Equipment Manufacturing Software

Streamline your equipment and machinery manufacturing with comprehensive inventory management, precise cost tracking, and automated production planning. Built specifically for complex multi-component manufacturing processes.

Essential Tools for Equipment Manufacturing

Complete visibility and control over every component in your machinery production process

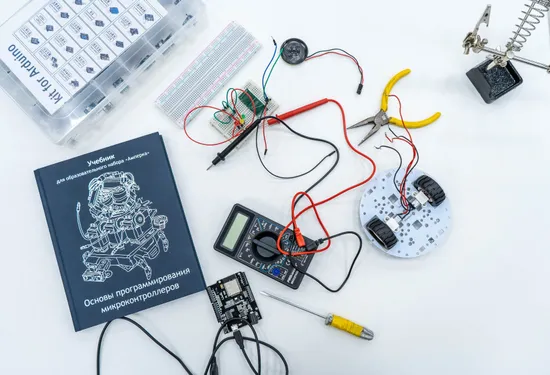

Component & Materials Tracking

Track every component in real-time:

- High-value machinery parts and assemblies,

- Raw materials and specialized components,

- Sub-assemblies and work-in-progress items,

- Finished equipment ready for delivery.

Maintain precise inventory control for complex equipment with hundreds of components.

Equipment Cost Calculation

Calculate accurate production costs automatically:

- Material costs using FIFO method for precision,

- Labor costs for assembly operations,

- Equipment depreciation and overhead allocation,

- Total manufacturing cost per unit.

Get precise cost breakdowns for complex machinery and equipment manufacturing.

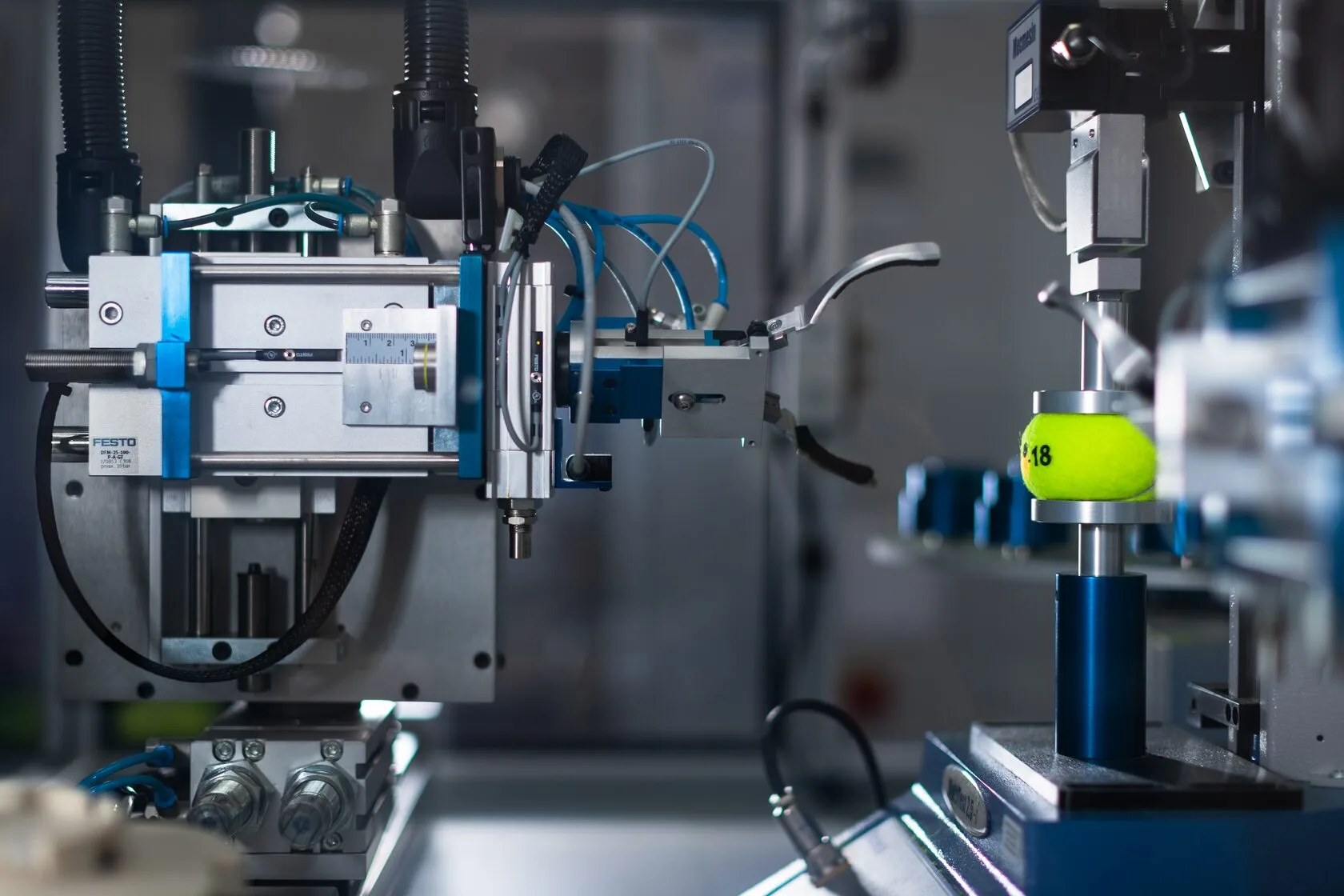

Production Planning & Scheduling

Plan and manage equipment manufacturing:

- Production schedules based on order priorities,

- Material availability checks before production,

- Assembly sequence optimization,

- Delivery timeline forecasting.

Ensure on-time delivery of complex equipment with coordinated production planning.

Why Equipment Manufacturers Choose Controlata

Specialized features designed for the unique challenges of machinery and equipment production

Handle Complex Equipment Assembly

Manage products with 100+ components efficiently. Track every bolt, circuit, and assembly through your manufacturing process with precision.

Accurate Equipment Costing

Calculate true manufacturing costs including expensive components, specialized labor, and equipment depreciation for profitable pricing decisions.

Meet Equipment Delivery Deadlines

Plan production schedules considering component lead times and assembly complexity to deliver machinery on schedule every time.

Optimize Expensive Inventory

Minimize working capital tied up in high-value components while ensuring availability for production commitments.

Real-time Production Visibility

Track assembly progress, identify bottlenecks, and coordinate teams across complex equipment manufacturing workflows.

Improve Equipment Profitability

Analyze costs, margins, and efficiency metrics to optimize your equipment manufacturing operations and increase profitability.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.