Coffee Roasting Software for Inventory Management

Streamline your coffee roasting business with comprehensive inventory management software. Track green beans, calculate roasting costs, and optimize production planning for consistent quality and profitability.

Essential Features for Coffee Roasters

Controlata provides specialized tools designed specifically for coffee roasting businesses to manage every aspect of your operation efficiently.

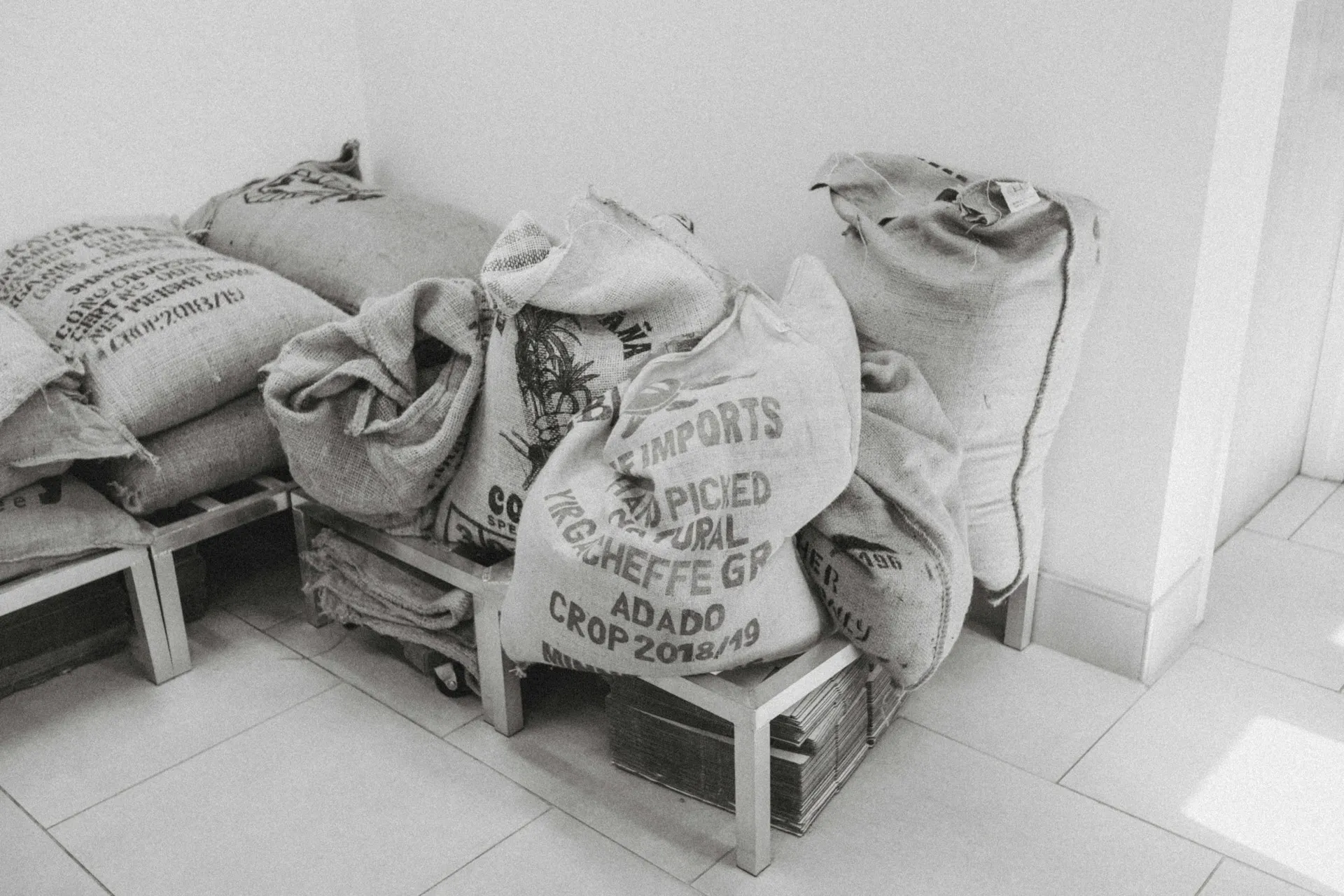

Green Bean Inventory Tracking

Comprehensive green bean inventory management:

- Track origins, processing methods, and arrival dates,

- Monitor current stock levels and consumption rates,

- Set low stock alerts for seasonal beans,

- Manage supplier relationships and certifications.

Always know exactly what green coffee inventory you have available for roasting.

Roasting Cost Calculation

Accurate cost analysis for every roast batch:

- Calculate green bean costs with shrinkage rates,

- Include energy and labor costs per batch,

- Track packaging and labeling expenses,

- Monitor profitability by roast profile.

Get precise cost data to price your coffee products competitively and maintain healthy margins.

Roasting Production Planning

Optimize your roasting schedule and operations:

- Plan batches based on customer orders,

- Schedule roasting sessions efficiently,

- Balance inventory with demand forecasts,

- Coordinate cupping and quality control.

Ensure consistent supply while minimizing waste and maximizing freshness.

Why Coffee Roasters Choose Controlata

Join hundreds of successful coffee roasting businesses using Controlata to improve operations and increase profitability.

Perfect Bean Inventory Control

Never run out of seasonal beans or overstock. Track green coffee inventory with origin details, purchase dates, and optimal usage windows for consistent quality.

Precise Roasting Costs

Calculate exact costs per batch including bean shrinkage, energy consumption, and labor. Set profitable prices based on real data, not guesswork.

Optimized Roasting Schedule

Plan roasting sessions efficiently based on orders and inventory. Reduce waste, improve freshness, and meet customer demand consistently.

Quality Consistency Tracking

Maintain roasting profiles and track batch variations. Document cupping scores and quality metrics to ensure consistent flavor profiles.

Streamlined Order Fulfillment

Match customer orders with available roasted inventory. Plan production to meet delivery deadlines while maintaining optimal freshness.

Improved Profitability

Reduce waste through better planning, optimize buying cycles for green beans, and increase margins with accurate cost tracking and pricing strategies.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.