Manufacturing Cost Calculation

Controlata is a modern manufacturing cost management software that automatically calculates the cost of each product unit and entire production order, accounting for all expenses. Analyze your cost structure and optimize your production efficiency with real-time insights into your manufacturing costs.

Essential Cost Control Features

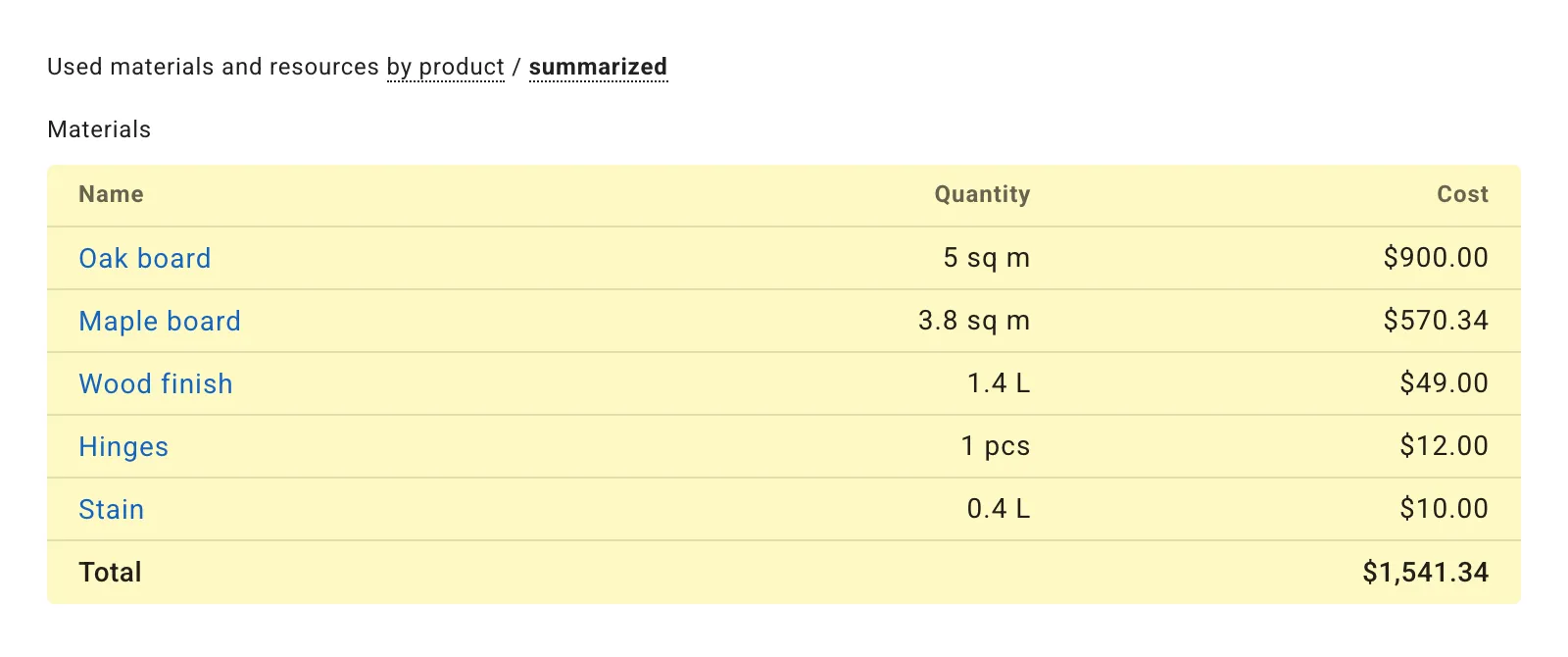

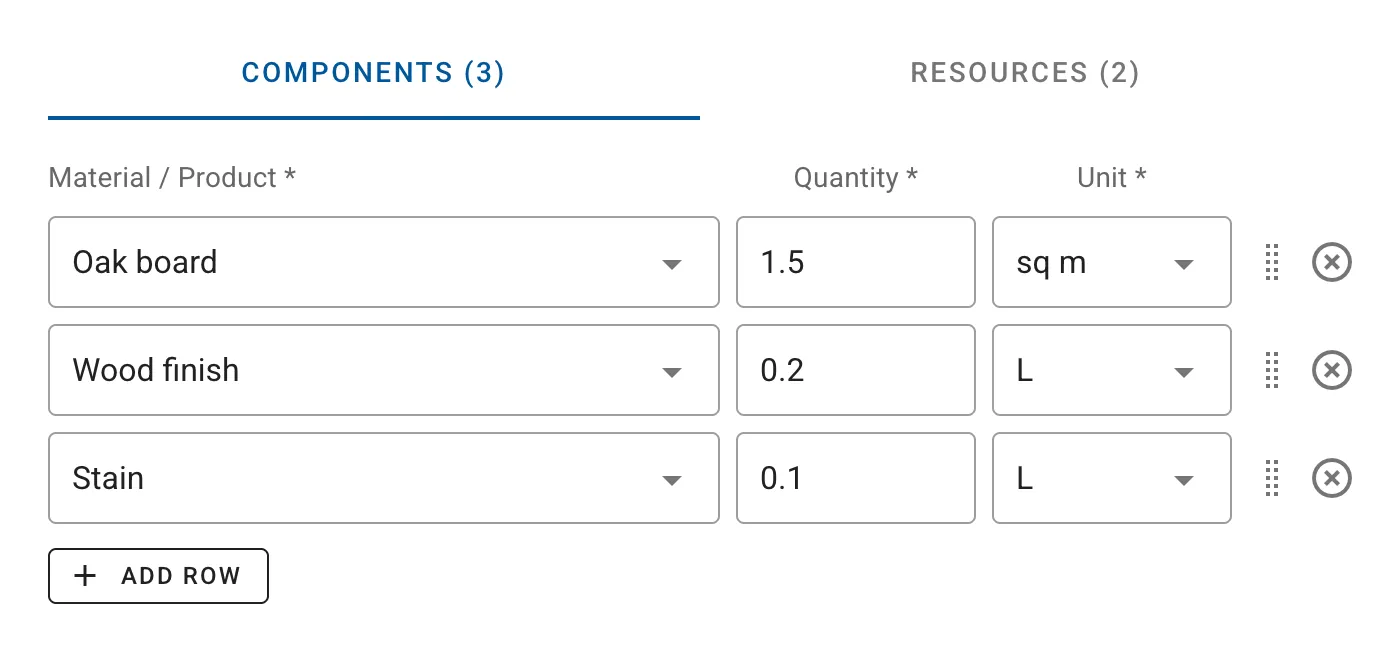

Real-time Material Cost Tracking

Track raw material costs with precision in your manufacturing process. Our system automatically calculates material consumption based on your bill of materials and uses the FIFO method for accurate cost assessment, ensuring complete visibility of your material expenses.

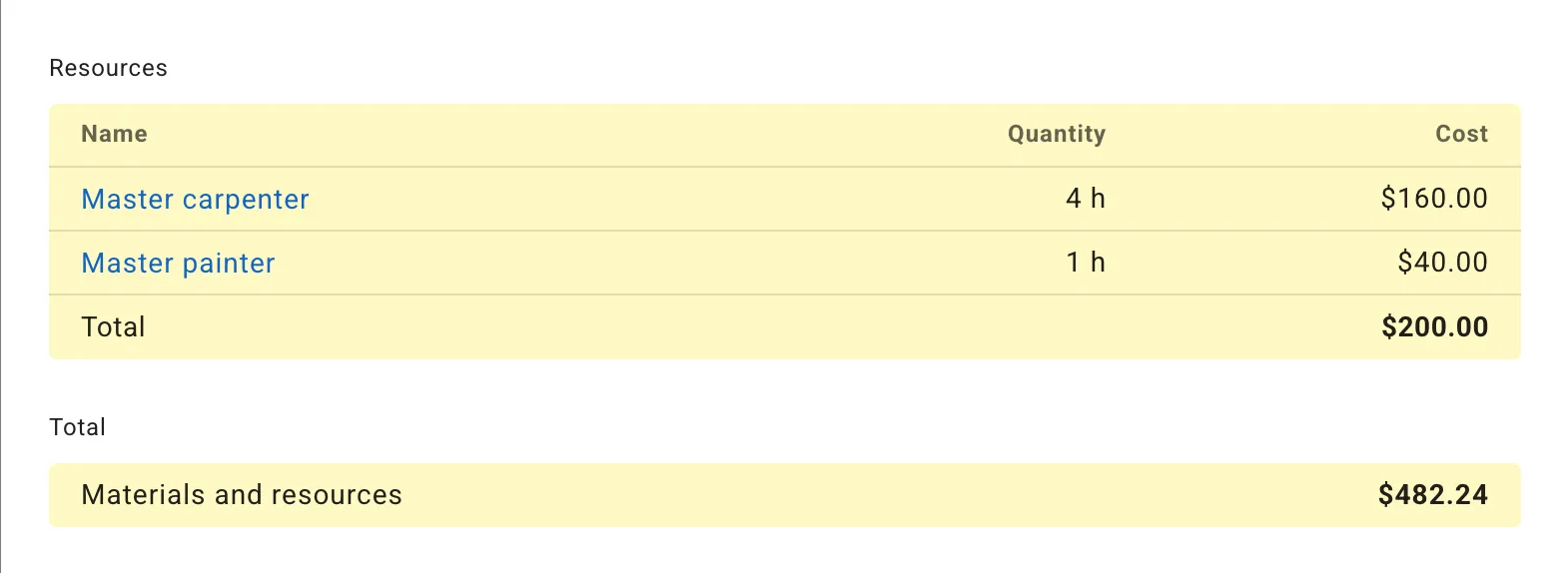

Production Labor Cost Management

Optimize workforce costs by tracking production labor expenses in real-time. Define employee rates and operation times in your bill of materials, and let the system automatically calculate labor costs for each production run, providing accurate insights into your workforce expenses.

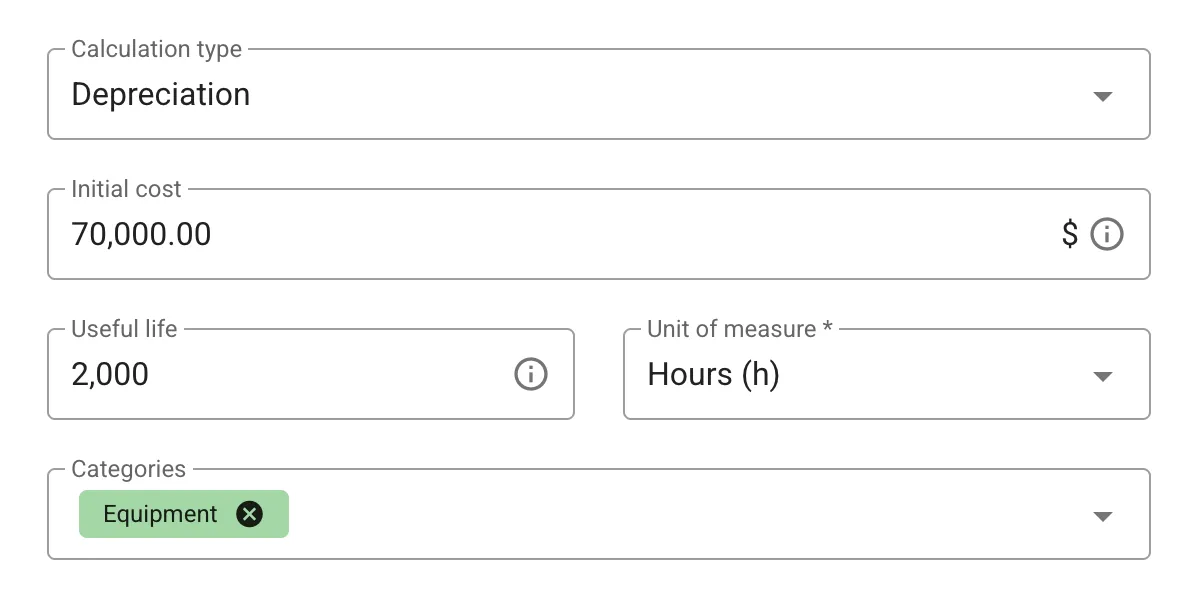

Equipment Cost Management

Monitor equipment costs effectively by tracking depreciation rates and usage time. Input equipment values, lifecycle data, and operational hours in your bill of materials for automated calculation of equipment-related manufacturing costs.

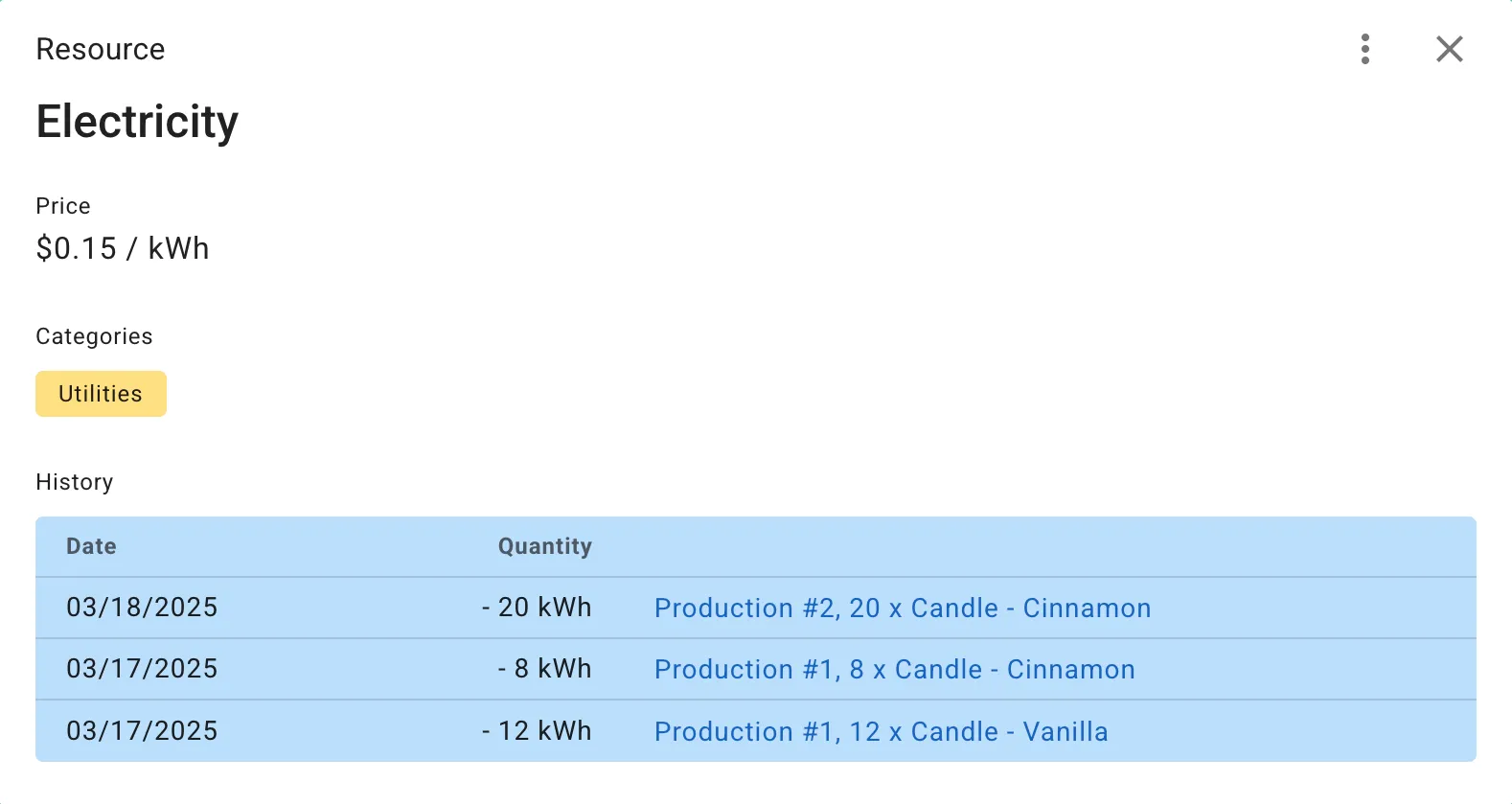

Comprehensive Cost Control

Track all additional manufacturing expenses, from utilities to overhead costs. Integrate every cost component into your bill of materials for a complete understanding of your total production expenses and maintain accurate cost calculations.

Real-time Batch Cost Analysis

Get instant insights into your production batch costs upon completion. Our system automatically calculates actual costs using FIFO method for materials, while tracking real labor and overhead expenses based on your bill of materials.

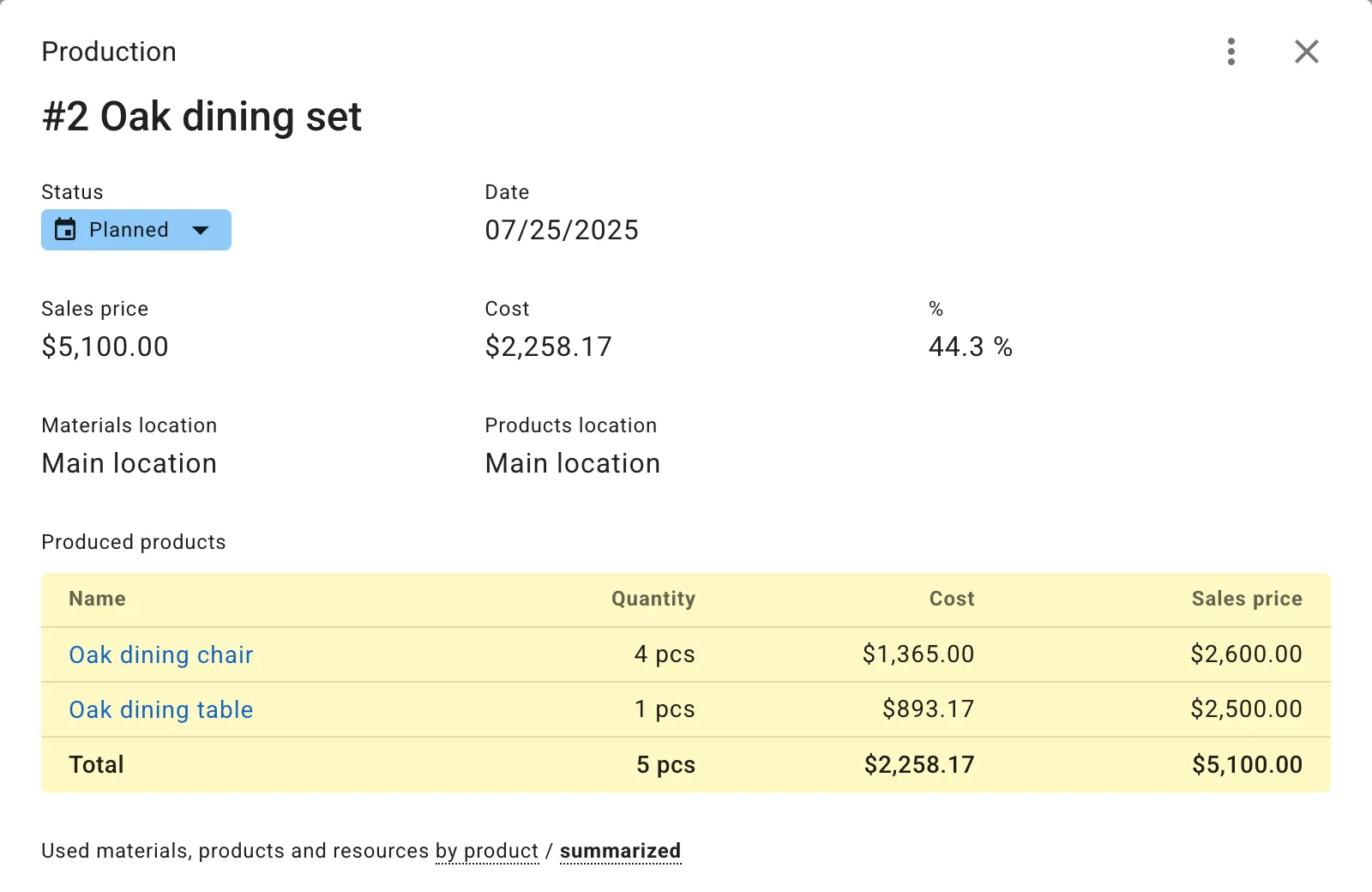

Production Planning Cost Analysis

Make informed decisions before production begins with accurate cost forecasting. Calculate estimated production costs using current material prices and standardized expenses from your bill of materials to optimize your manufacturing strategy.

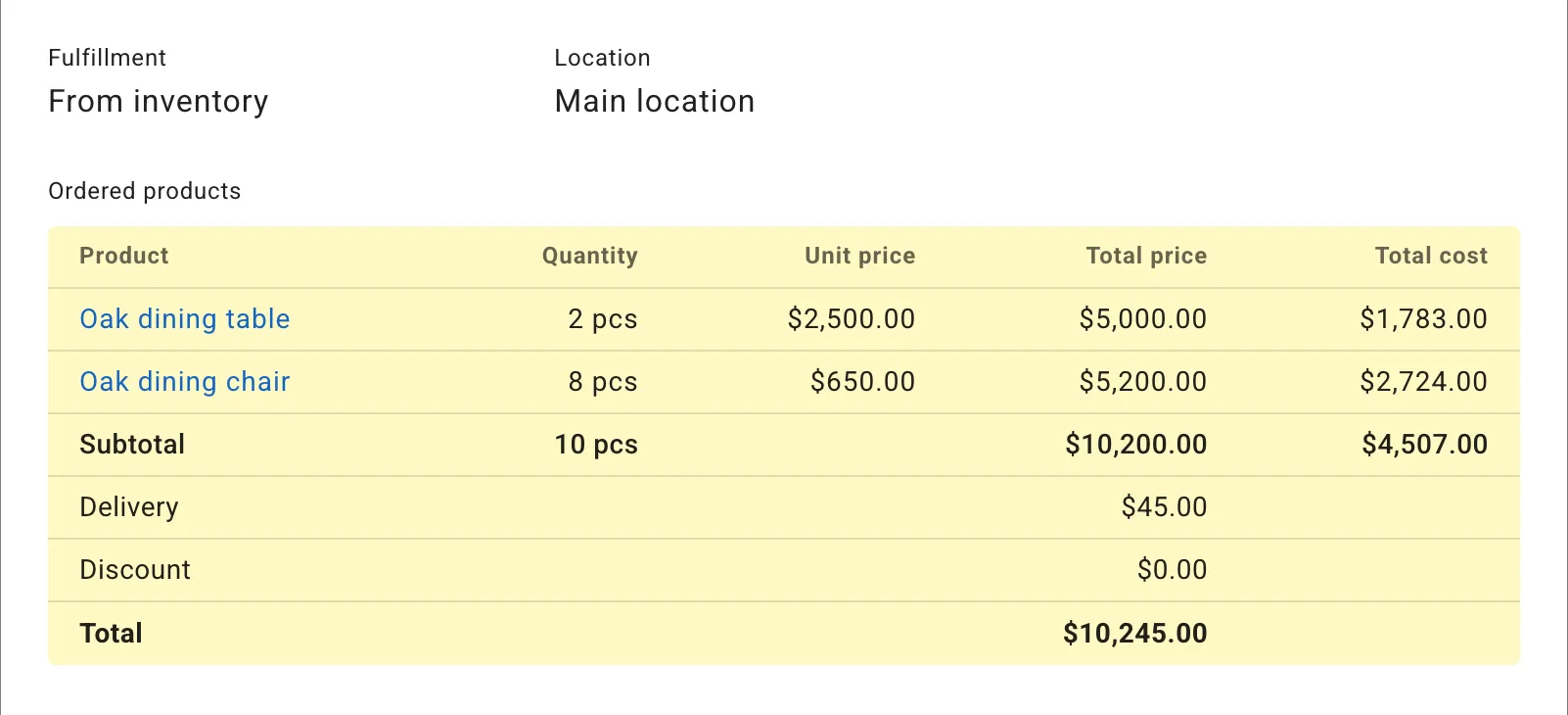

Order Cost Intelligence

Access detailed cost analysis for each customer order to optimize your pricing strategy. Track actual production costs in real-time to maintain healthy profit margins and make data-driven decisions about pricing and discounts.

Unlock Better Cost Management

Precise Cost Calculation

Achieve maximum accuracy in batch cost calculations through real-time inventory tracking and FIFO method implementation, ensuring reliable cost data for every production run.

Comprehensive Cost Tracking

Track both direct material costs and overhead expenses in one unified system. Our solution ensures no cost component is overlooked in your manufacturing process.

Streamlined Efficiency

Eliminate manual calculations in spreadsheets. Get automated cost calculations instantly upon production batch completion, saving valuable time and reducing human error.

Enhanced Management Insights

Gain clear visibility into actual costs for each production order, enabling accurate profit tracking across your product range through detailed management reporting.

Data-Driven Decision Making

Make informed decisions about pricing strategies, product mix, and cost optimization based on accurate, real-time manufacturing cost data.

Seamless Integration

Connect cost calculation with inventory management, orders, purchasing, and production modules for consistent, reliable data across your entire manufacturing operation.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.