Inventory Audits for Manufacturing

Controlata is an intuitive inventory audit solution designed for manufacturing businesses. Streamline your stock counting process and maintain accurate inventory levels across raw materials, work in progress, and finished goods. Our software helps you optimize storage locations, identify discrepancies, and prevent inventory losses.

Inventory Audit Tools for Manufacturing

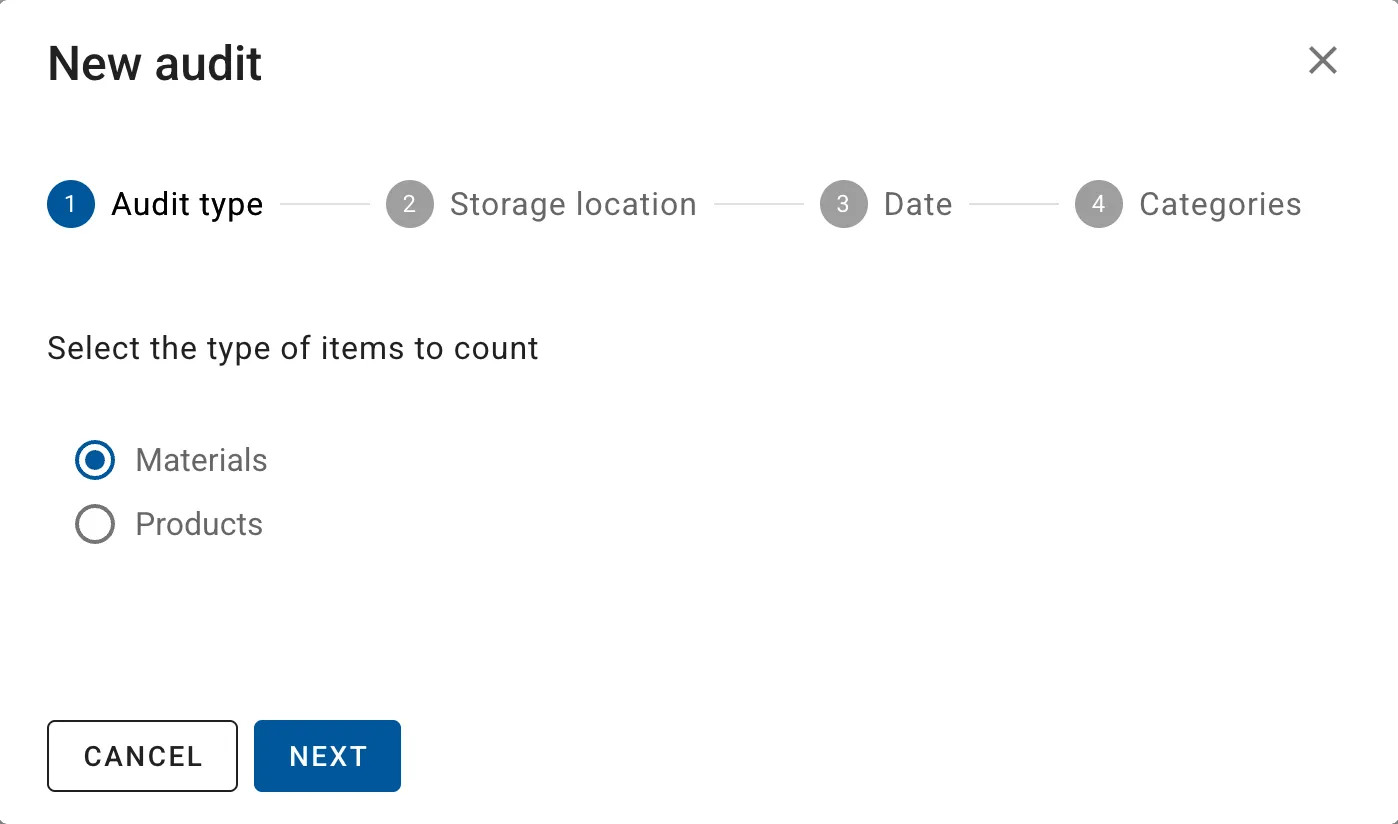

Raw Materials Inventory Audit

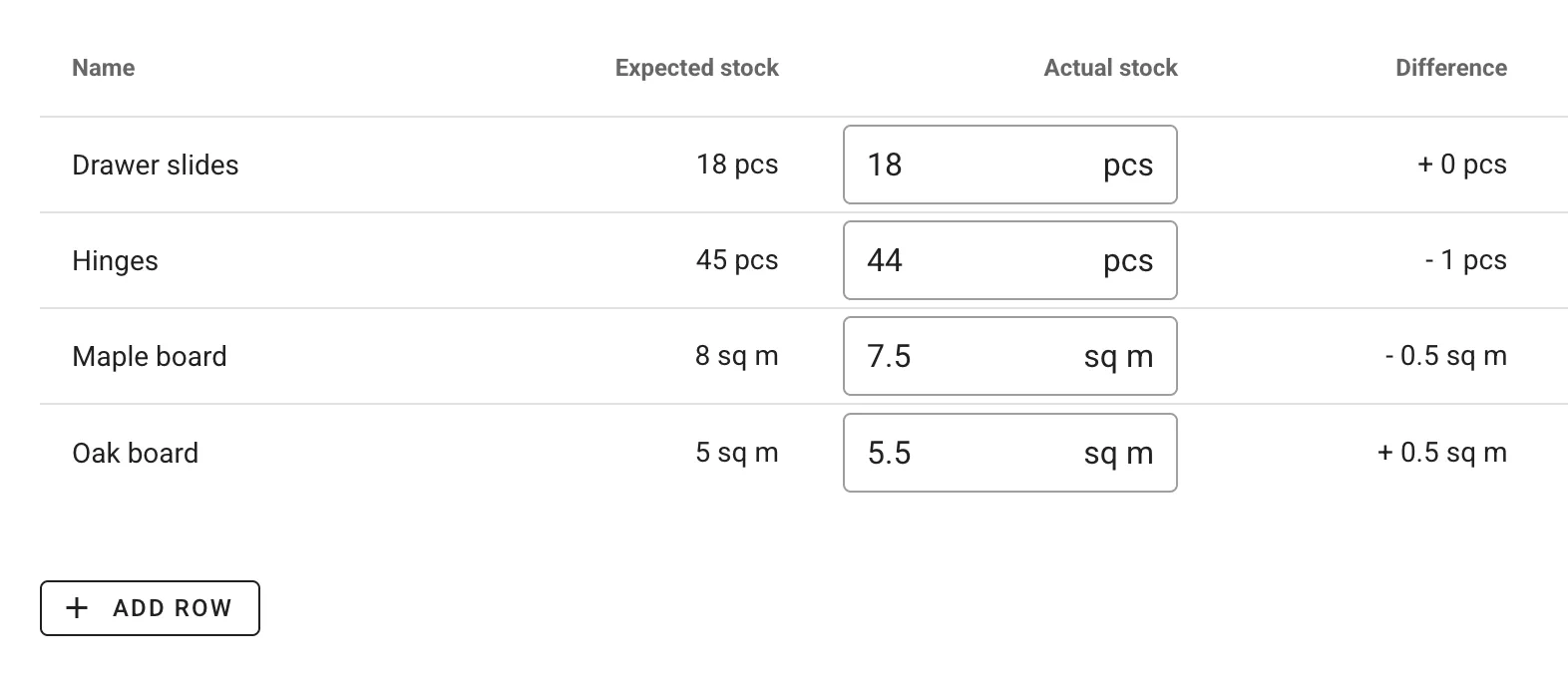

Streamline your materials counting process with our intuitive audit tools. Simply create an audit document, specify locations and items to verify, and record actual quantities for comparison with system data. Maintain accurate stock levels and identify discrepancies effortlessly.

Work in Progress Audit

Gain complete visibility into your production process with WIP auditing capabilities. Monitor components and assemblies across manufacturing stages, ensuring accurate tracking of all materials in production. Compare real-time WIP quantities against planned production orders.

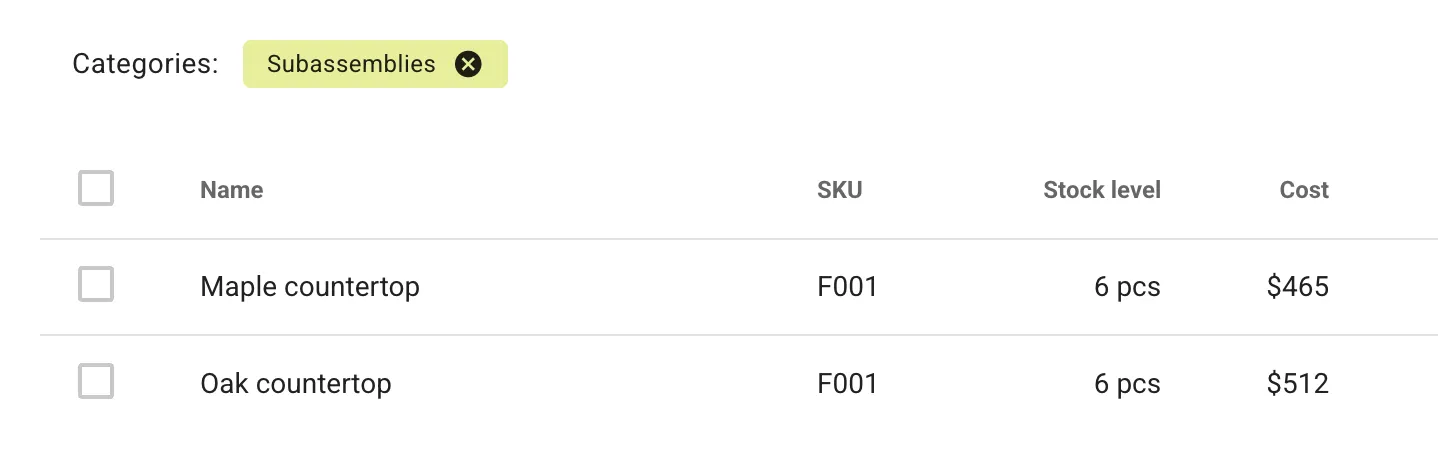

Finished Goods Inventory Audit

Ensure accurate finished goods tracking with dedicated audit functionality. Create and manage audits for your finished products storage, validate actual quantities, and automatically reconcile with expected inventory levels for complete stock control.

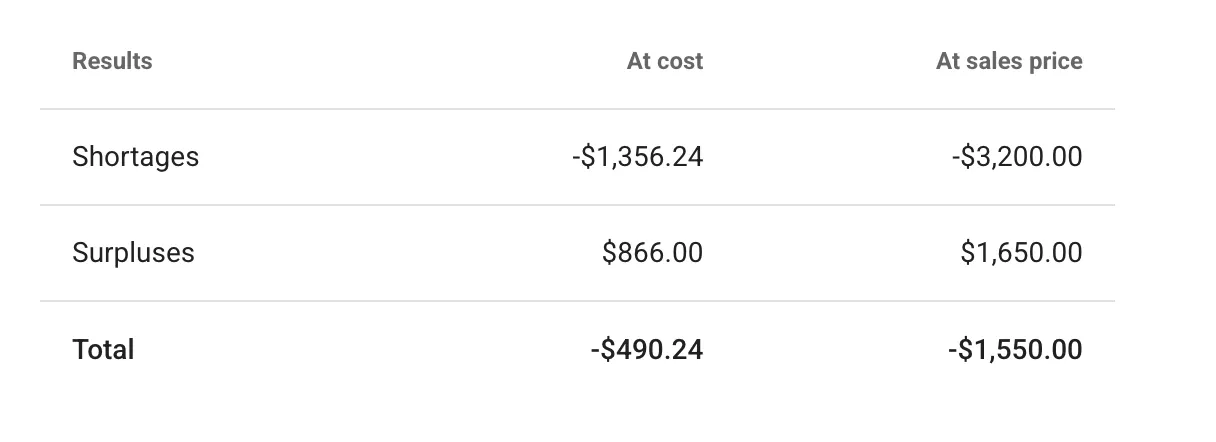

Audit Results Documentation

Generate comprehensive variance reports with automated documentation features. Get instant insights into inventory discrepancies, create official audit records, and make informed decisions about inventory adjustments based on accurate data.

Variance Analysis

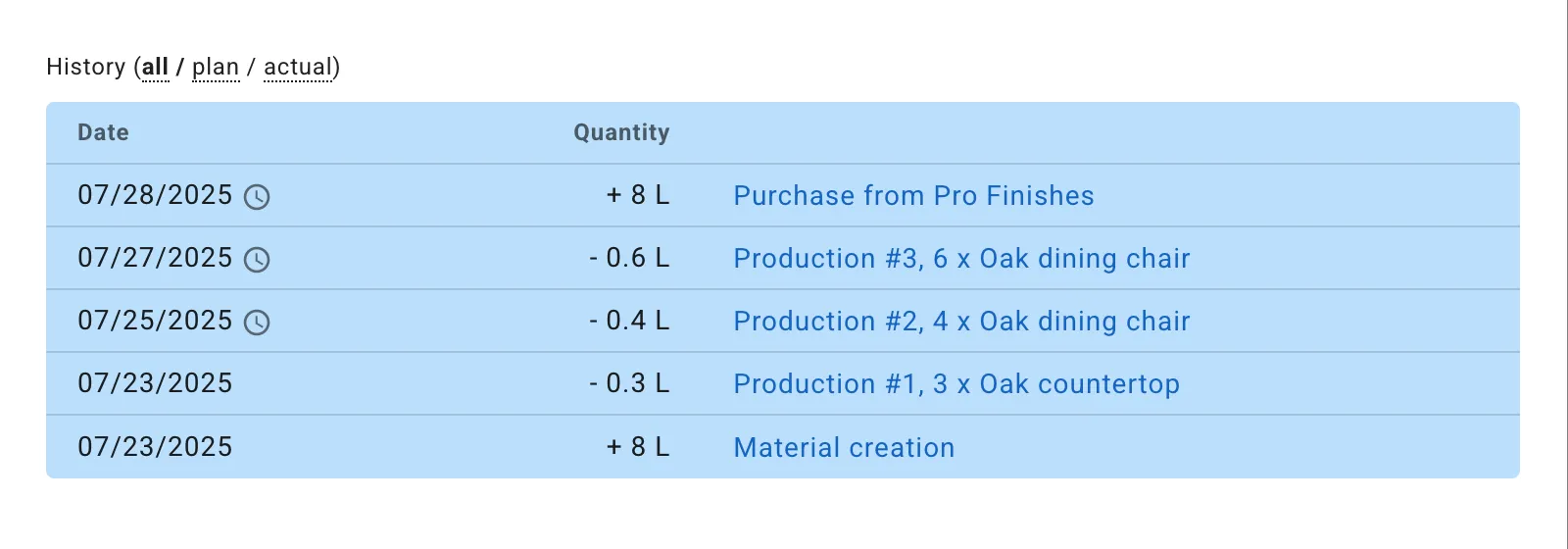

Optimize inventory accuracy with detailed movement analysis tools. Track item history including receipts, production updates, returns, and transfers to identify discrepancy sources. Use built-in analytics to prevent future variances and improve inventory management.

Key Benefits of Controlata's Inventory Audit

Speed and Efficiency

Streamline your inventory counting process by eliminating manual paperwork, calculator calculations, and complex Excel spreadsheets. Our digital solution significantly reduces audit completion time.

Error Prevention

Minimize human error with automated validation checks. The system ensures complete item coverage, correct unit conversions, and precise calculations during the audit process.

Result Transparency

Instantly identify discrepancies between actual and recorded inventory levels. Investigate variances and make informed decisions about stock adjustments with comprehensive audit trails.

Process Control

Track audit activities with detailed logs of who performed counts, when they occurred, and what discrepancies were found. Enhance accountability and prevent unauthorized adjustments.

Seamless Integration

Automatically sync audit findings with your inventory management, production tracking, cost calculations, and financial reporting systems for complete data consistency.

Compliance Assurance

Minimize regulatory risks and potential penalties by maintaining accurate inventory records. Regular audits with Controlata help ensure compliance with accounting and tax requirements.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.