Features

Controlata provides all essential tools for production planning and inventory management

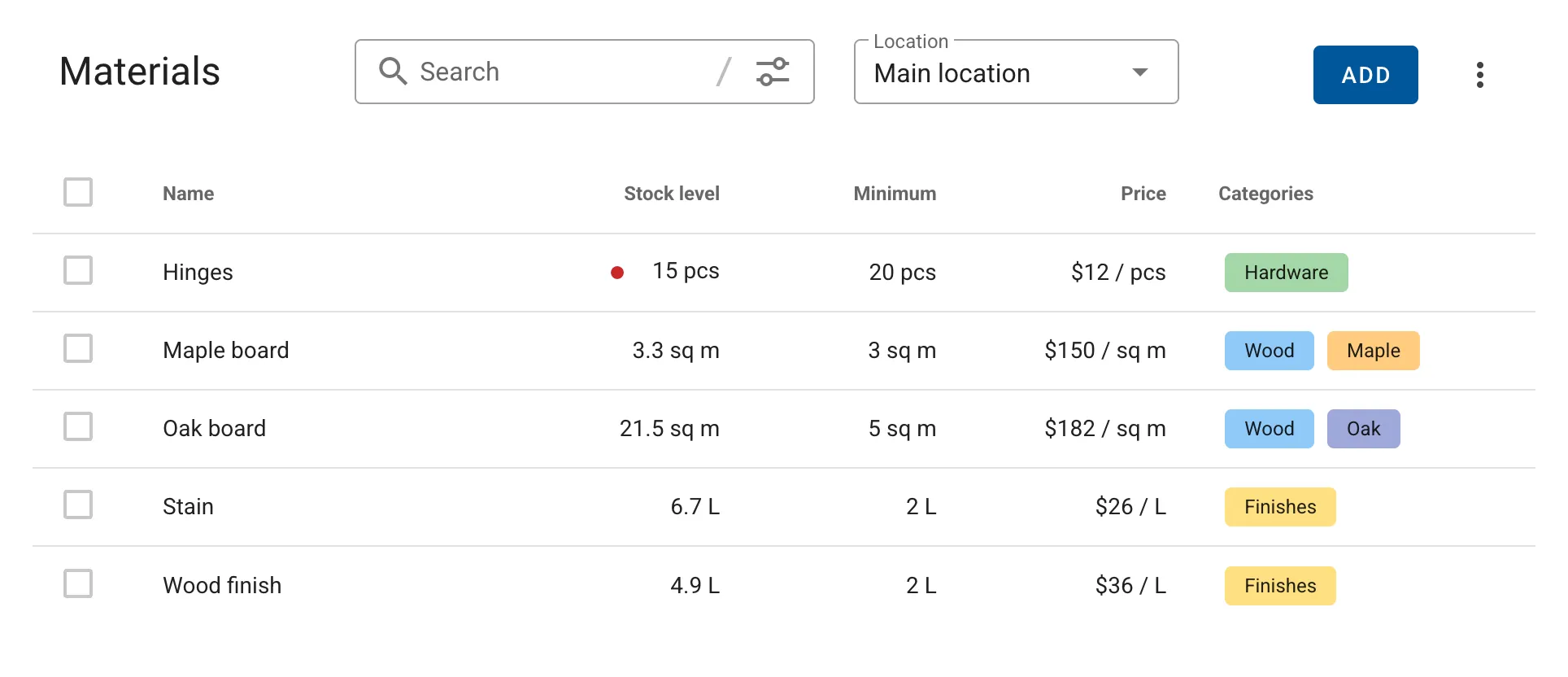

Real-time Inventory

Monitor your material stock levels in real-time through Controlata's cloud platform. Access your inventory data anytime from your computer, tablet, or phone.

The system maintains accurate stock levels by automatically tracking material movements during production. As you manufacture products, used materials are deducted from your inventory.

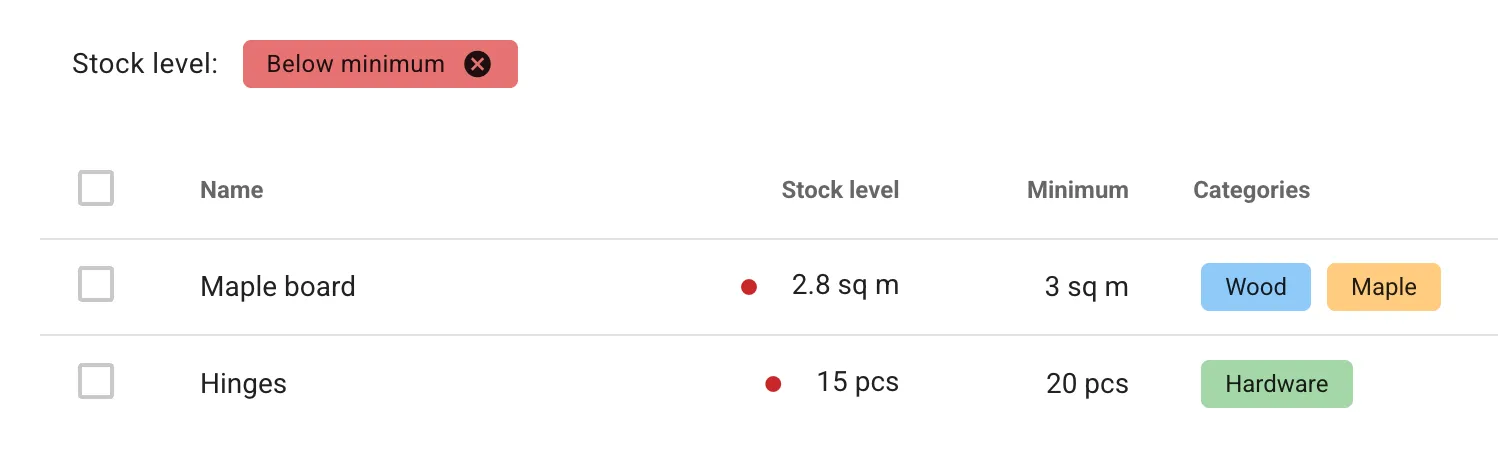

Low Stock Alerts

Define minimum stock thresholds for each material to maintain optimal inventory levels.

Receive timely alerts when materials drop below your set minimums. Before starting production, verify material availability to ensure your stock stays above critical levels.

Low stock notifications help you time your reorders perfectly and prevent stockouts.

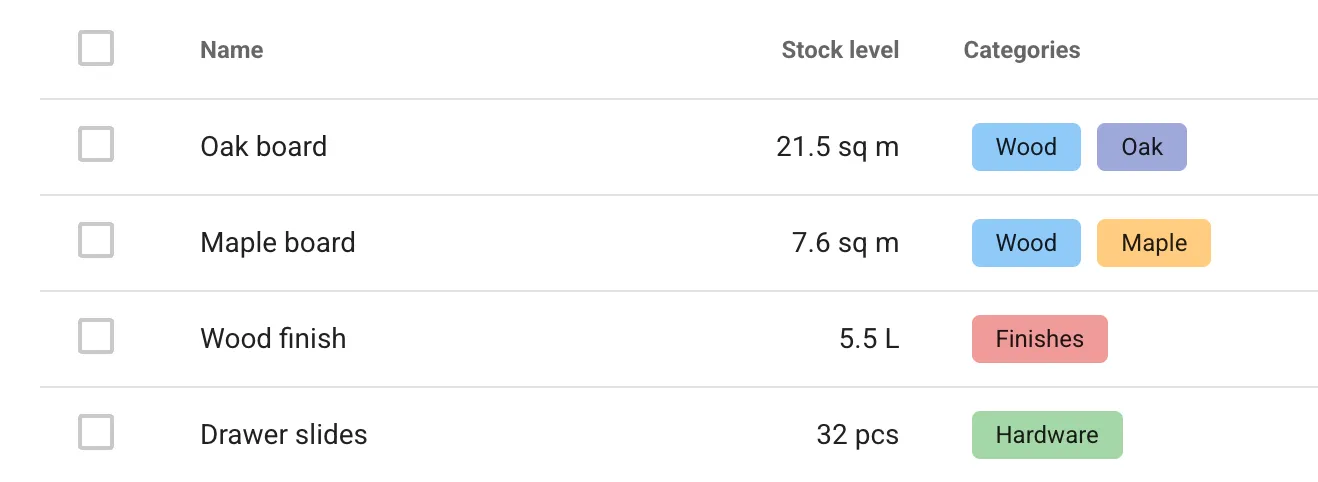

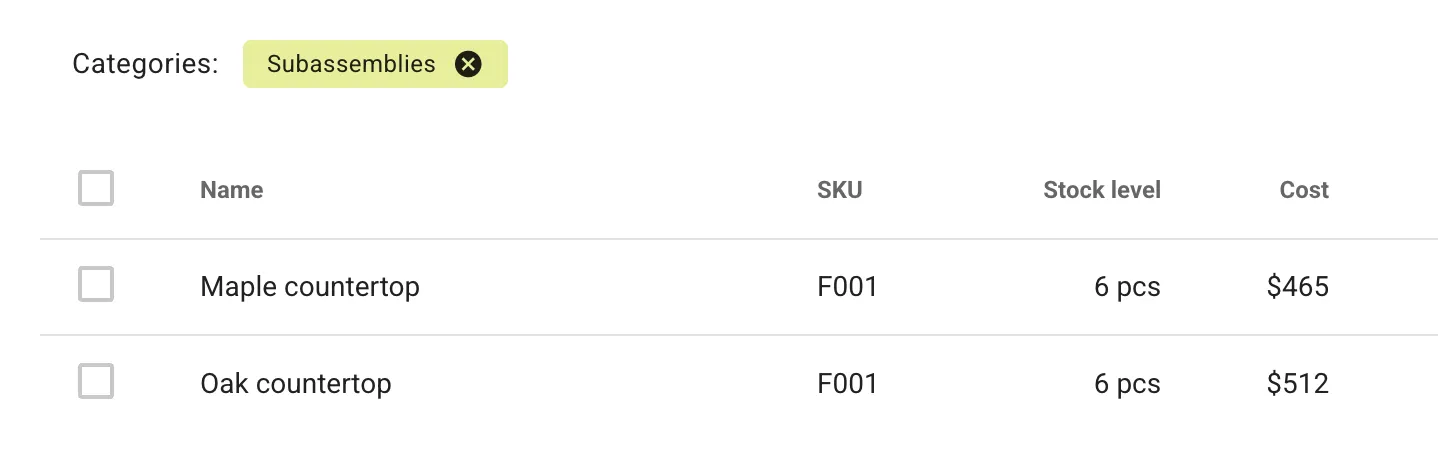

Category Management

Keep your inventory organized by grouping materials and products into customizable categories. Materials can belong to multiple categories for flexible organization.

Navigate your inventory effortlessly by filtering items through category tags with a single click.

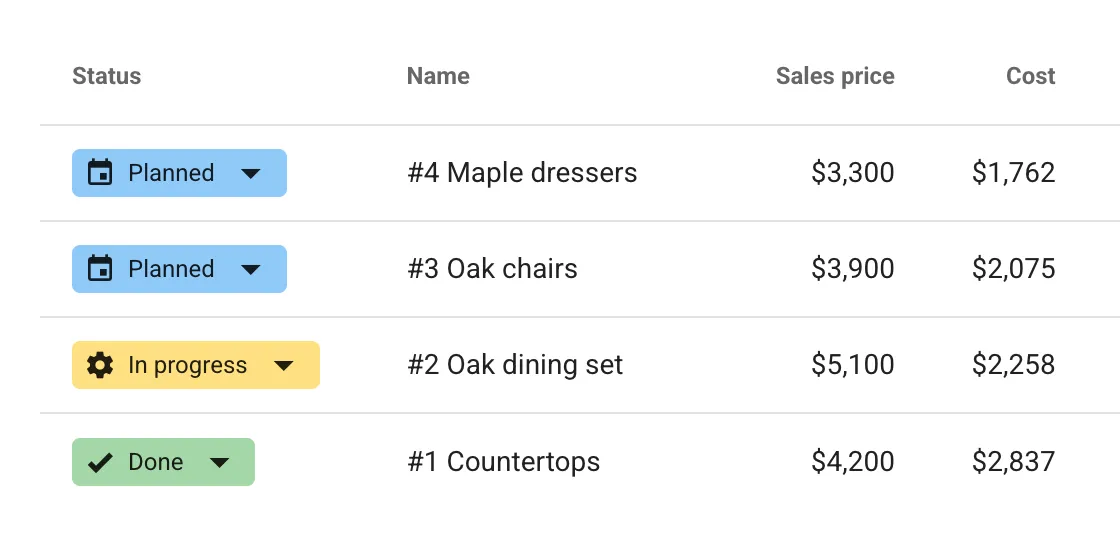

Production Planning

Track your manufacturing process with our intuitive production planning system. Each production batch moves through clearly defined stages:

- Planned

- In Progress

- Done

The system automatically deducts materials when production starts.

Once marked as completed, finished products are added to your inventory count.

Production Statuses

Replace the default statuses with your own. Create custom production statuses to match your production process. Set up any number of statuses and track the progress of each order through the production cycle.

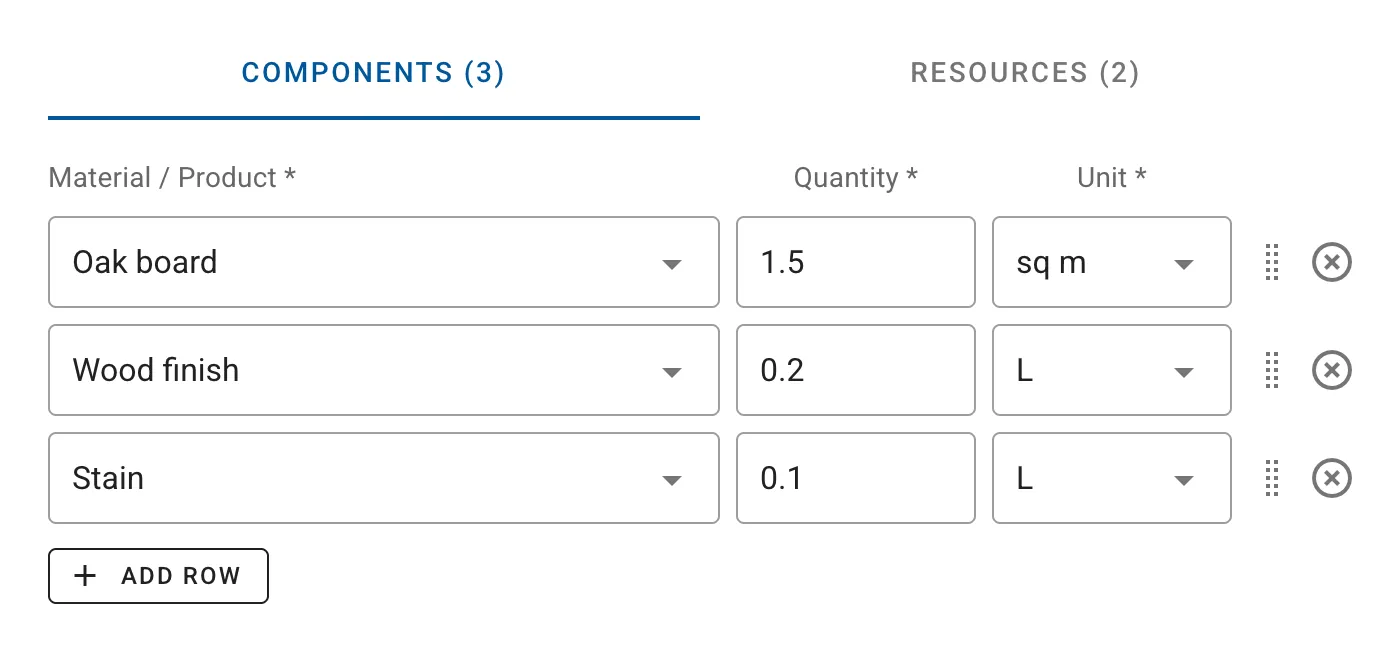

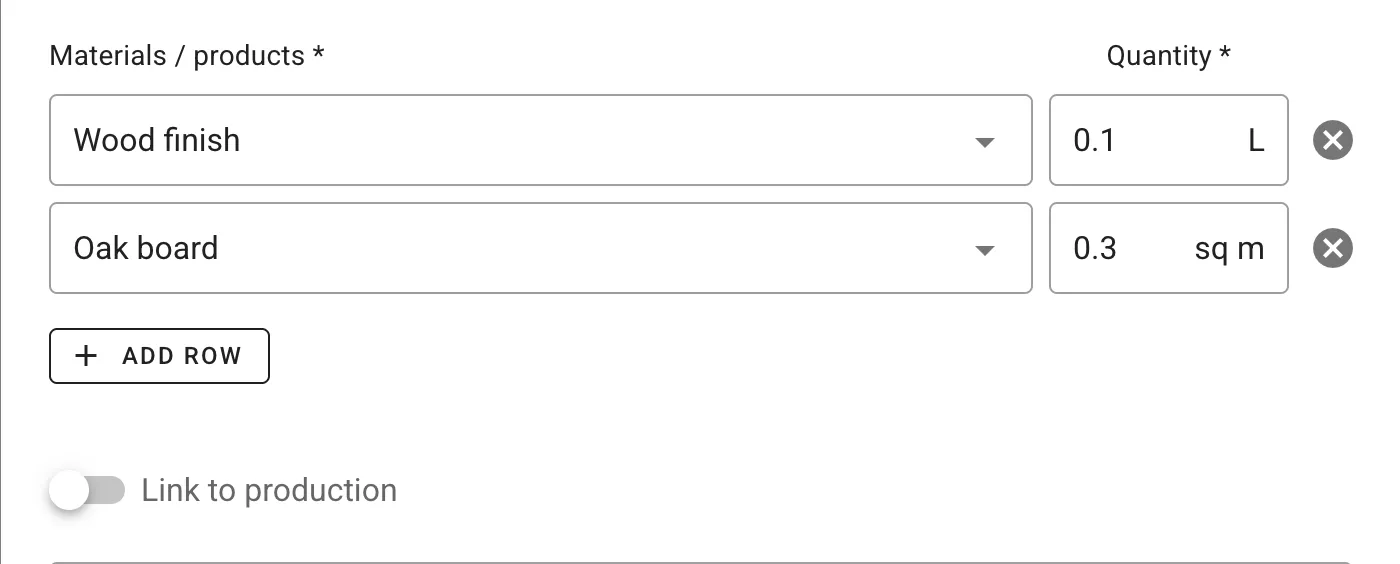

Bill of Materials

Create detailed product specifications by including all production components in your bill of materials:

- Raw materials and components

- Production operations

- Equipment depreciation

- Utility expenses

These specifications drive accurate product costing and automated material tracking during production.

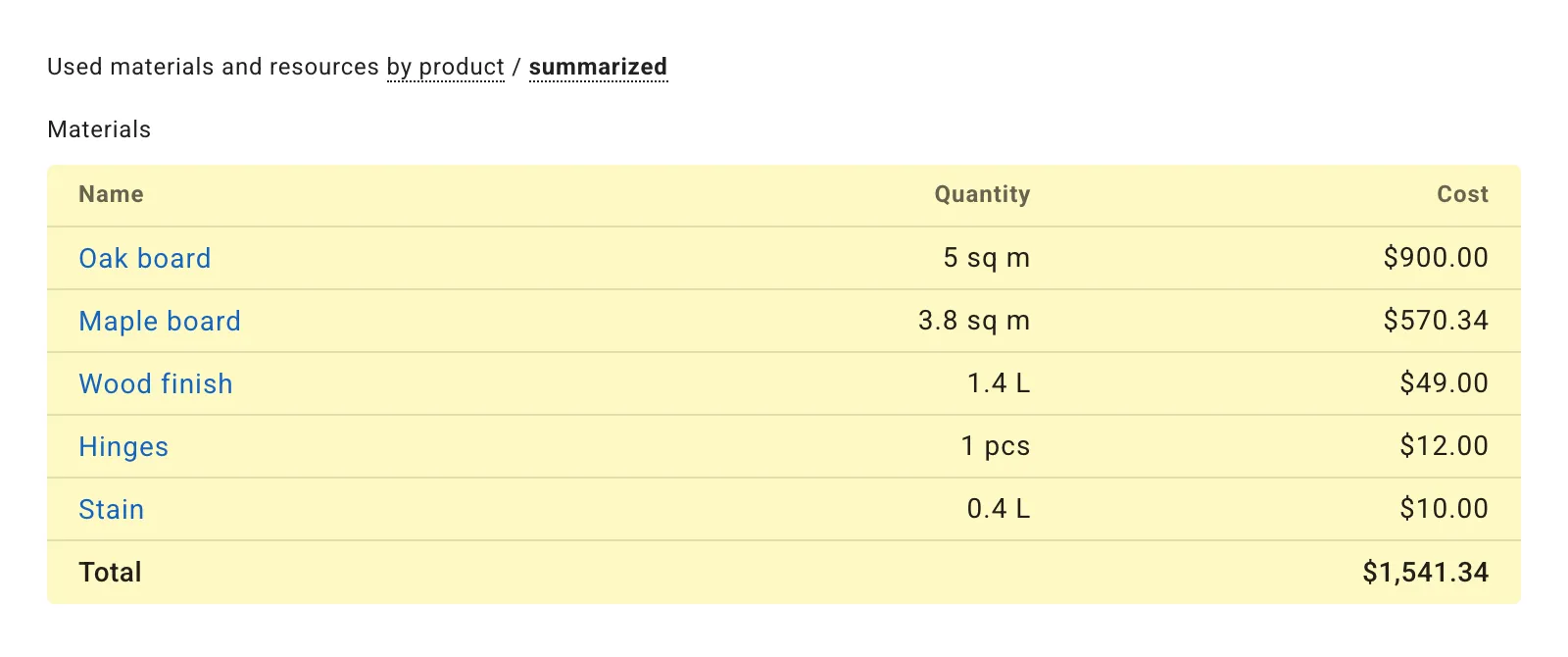

Product Cost Calculation

Controlata calculates production costs based on your bills of materials, giving you accurate insights into your product margins.

Track all cost components including materials, labor costs, utility expenses, and equipment depreciation to understand your true production costs.

See the cost breakdown and profitability for each customer order, helping you make informed pricing decisions.

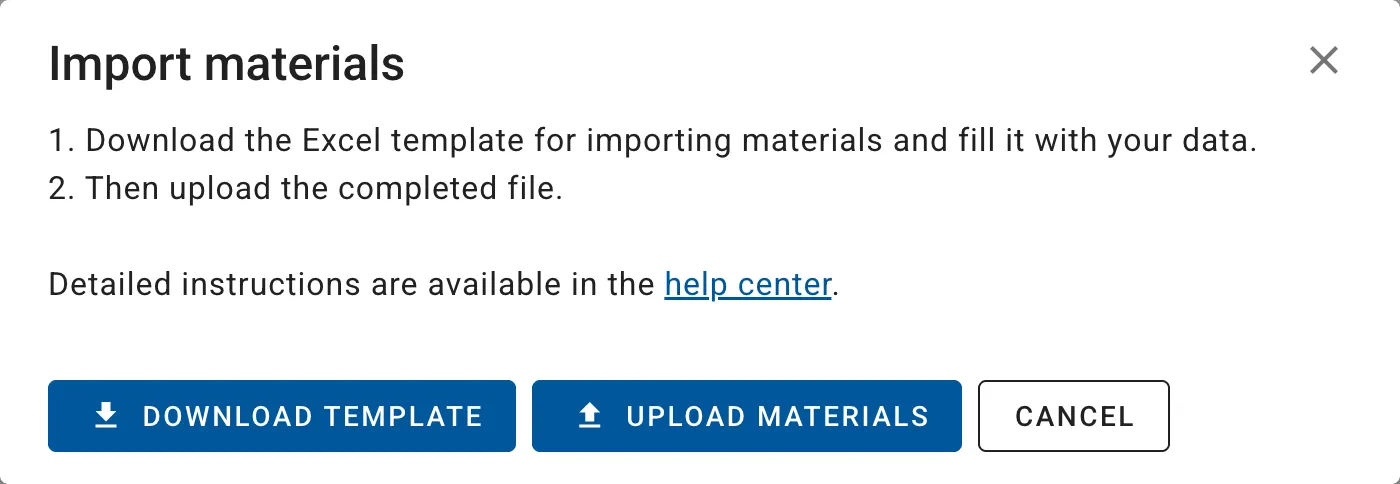

Material and Product Import

Already have your material and product database in another system? Quickly import your existing data into Controlata.

Simply prepare a CSV file with your data, and we'll help you transfer everything smoothly.

Our support team is ready to assist if you encounter any issues during the import process.

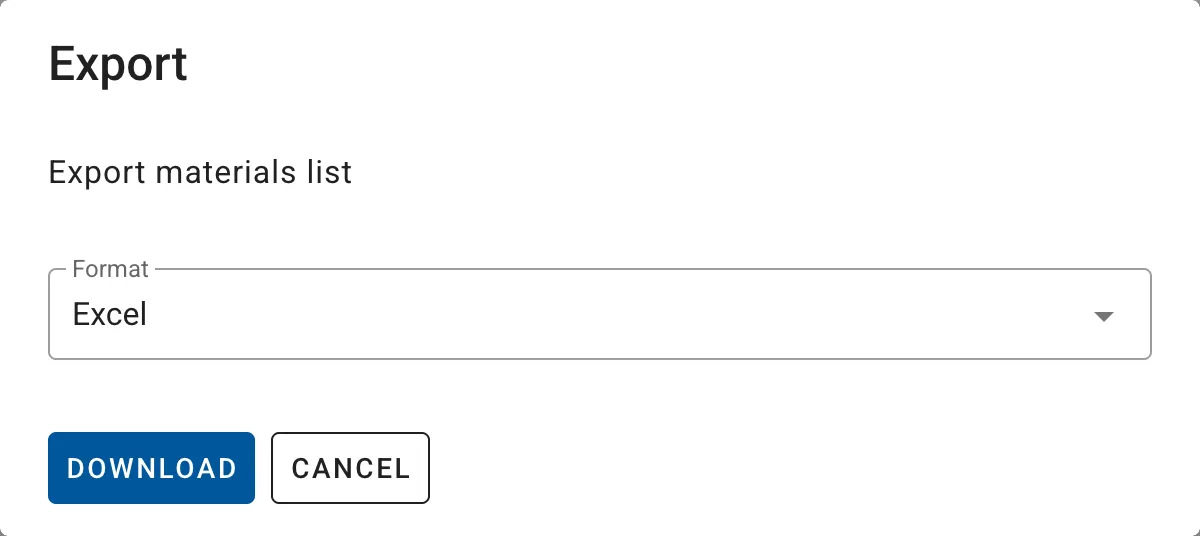

Data Export

Export your material and product lists from Controlata to CSV or XLS files whenever needed.

All other data is exportable too - including purchases, orders, production records, and more.

Your data belongs to you and is always accessible.

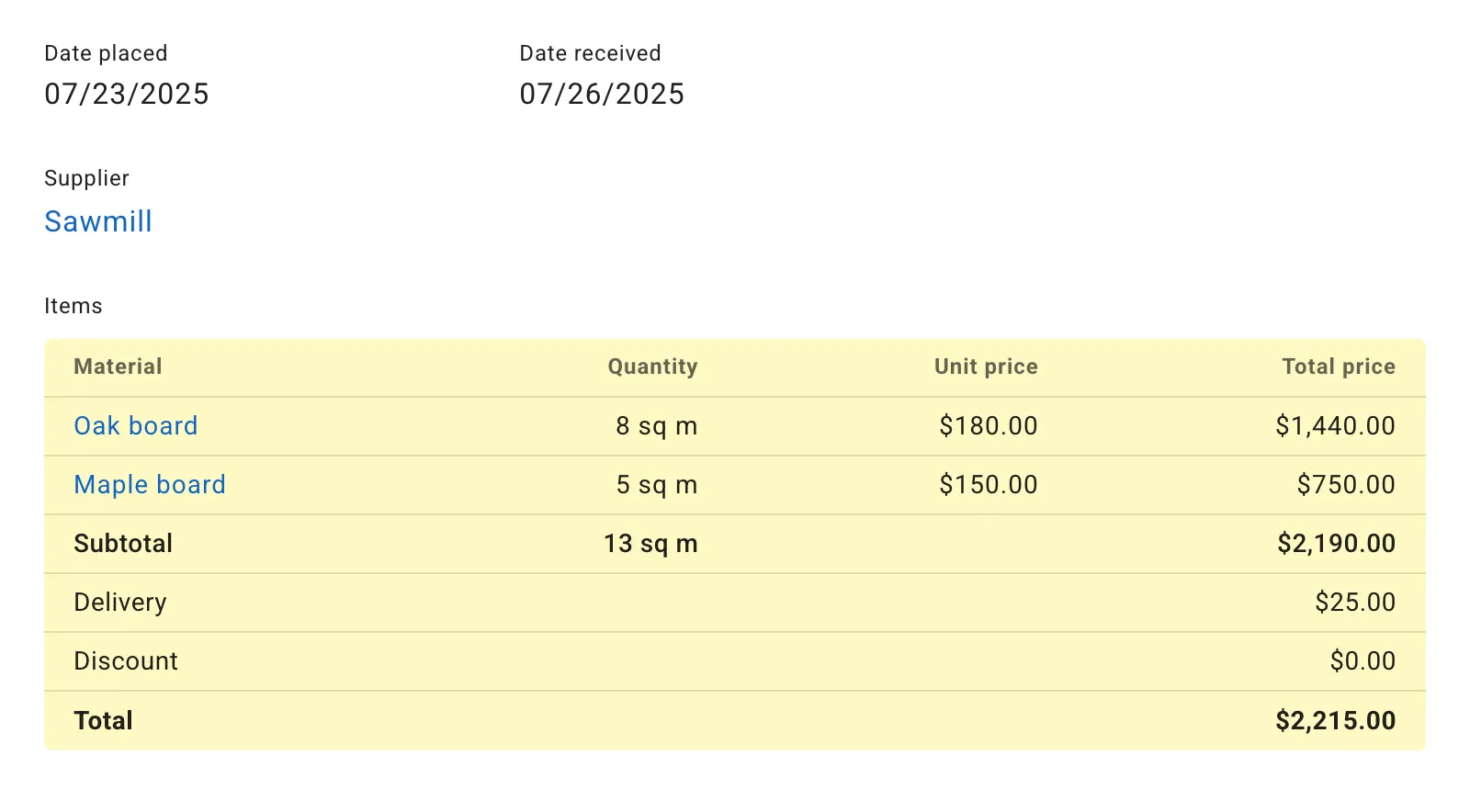

Purchase Orders

Track incoming material deliveries in Controlata. Purchase prices are automatically included in your product cost calculations.

Add shipping costs and discounts to ensure precise cost tracking. Maintain a supplier database to monitor order volumes and total spending with each vendor.

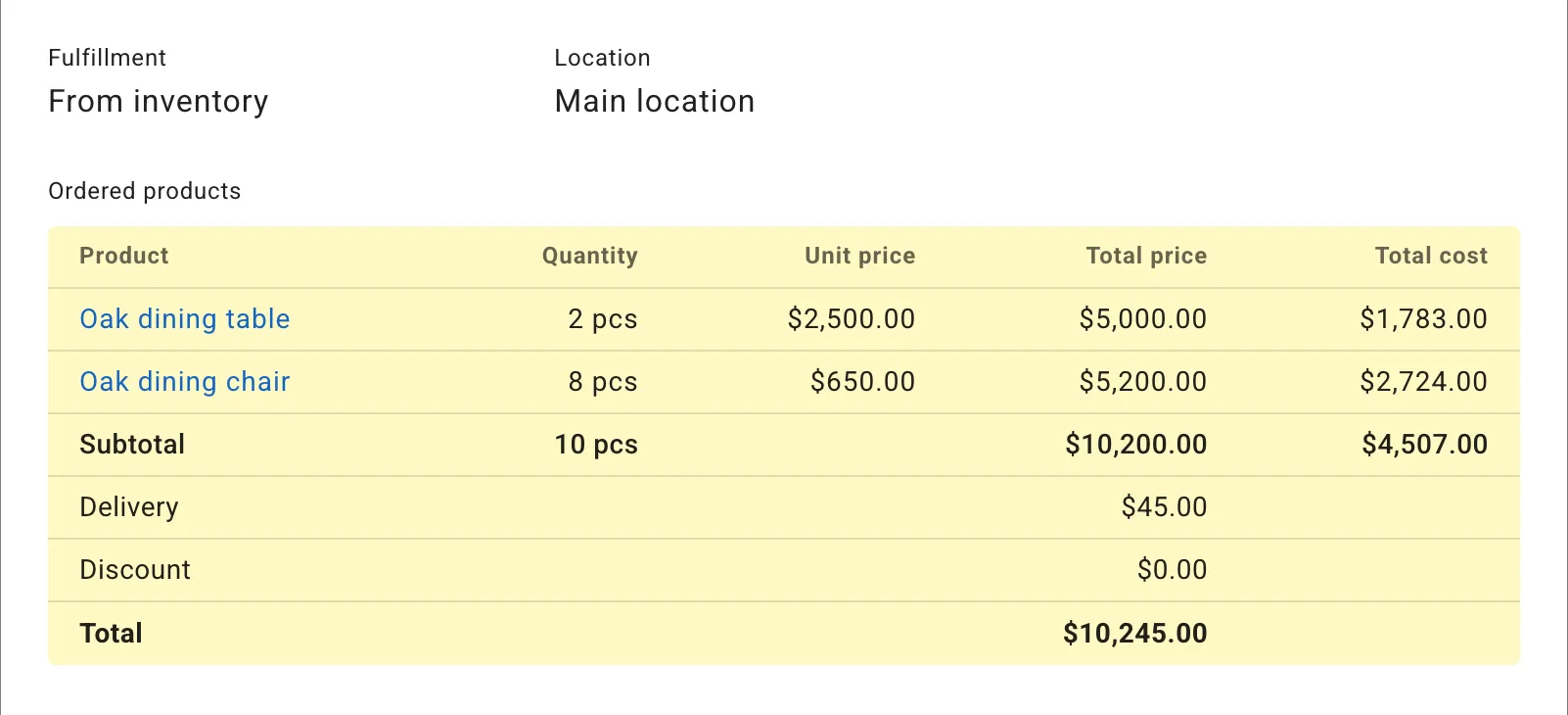

Sales Orders

Record customer orders in Controlata and instantly see the cost breakdown of products being sold.

Build a customer database to track order history and analyze total sales by customer.

Generate invoices directly from each order or print order details for internal use.

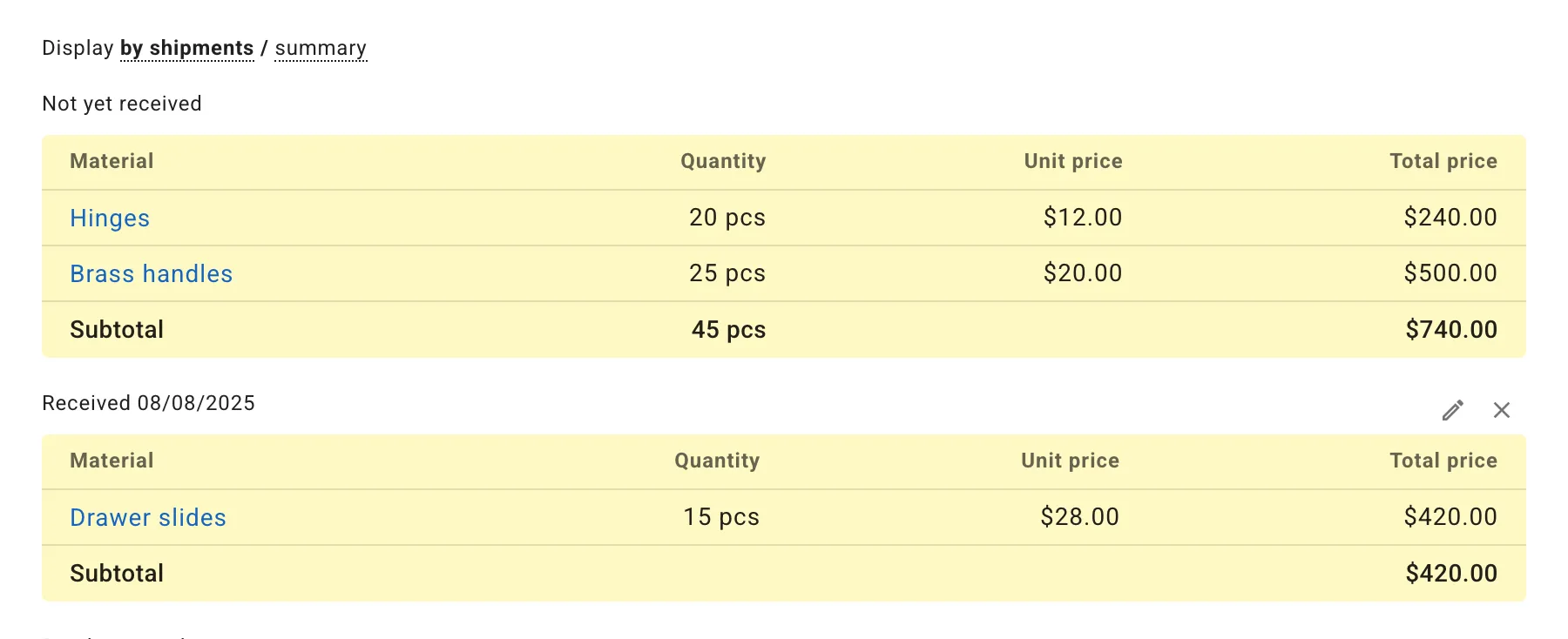

Partial Shipments

Create partial shipments for purchase and sales orders.

Split purchase and sales orders into multiple shipments when you need to fulfill orders gradually or when suppliers deliver materials in separate batches over time.

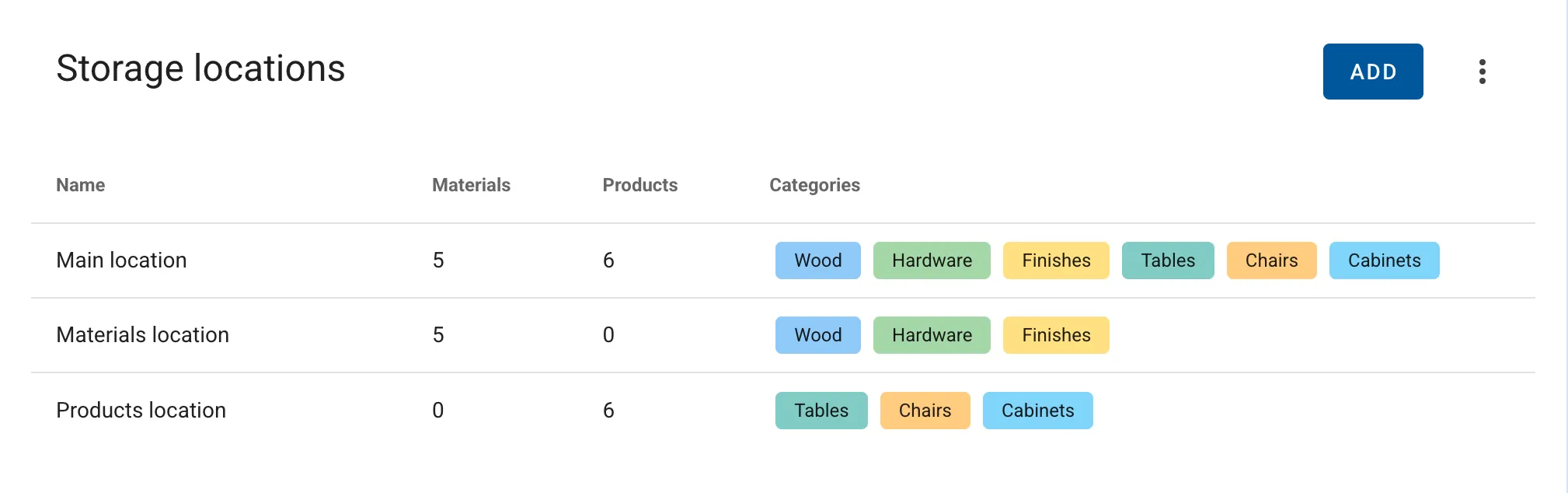

Storage Locations

Manage inventory across multiple storage locations with separate tracking for each warehouse.

Customize storage settings for materials and products at each location to match your warehouse organization.

Transfer materials and products between locations while maintaining accurate stock counts.

Write-offs

Keep track of damaged materials and defective products in the system.

Include write-off costs in your product costing calculations when needed for accurate margin analysis.

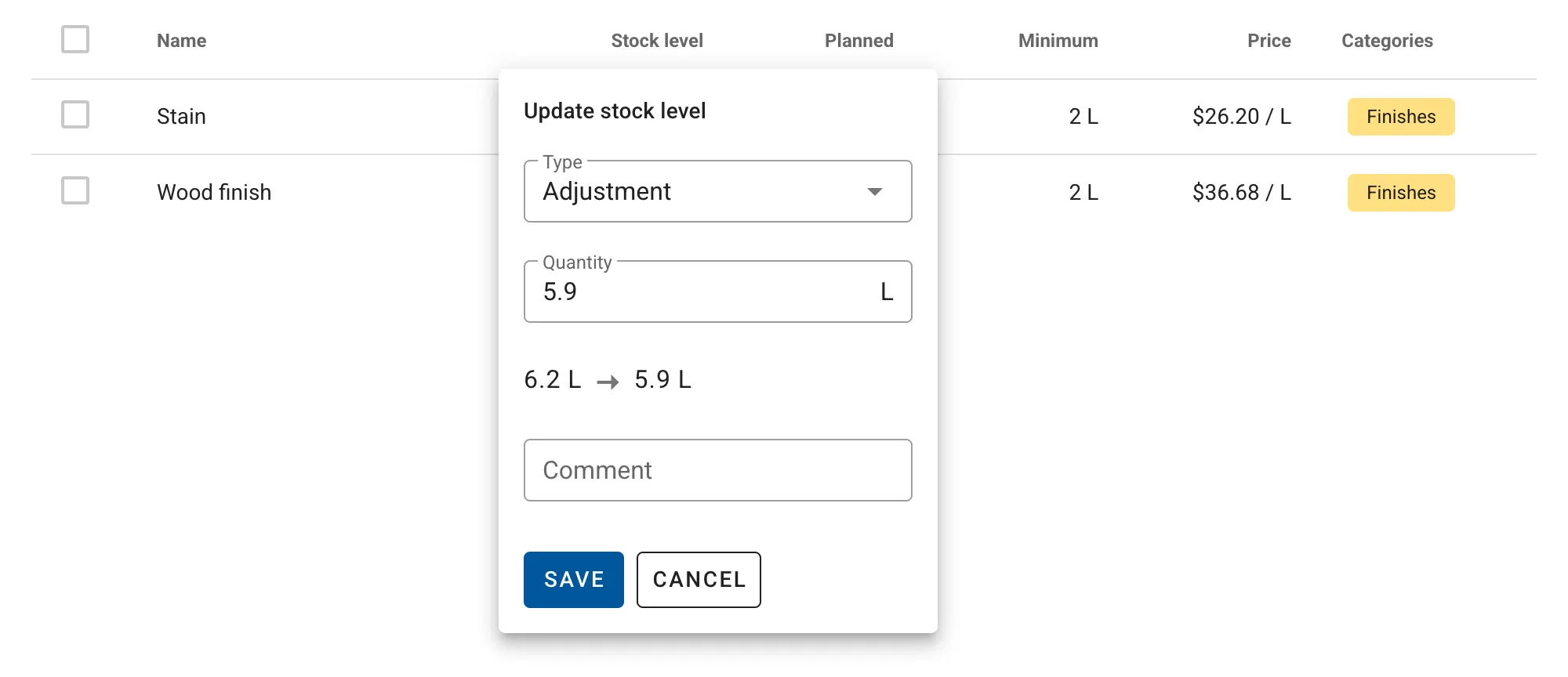

Quick Stock Updates

Update material or product quantities in just two clicks - no need to open detailed item cards.

Need a quick stock adjustment? Simply click the quantity and enter the new value. Add a comment if needed for your records.

All adjustments are logged in the item history, giving you full visibility of inventory movements.

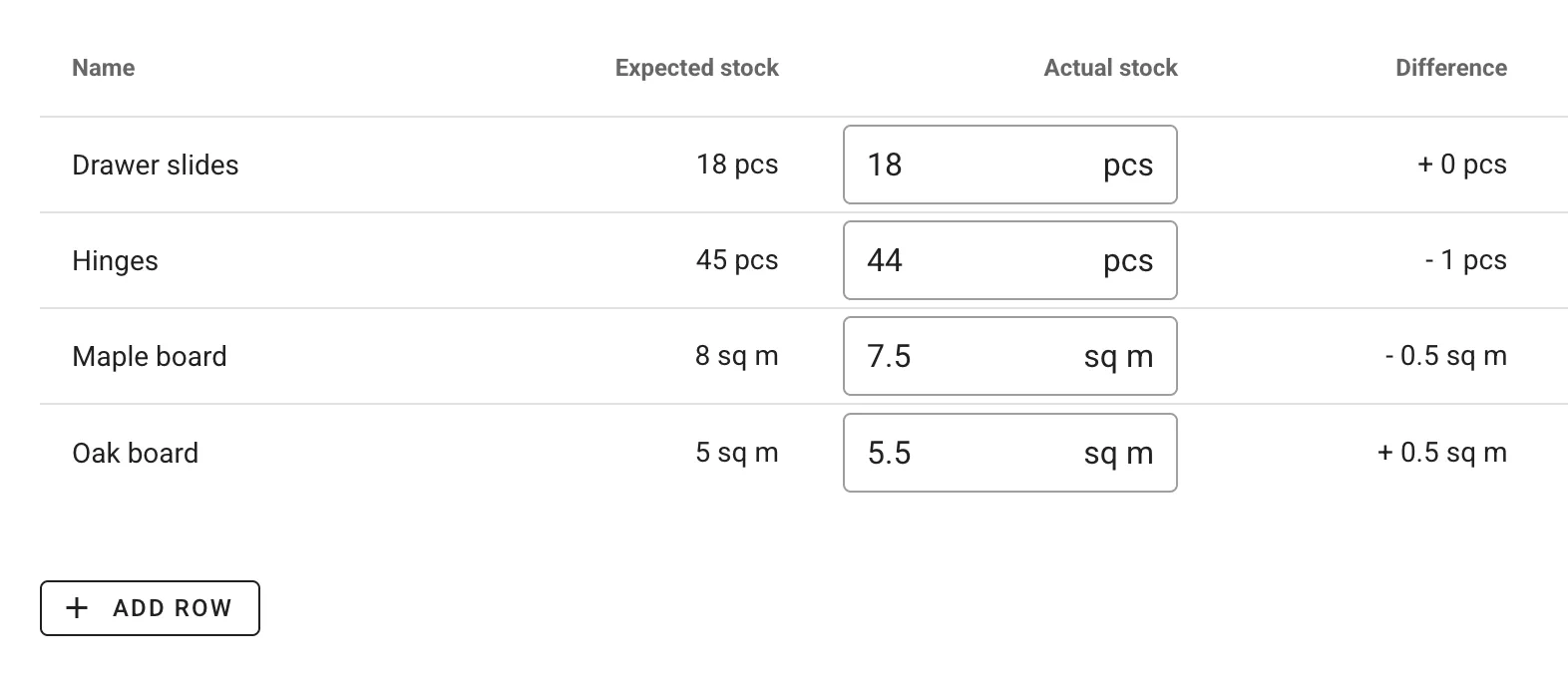

Inventory Audits

Compare your physical stock against system records using Controlata's inventory audits feature.

Choose which storage location to audit and which materials or products to include. Enter your physical counts and let the system calculate the differences.

The system will update stock levels and calculate audit results - surpluses and shortages.

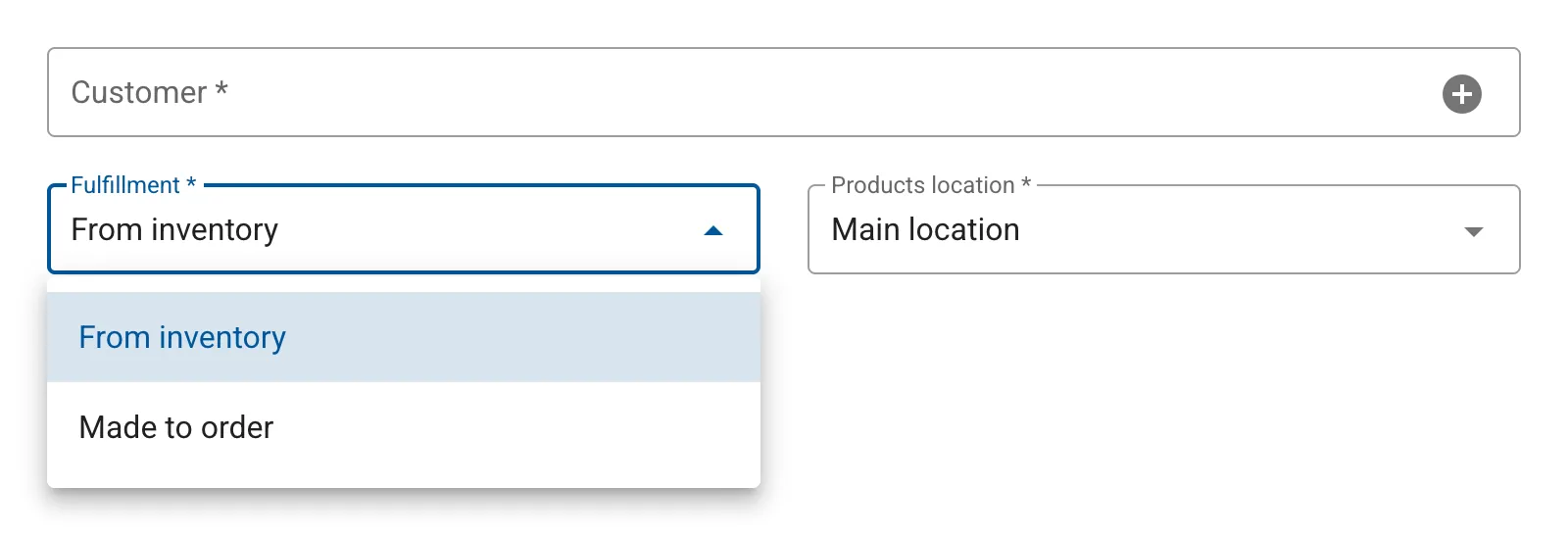

Make-to-Stock or Make-to-Order

Whether you manufacture products in advance or produce specifically for customer orders, Controlata adapts to your workflow.

When creating a sales order, choose to fulfill it from available stock or create a new production order specifically for this sale.

Subassemblies

For multi-stage manufacturing processes, create subassemblies that can be used as components in multiple finished products.

For example, if you manufacture furniture, you can create a 'Chair Base' subassembly and use it across different chair models.

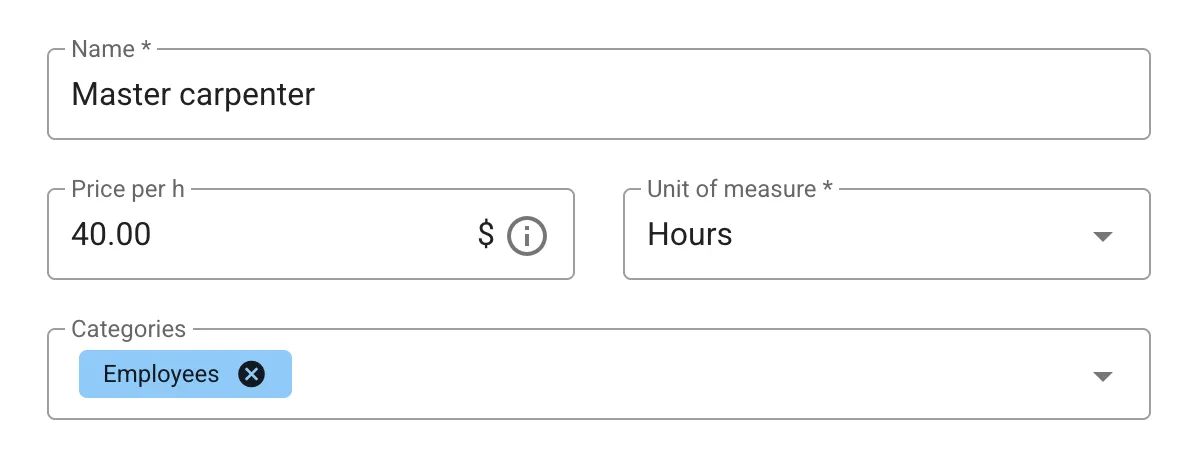

Labor Cost Tracking

Add your production staff to the system along with their labor rates.

Include processing time in your bill of materials, and Controlata will automatically calculate labor costs as part of your product costing.

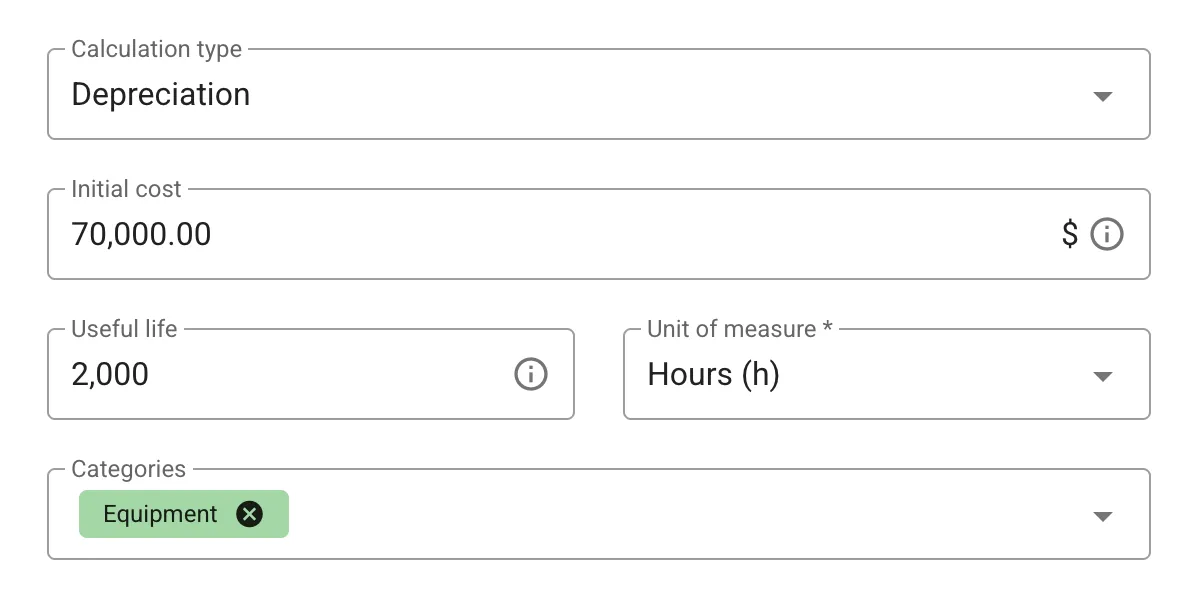

Equipment Depreciation

Add your equipment to the system along with its cost and expected lifetime.

Include this equipment in your bill of materials, and Controlata will automatically calculate depreciation costs as part of your product costing.

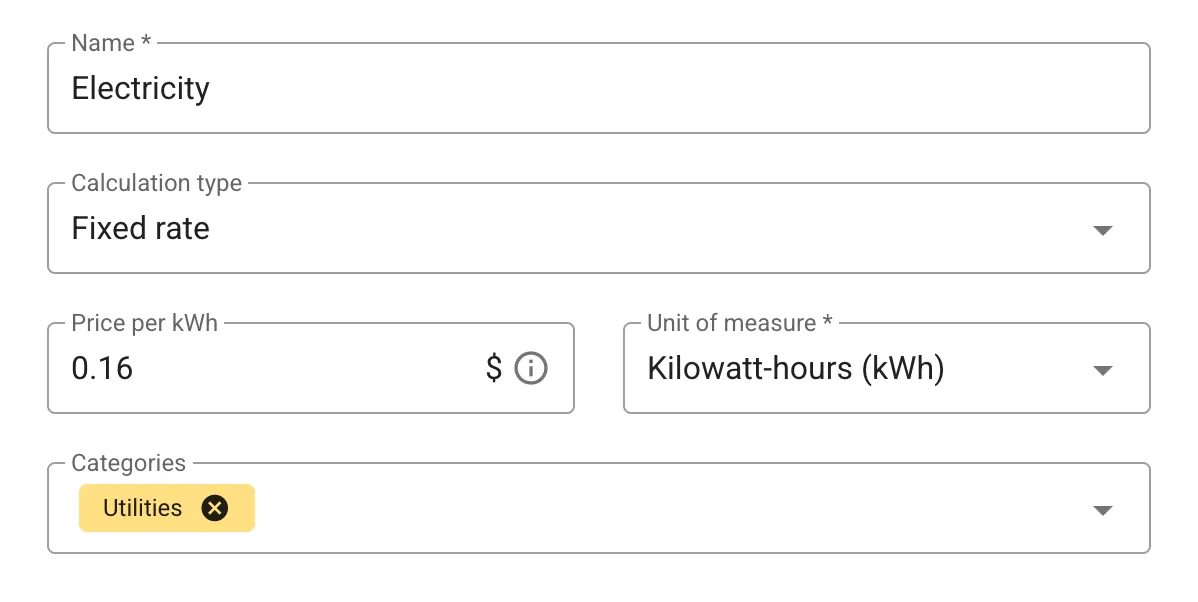

Utility Costs

Want to include electricity costs in your product pricing? Add utility rates to the system and include them in your bill of materials. Controlata will automatically calculate utility costs as part of your product costing.

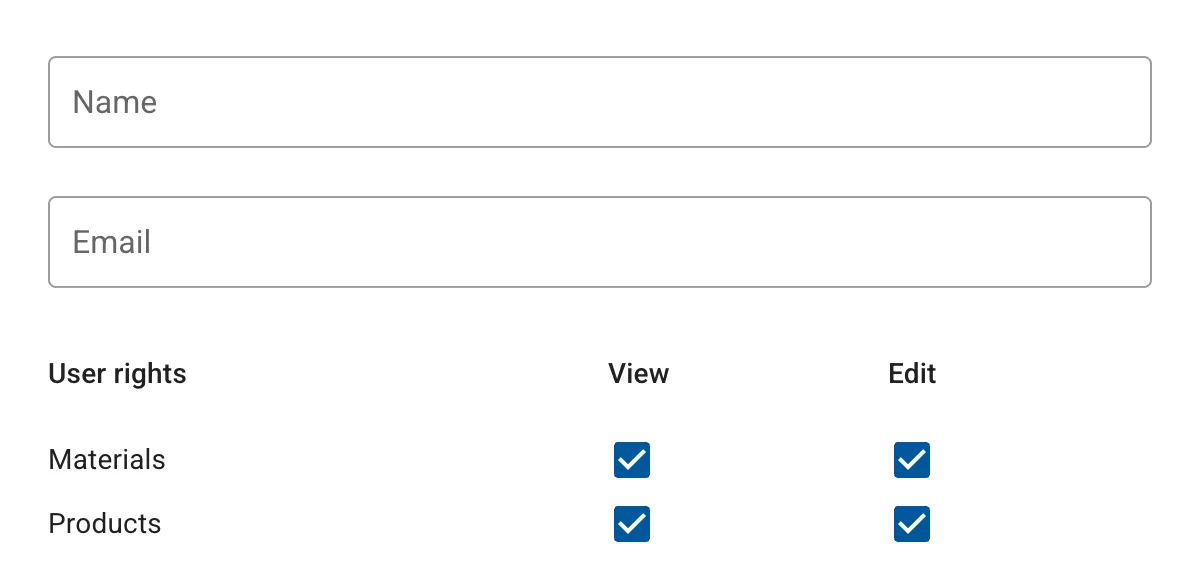

Team Management

Add team members to help manage production and track inventory levels together.

Control access by assigning specific permissions to each user based on their role.

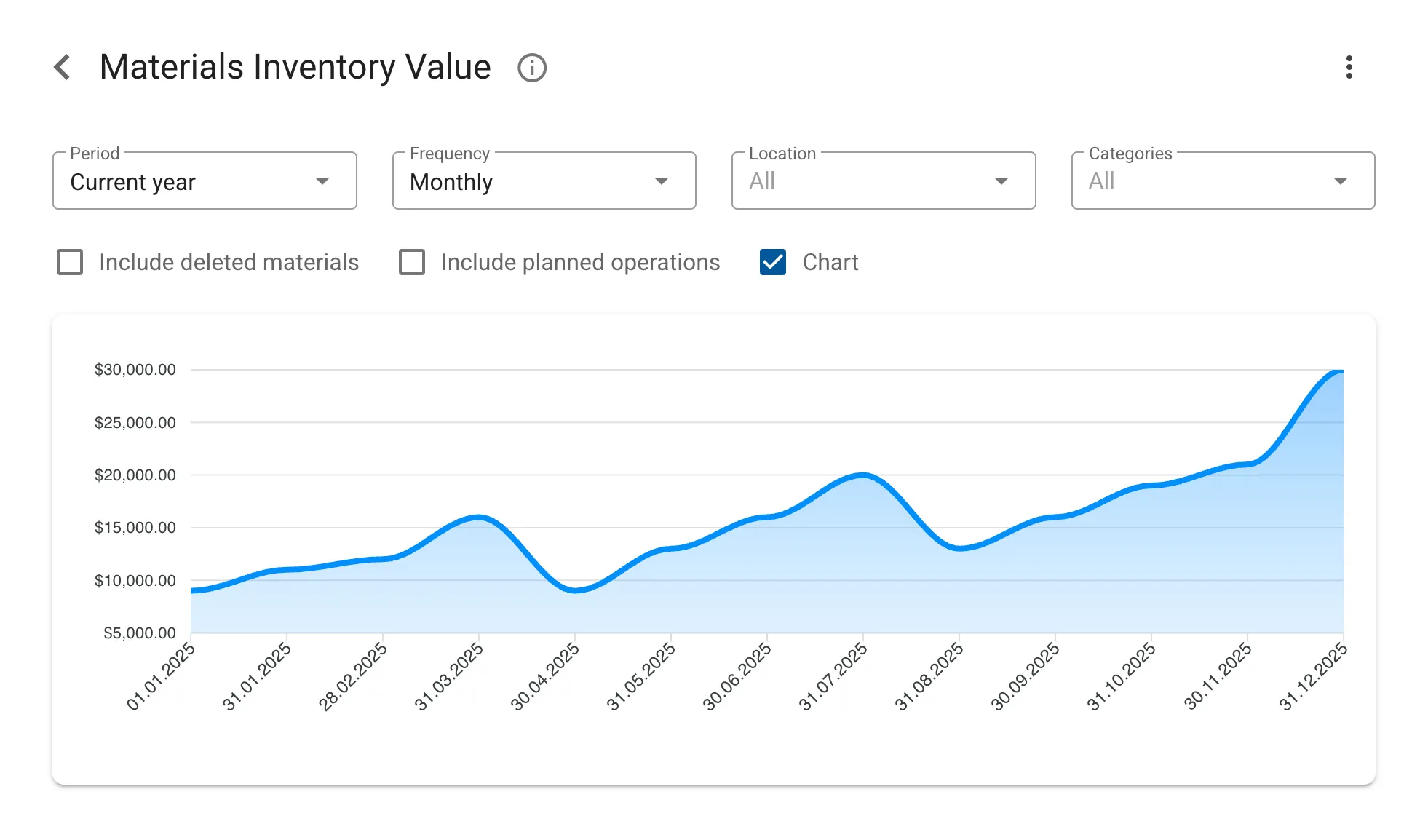

Financial Reports and Analytics

Controlata provides over 20 different types of reports, including:

- Stock movement reports

- Inventory status

- Purchase and sales price trends

- ABC analysis of materials and products

Export any report to Excel for further analysis.

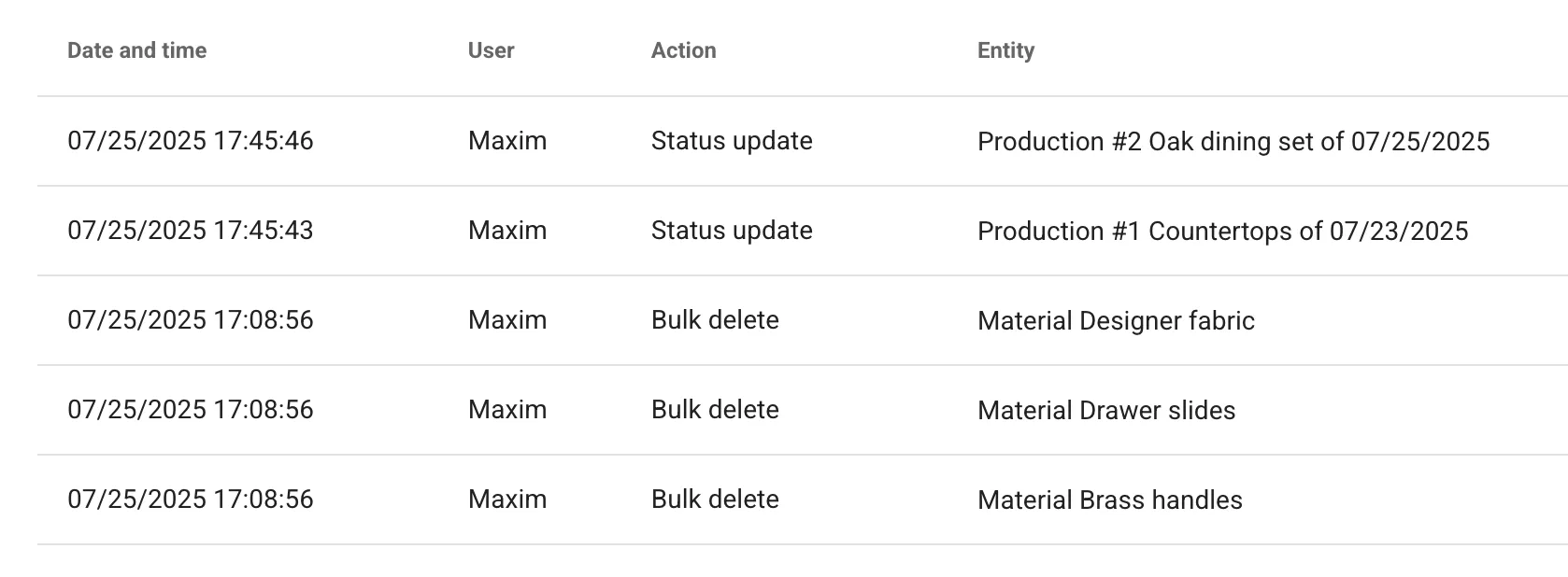

Activity Log

You can always access the activity log of all users in the system.

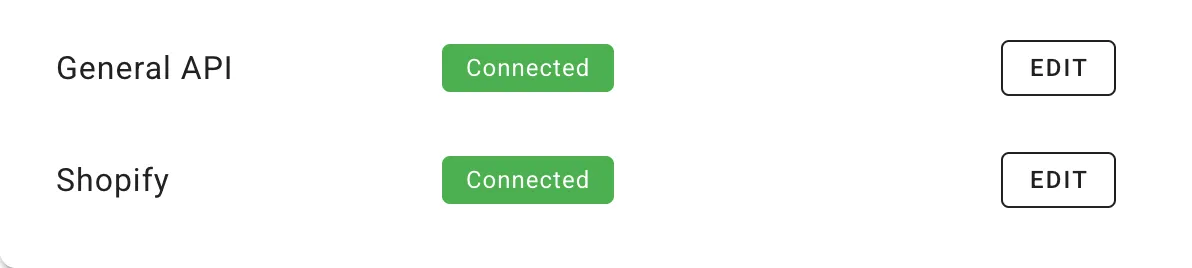

Integrations

Automatically receive orders from your Shopify store and sync inventory levels in real-time. Keep your online and offline stock always up to date.

Use our open API to integrate with other services and automate your workflows. API supports orders, products, and customers.

Try Controlata

Optimize your manufacturing operations

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.