Metal Manufacturing Software

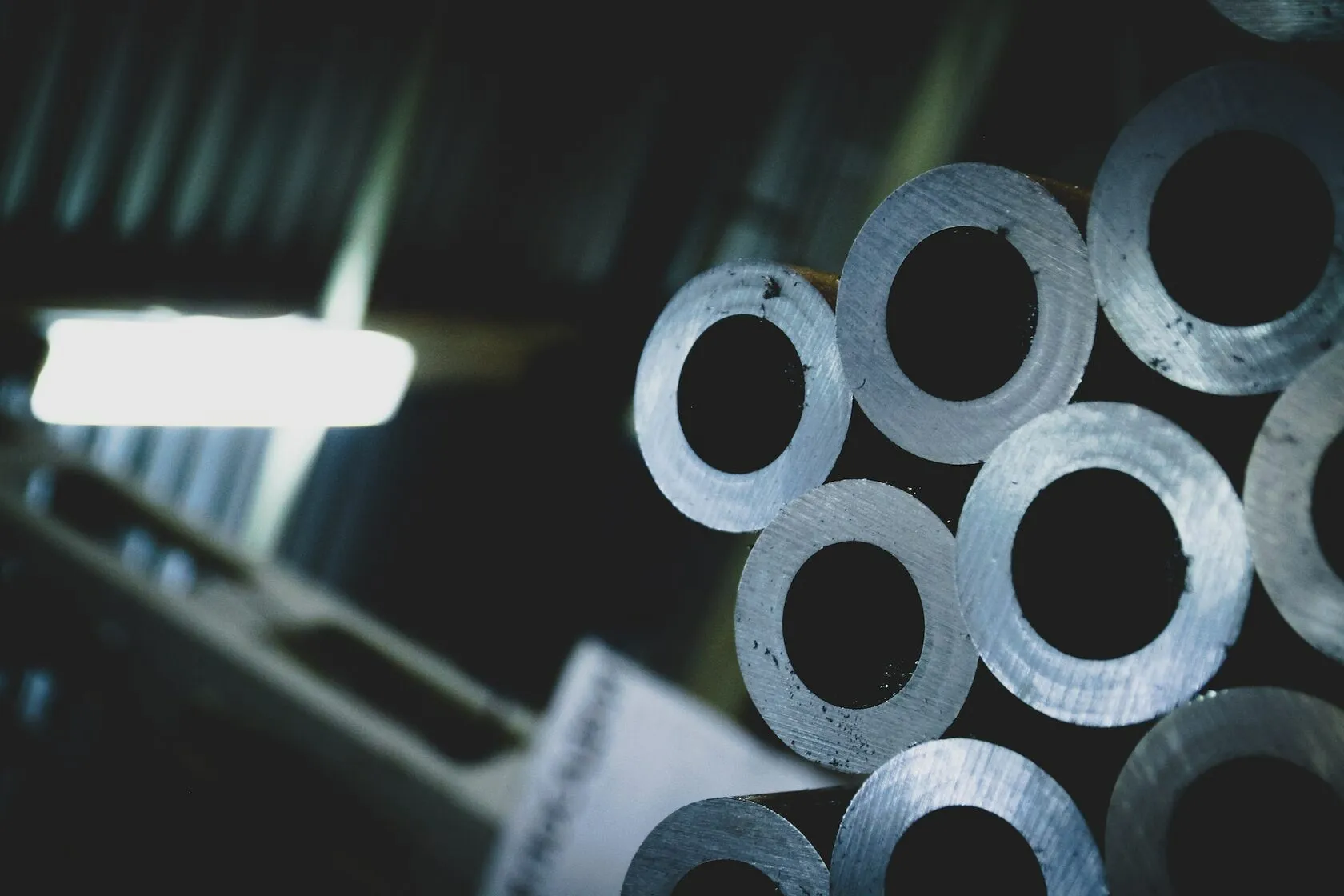

Comprehensive metal manufacturing software for tracking raw materials, calculating production costs, and planning operations. Manage steel, aluminum, and other metal inventory with real-time visibility across multiple locations.

Essential Features for Metal Manufacturing

Streamline your metal fabrication operations with specialized inventory management and production control tools designed for the metalworking industry.

Raw Materials Inventory Management

Track all metal materials and supplies in real-time:

- Steel sheets, bars, and structural components inventory tracking,

- Aluminum, copper, and specialty alloy stock management,

- Consumables and welding materials monitoring,

- Automated low-stock alerts for critical materials.

Maintain optimal inventory levels and prevent production delays with accurate material tracking.

Accurate Cost Calculation

Calculate precise production costs using FIFO method:

- Material costs based on actual purchase prices,

- Labor expenses for cutting, welding, and finishing operations,

- Equipment depreciation and overhead allocation,

- Real-time profitability analysis for each project.

Make informed pricing decisions with comprehensive cost breakdowns and margin analysis.

Production Planning and Scheduling

Plan and manage metal fabrication workflows efficiently:

- Job scheduling based on material availability and deadlines,

- Work order creation with detailed specifications,

- Progress tracking for cutting, forming, and assembly stages,

- Resource allocation optimization across production lines.

Ensure timely delivery and efficient resource utilization with comprehensive production planning.

Benefits for Metal Manufacturing Companies

Controlata helps metal fabricators optimize inventory, reduce waste, and improve profitability through intelligent manufacturing management.

Optimized Material Storage

Efficiently manage steel, aluminum, and specialty metal inventory across multiple storage locations with real-time visibility and automated reorder points.

Accurate Job Costing

Calculate precise production costs including material, labor, and overhead expenses to ensure profitable pricing and identify cost-saving opportunities.

Reduced Lead Times

Streamline production workflows and eliminate material shortages to consistently meet customer delivery deadlines and improve satisfaction.

Minimized Material Waste

Optimize material usage through accurate planning and tracking, reducing scrap rates and improving overall material efficiency in metal fabrication.

Improved Profitability

Gain clear visibility into project margins and production costs to make data-driven decisions that enhance overall business profitability.

Streamlined Operations

Integrate inventory management, production planning, and cost tracking in one system to eliminate manual processes and improve operational efficiency.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.