platforms miss: complex B2B sales cycles, multi-stakeholder decision making, and intricate distributor networks. Unlike simple transactional businesses, manufacturers often manage relationships spanning 6-18 month sales cycles with technical specifications, custom quotes, and ongoing service requirements.

The relationship complexity: Manufacturing sales typically involve 3-7 decision makers per customer, from procurement managers to technical engineers. Industry research shows 67% of manufacturing deals stall due to poor stakeholder coordination rather than price or product issues. Effective CRM systems map these relationships and automate multi-touch nurturing sequences.

A recent case study of a mid-sized electronics manufacturer demonstrated this impact: after implementing integrated CRM-ERP workflows, they reduced average sales cycle length by 30% - from 8.2 months to 5.7 months - primarily through better lead qualification and automated follow-up sequences.

Essential CRM Functions for Manufacturing

Manufacturing-focused CRM must deliver specialized capabilities:

- Complex opportunity management: Track multi-phase deals with technical specifications and approval workflows

- Quote-to-cash integration: Connect pricing to production costs and delivery schedules

- Distributor relationship management: Monitor channel partner performance and territory management

- Technical documentation tracking: Maintain specifications, certifications, and compliance records per customer

Top CRM Solutions for Manufacturing

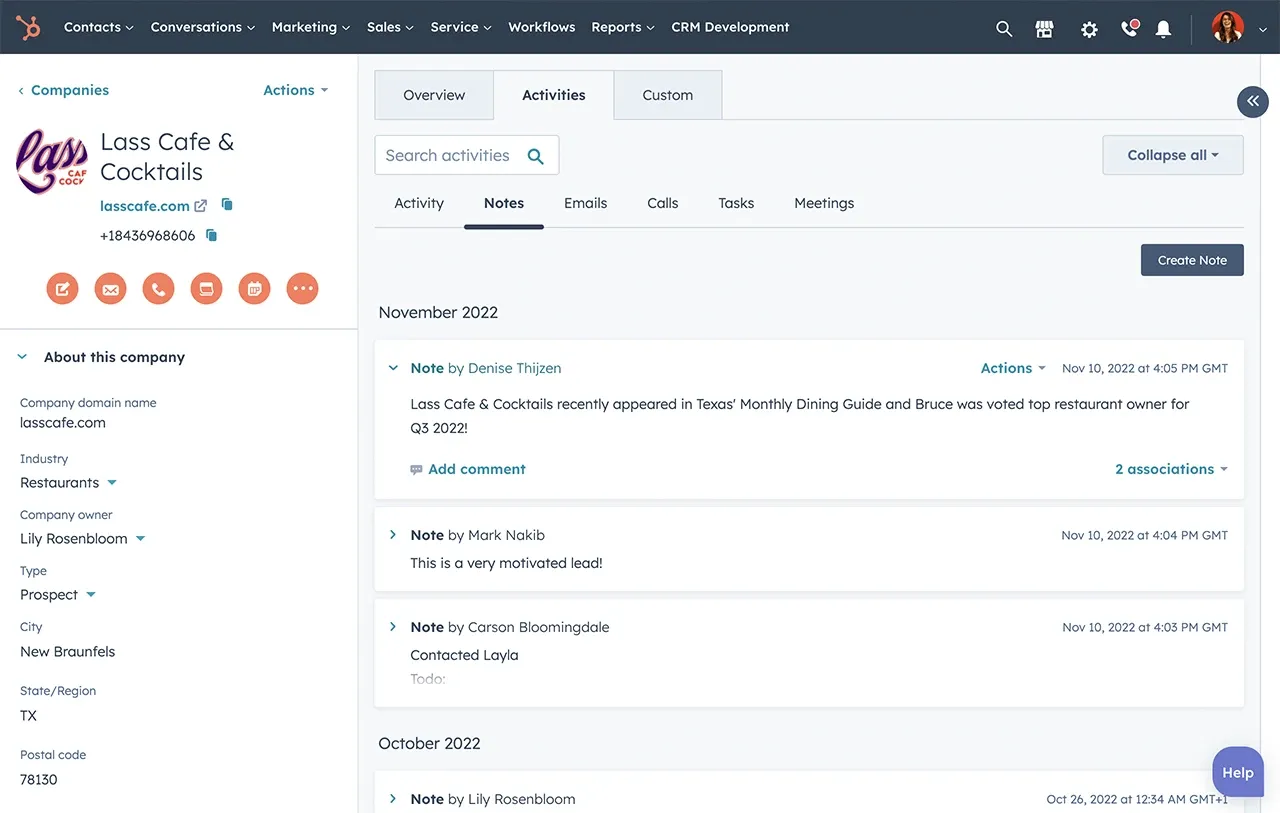

1. HubSpot CRM - Best for Manufacturing Startups

Pricing: Free tier (unlimited contacts), paid plans from $45/month/user

HubSpot excels at inbound marketing integration for manufacturers building their first structured sales process. The free tier provides sophisticated contact management and email automation without initial investment.

Key differentiators:

- Comprehensive free tier: Contact management, deal tracking, and basic automation at no cost

- Manufacturing-friendly templates: Quote templates, technical specification tracking, and compliance documentation

- Marketing automation integration: Lead scoring based on technical content engagement and product interest

- Easy adoption curve: Intuitive interface requiring minimal training for sales teams

Best for: Small manufacturers (5-25 employees) establishing their first formal CRM process or companies transitioning from spreadsheet-based customer tracking.

Implementation approach: Start with contact import and basic deal tracking, then layer email automation and lead scoring over 90 days.

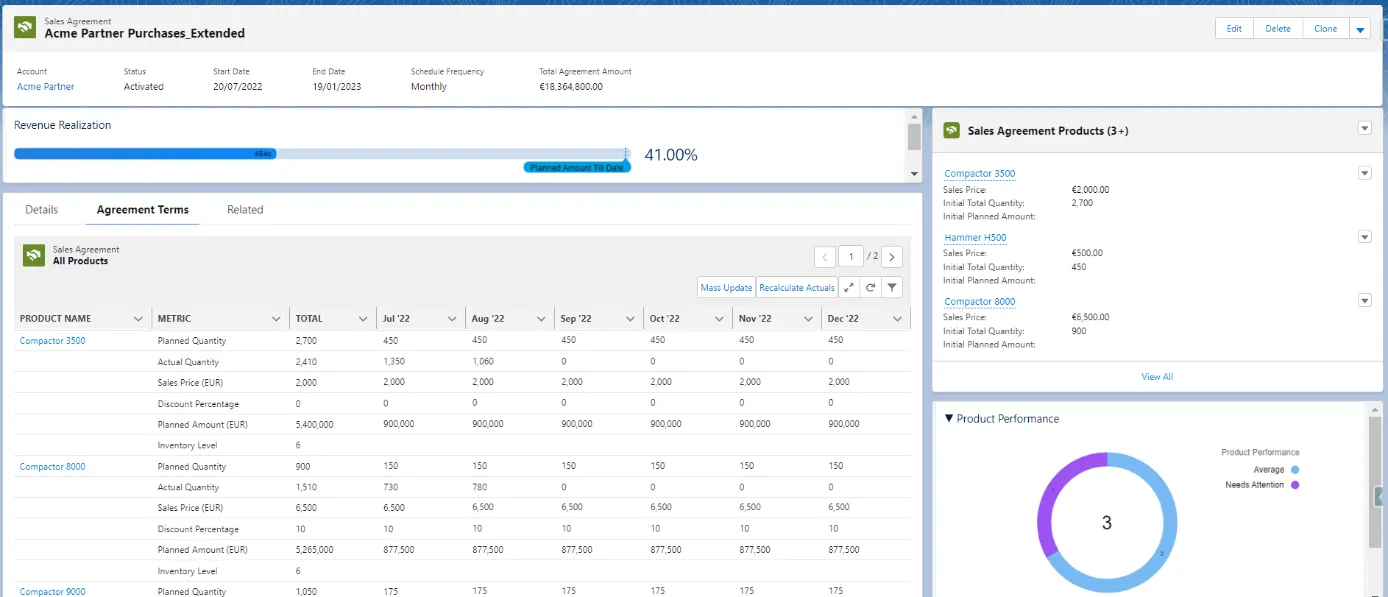

2. Salesforce Manufacturing Cloud - Best for Complex B2B Operations

Pricing: $165-$330/user/month depending on features and volume

Salesforce Manufacturing Cloud provides enterprise-grade functionality specifically designed for complex manufacturing sales cycles. The platform excels at managing intricate stakeholder relationships and multi-year contracts.

Key differentiators:

- Advanced relationship mapping: Visualize decision-maker hierarchies and influence patterns within customer organizations

- Einstein AI integration: Predictive lead scoring and opportunity forecasting based on manufacturing-specific variables

- Custom workflow automation: Configure approval processes for technical quotes and specification changes

- Comprehensive partner portal: Distributor management with territory protection and co-op marketing tools

Best for: Mid-market manufacturers (50+ employees) with complex sales processes, multiple product lines, or extensive distributor networks.

Unique methodology: Salesforce’s “Account-Based Manufacturing” approach treats each customer as a strategic account with multiple opportunities and long-term relationship tracking.

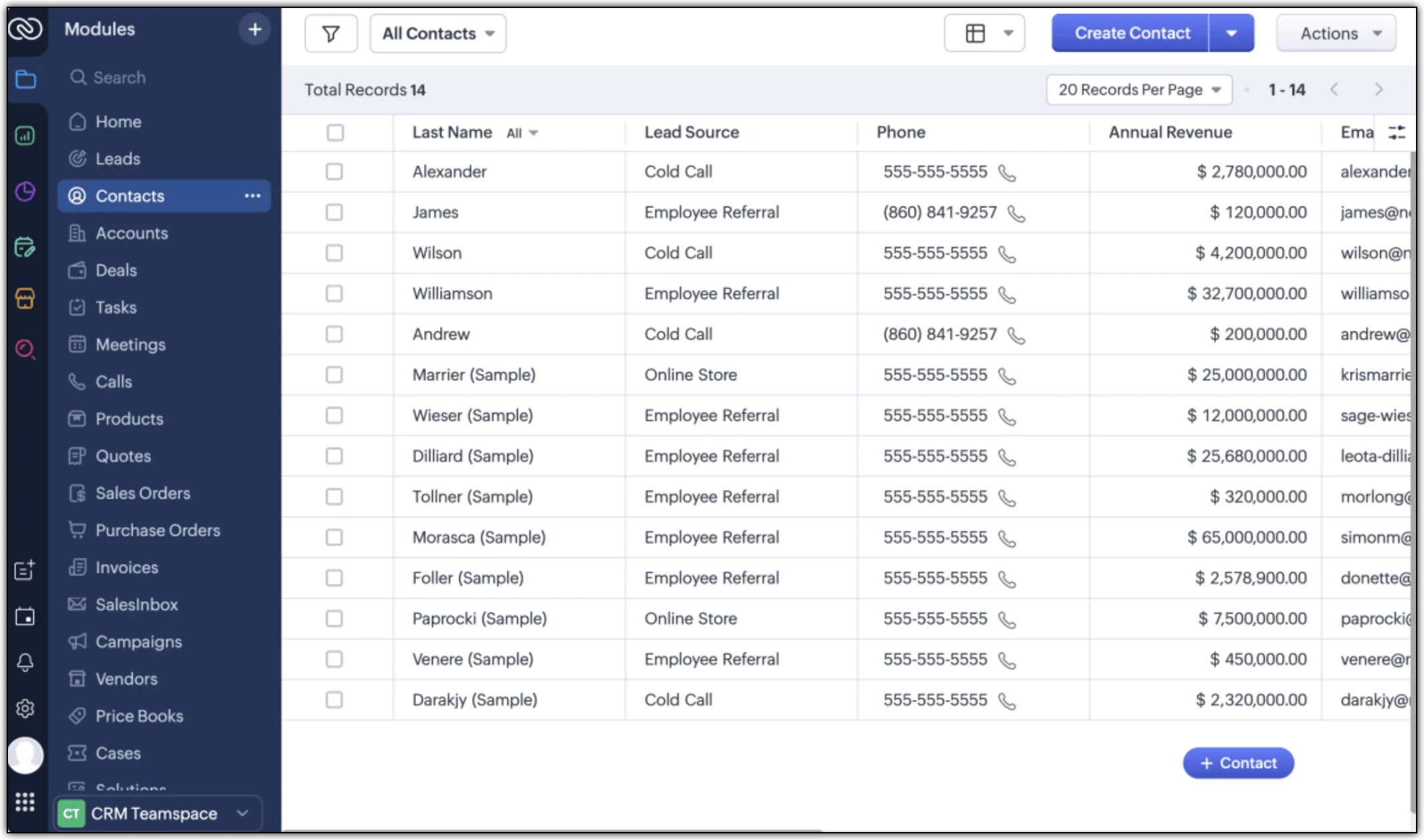

3. Zoho CRM - Best for Cost-Conscious Integration

Pricing: $12-$45/user/month with annual billing discounts

Zoho CRM delivers exceptional value through integration with Zoho’s business suite, particularly Zoho Inventory and Zoho Books. This connectivity creates seamless data flow from customer inquiry to production planning.

Key differentiators:

- Native inventory integration: Real-time product availability during quote generation

- Affordable automation: Advanced workflows and email sequences at entry-level pricing

- Zia AI assistant: Trend analysis and sales forecasting specifically tuned for manufacturing patterns

- Multi-channel communication: Unified inbox for email, phone, live chat, and social media interactions

Best for: Budget-conscious manufacturers needing CRM-inventory integration without enterprise-level complexity or cost.

Integration advantage: Zoho’s unified platform eliminates data silos between sales, inventory, and accounting functions.

Manufacturing CRM Implementation Strategy

Week 1-2: Data Foundation

- Import existing customer data with complete contact hierarchies

- Map decision-maker roles and influence levels for top 20% of accounts

- Establish lead sources and attribution tracking

Week 3-4: Process Configuration

- Configure sales stages aligned with manufacturing quote-to-delivery process

- Set up automated workflows for quote follow-ups and specification changes

- Create custom fields for technical requirements and compliance tracking

Week 5-8: Team Adoption

- Train sales team on opportunity management and activity logging

- Implement daily usage metrics and accountability measures

- Refine workflows based on initial user feedback

Success indicators: Target 90% user adoption within 60 days and 25% increase in qualified opportunities within the first quarter.

Integration Strategy & Selection Guide: Building Your Manufacturing Software Stack

The integration imperative: Analysis of 200+ manufacturing software implementations reveals that companies deploying systems sequentially achieve 40% better ROI than those attempting simultaneous multi-system rollouts. The key lies in establishing data foundation first, then layering operational capabilities strategically.

Critical insight: 73% of failed implementations stem from attempting to solve too many problems simultaneously rather than following a proven sequential approach. Smart manufacturers build their software stack incrementally, ensuring each system stabilizes before adding complexity.

The Proven Implementation Sequence

Phase 1: Inventory Foundation (Months 1-3) Start with ERP-focused inventory management to establish data accuracy and process discipline.

Required capabilities:

- Real-time stock tracking across all locations

- Automated reorder points based on consumption patterns

- Basic Bill of Materials with cost calculations

- Integration with existing accounting software

Success metrics: 95% inventory accuracy, 30% reduction in stockouts, elimination of manual spreadsheet tracking.

Phase 2: Production Control (Months 4-6) Add MES functionality once inventory data reliability reaches 95% accuracy.

Integration requirements:

- Automatic work order creation from ERP sales orders

- Real-time material consumption updates back to inventory

- Production scheduling synchronized with material availability

- Quality data feeding back to product cost calculations

Success metrics: 25% reduction in production lead times, 35% decrease in unplanned downtime.

Phase 3: Customer Intelligence (Months 7-9) Implement CRM after production processes stabilize and data flows reliably.

Integration touchpoints:

- Quote generation using real-time inventory and production capacity

- Opportunity tracking with delivery date accuracy

- Customer order history integration with production planning

- Service request tracking connected to production quality data

Software Compatibility Matrix

High Integration Priority Combinations:

- Controlata + HubSpot: Shared customer data, quote-to-production workflow

- Katana + Salesforce: Advanced production scheduling with sales forecasting

- NetSuite + Any MES: Comprehensive ERP backbone supporting shop floor systems

API Capability Assessment Framework:

- Bi-directional data sync: Can systems exchange data automatically?

- Real-time updates: Do changes propagate within 5 minutes?

- Error handling: Are failed transactions logged and retried?

- Custom field mapping: Can you sync unique business data requirements?

Total Cost of Ownership Calculator

Direct Costs (60% of TCO):

- Software licensing: Monthly/annual subscription fees

- Implementation services: Setup, training, and go-live support

- Hardware requirements: Servers, mobile devices, network infrastructure

Indirect Costs (40% of TCO):

- Internal labor: Employee time for training, testing, and process changes

- Productivity loss: Temporary efficiency reduction during transitions

- Ongoing maintenance: Updates, backups, and system administration

ROI Calculation Framework:

Monthly Savings = (Inventory carrying cost reduction) + (Labor efficiency gains) + (Production downtime reduction)

Implementation Investment = (Software costs) + (Services) + (Internal labor)

Payback Period = Implementation Investment ÷ Monthly Savings

Benchmark expectations: Well-executed implementations typically achieve 12-18 month payback periods with 20-35% operational efficiency improvements.

Change Management Critical Success Factors

Week 1-4: Foundation Building

- Designate internal champions for each department

- Document current processes before system changes

- Establish communication cadence with weekly progress updates

Week 5-12: Controlled Rollout

- Implement with 20% of users first (pilot group)

- Collect daily feedback and adjust workflows

- Measure adoption metrics: logins, data entry completion, process compliance

Week 13+: Full Deployment

- Scale to remaining users based on pilot learnings

- Implement ongoing training schedule for new features

- Establish performance dashboards for continuous improvement

Success formula: Companies with dedicated change management achieve 85% user adoption versus 45% for technology-only implementations.

Choosing Your Manufacturing Software Path: Next Steps and Recommendations

The strategic decision: Your software selection should align with your current operational maturity and 18-month growth trajectory, not aspirational end-state requirements. Companies that choose systems matching their actual needs achieve 60% faster implementation than those selecting overly complex solutions.

Recommended Software Combinations by Business Profile

Startup Manufacturers (5-15 employees, < $2M revenue):

- Primary recommendation: Controlata (Starter or Business tier) + HubSpot CRM (Free tier)

- Investment: $0-$100/month total

- Focus: Establish inventory accuracy and basic customer tracking

Growing Small Manufacturers (15-50 employees, $2-10M revenue):

- Primary recommendation: Controlata (Professional tier) + Plex MES + Zoho CRM

- Investment: $400-700/month total

- Focus: Integrate production control with inventory and customer management

Scaling Manufacturers (50+ employees, $10M+ revenue):

- Primary recommendation: NetSuite + Tulip MES + Salesforce Manufacturing Cloud

- Investment: $2,000-5,000/month depending on user count

- Focus: Enterprise-grade capabilities supporting complex operations and growth

Your Implementation Roadmap

Months 1-2: Foundation Assessment

- Audit current systems and establish baseline metrics

- Request demos from top 2 ERP solutions in your category

- Secure budget approval for 18-month implementation plan

Months 3-4: ERP Implementation

- Deploy inventory management system first

- Achieve 95% inventory accuracy before proceeding

- Train team and establish data discipline

Months 5-9: Sequential System Addition

- Add MES capabilities once inventory stabilizes

- Integrate CRM after production processes are reliable

- Focus on data flow between systems, not customization

Critical Success Factors

Start with data foundation: 95% inventory accuracy is prerequisite for successful MES or advanced CRM implementation.

Sequential implementation wins: Companies following the ERP → MES → CRM sequence achieve 40% better ROI than simultaneous deployments.

Ready to begin? Explore Controlata’s features and see how real-time tracking can transform your production efficiency.