Manufacturing Cost Estimating Software

Controlata provides precise manufacturing cost estimating software designed for production companies. Calculate accurate product costs, optimize pricing strategies, and maximize profitability with comprehensive cost analysis and real-time data.

Comprehensive Manufacturing Cost Estimating Features

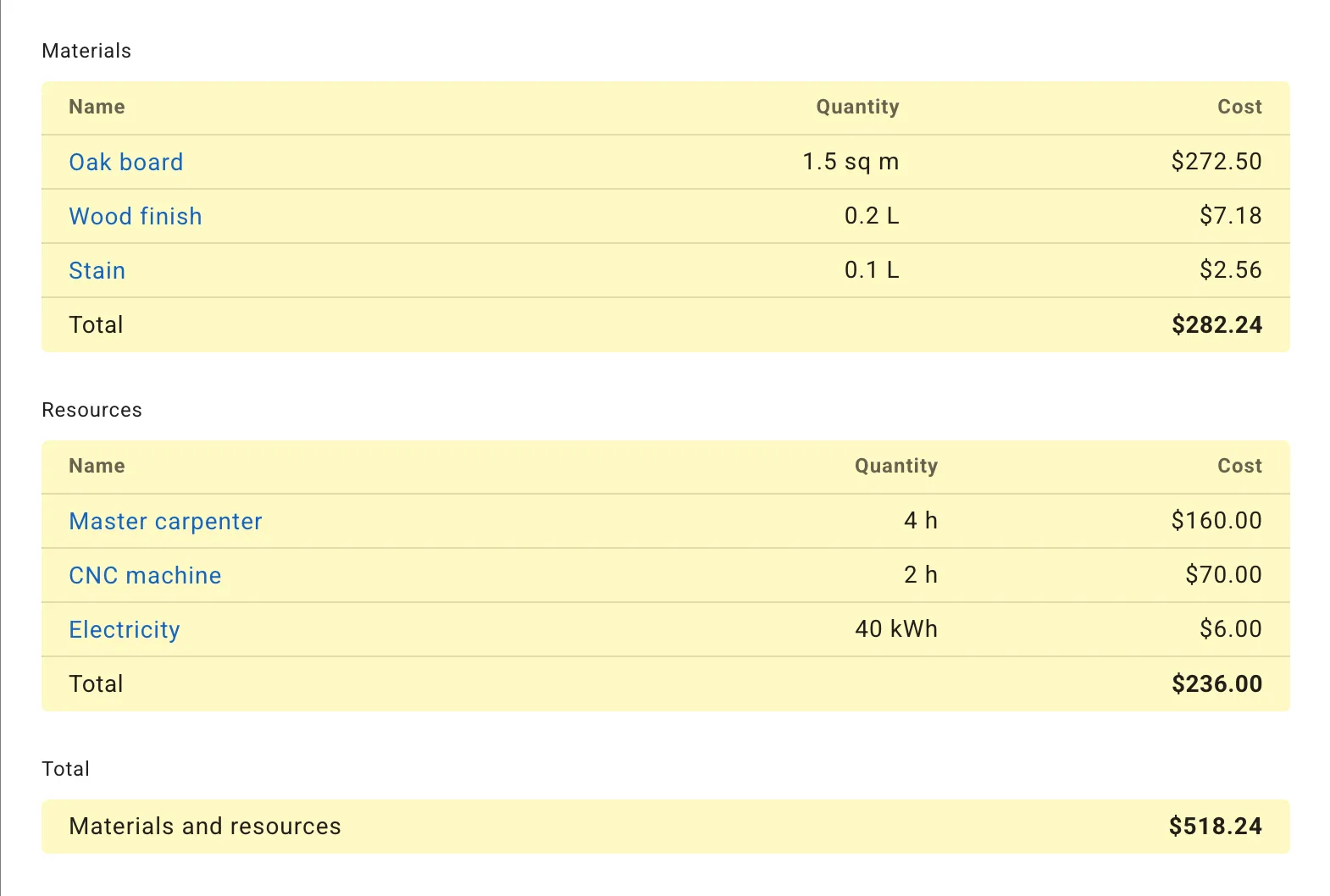

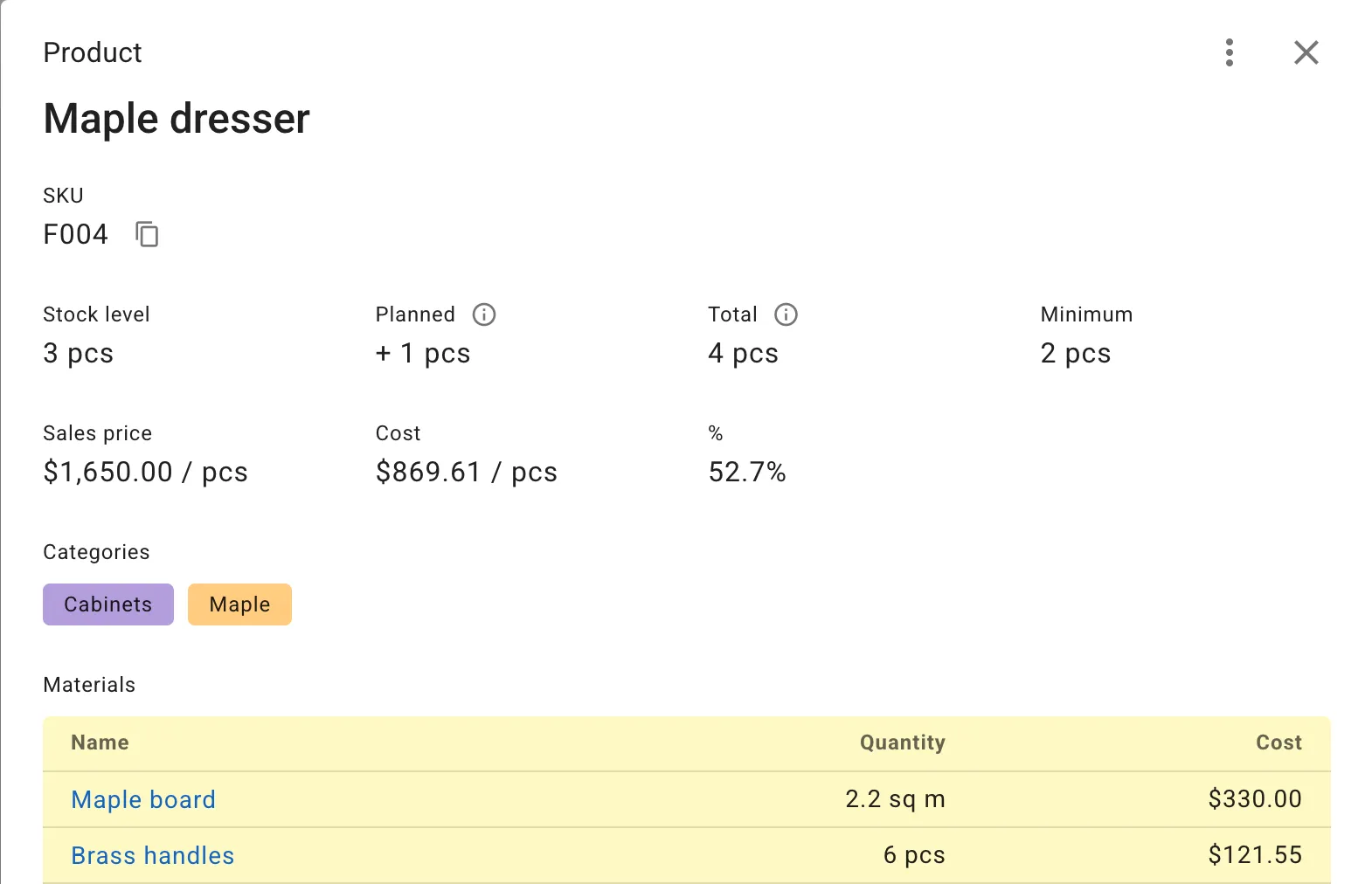

Automated Cost Calculation

Calculate precise manufacturing costs automatically based on your bill of materials, labor rates, and overhead expenses. Our manufacturing costs software ensures accuracy and eliminates manual calculation errors for reliable cost estimates.

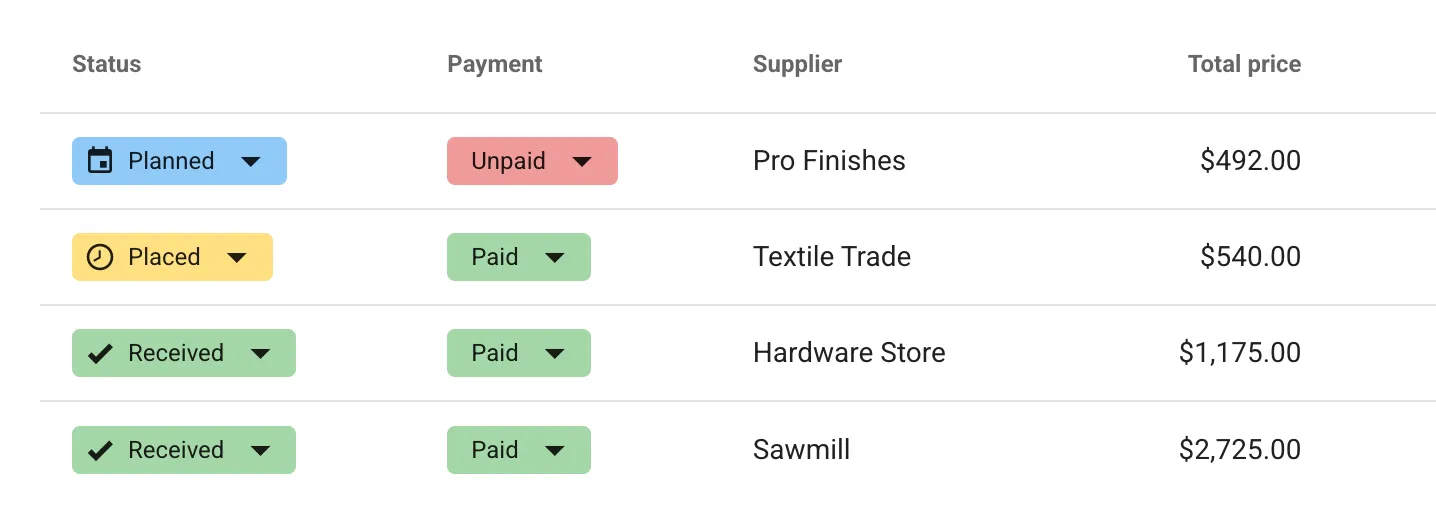

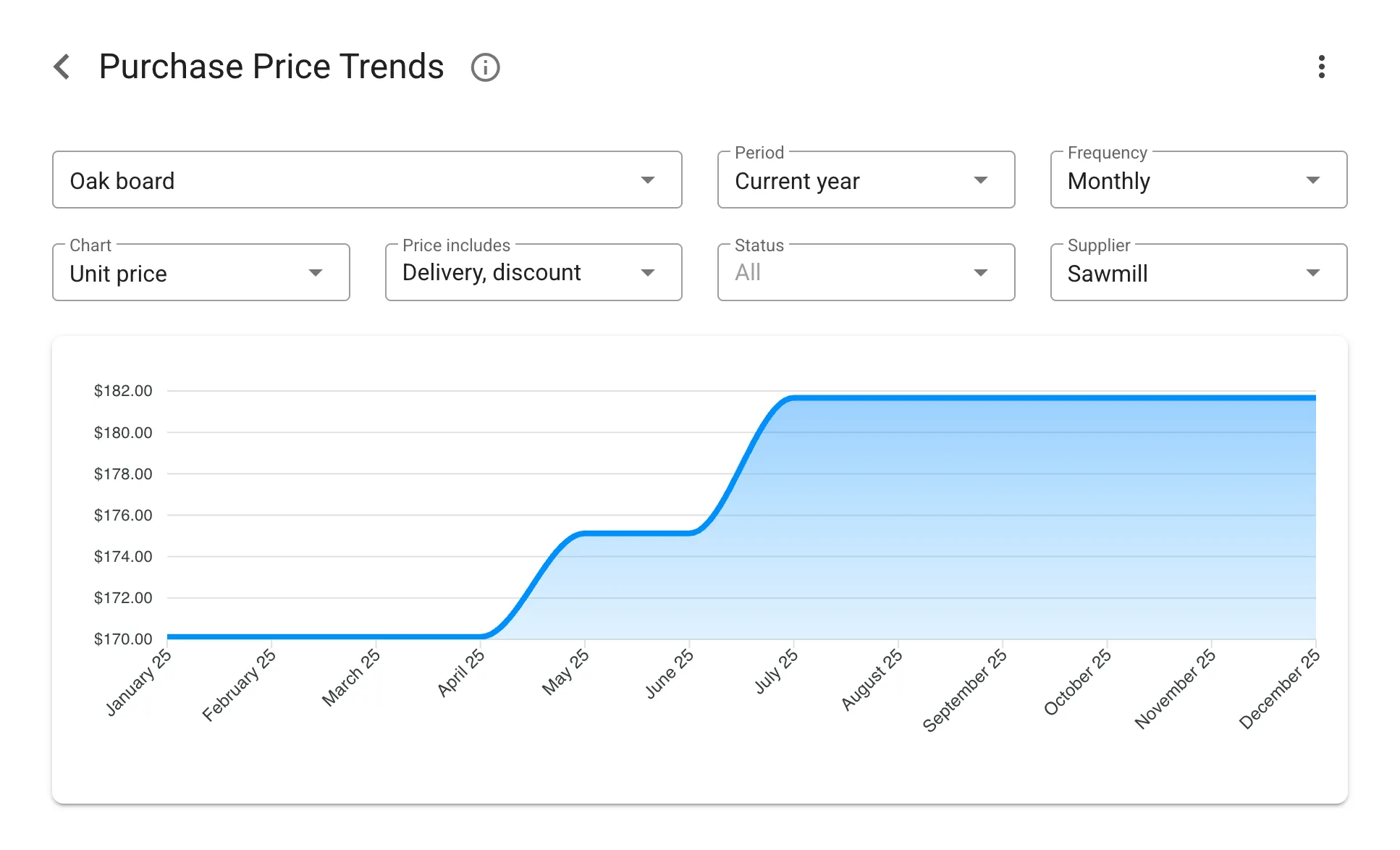

Real-time Material Pricing

Track material costs in real-time with automatic price updates from suppliers. Monitor cost fluctuations and adjust your estimates instantly to maintain accurate pricing and protect profit margins.

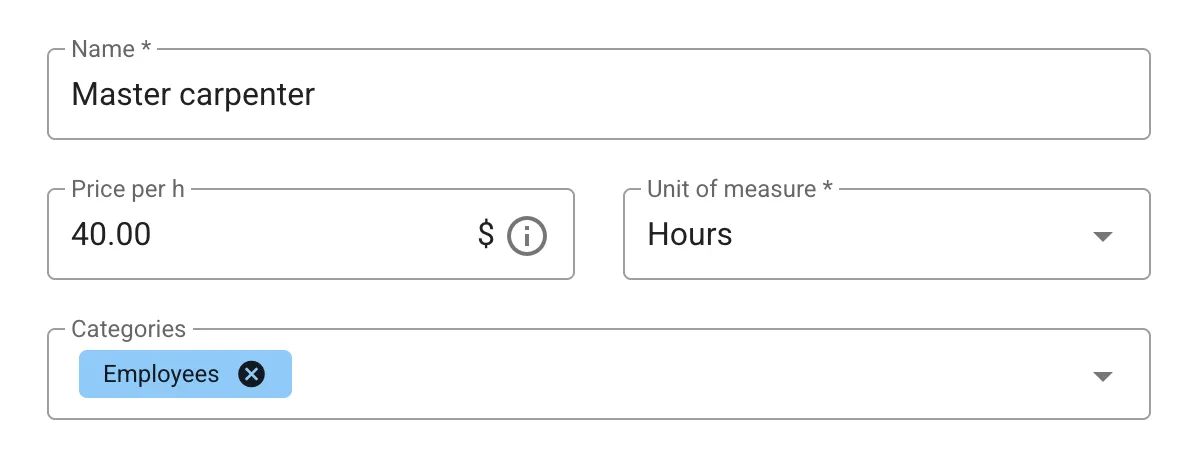

Labor Cost Tracking

Calculate labor costs accurately with detailed time tracking and rate management. Include direct labor, indirect costs, and benefits in your manufacturing cost estimates for complete visibility into production expenses.

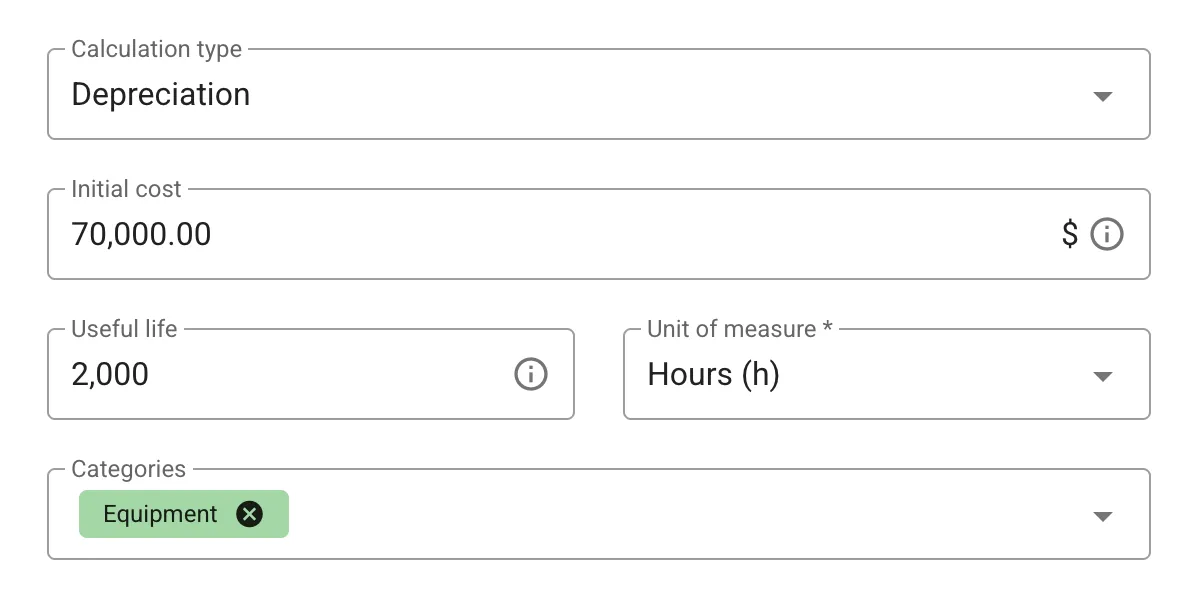

Overhead Allocation

Distribute overhead costs accurately across products using multiple allocation methods. Track facility costs, utilities, equipment depreciation, and administrative expenses for comprehensive cost estimating.

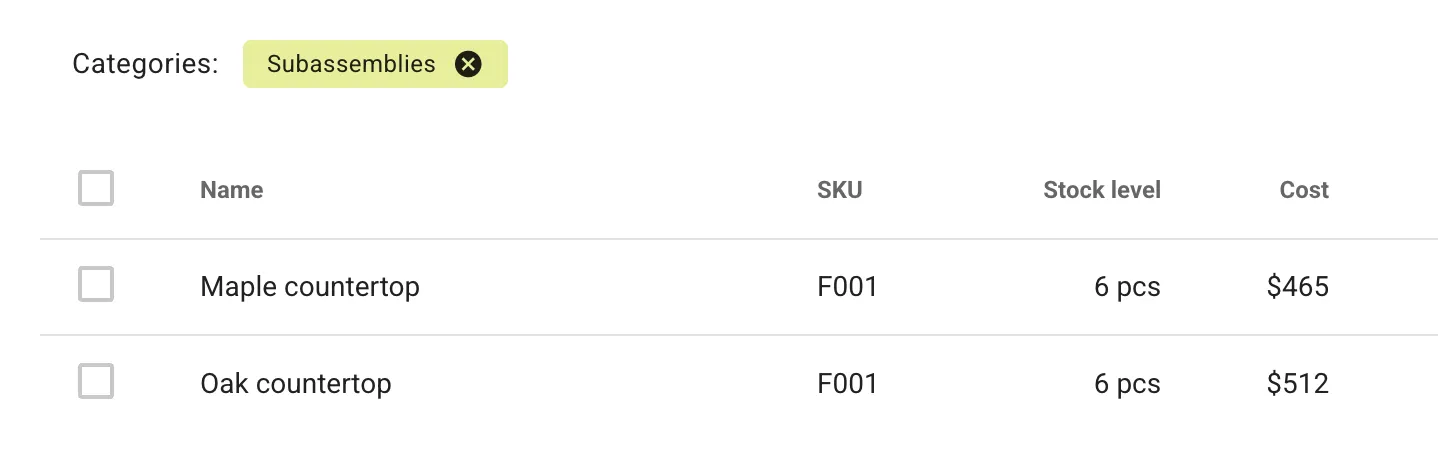

Multi-level Manufacturing Costs

Handle complex manufacturing structures with sub-assemblies and components. Calculate costs at every production level, from raw materials to finished goods, ensuring complete cost visibility throughout your manufacturing process.

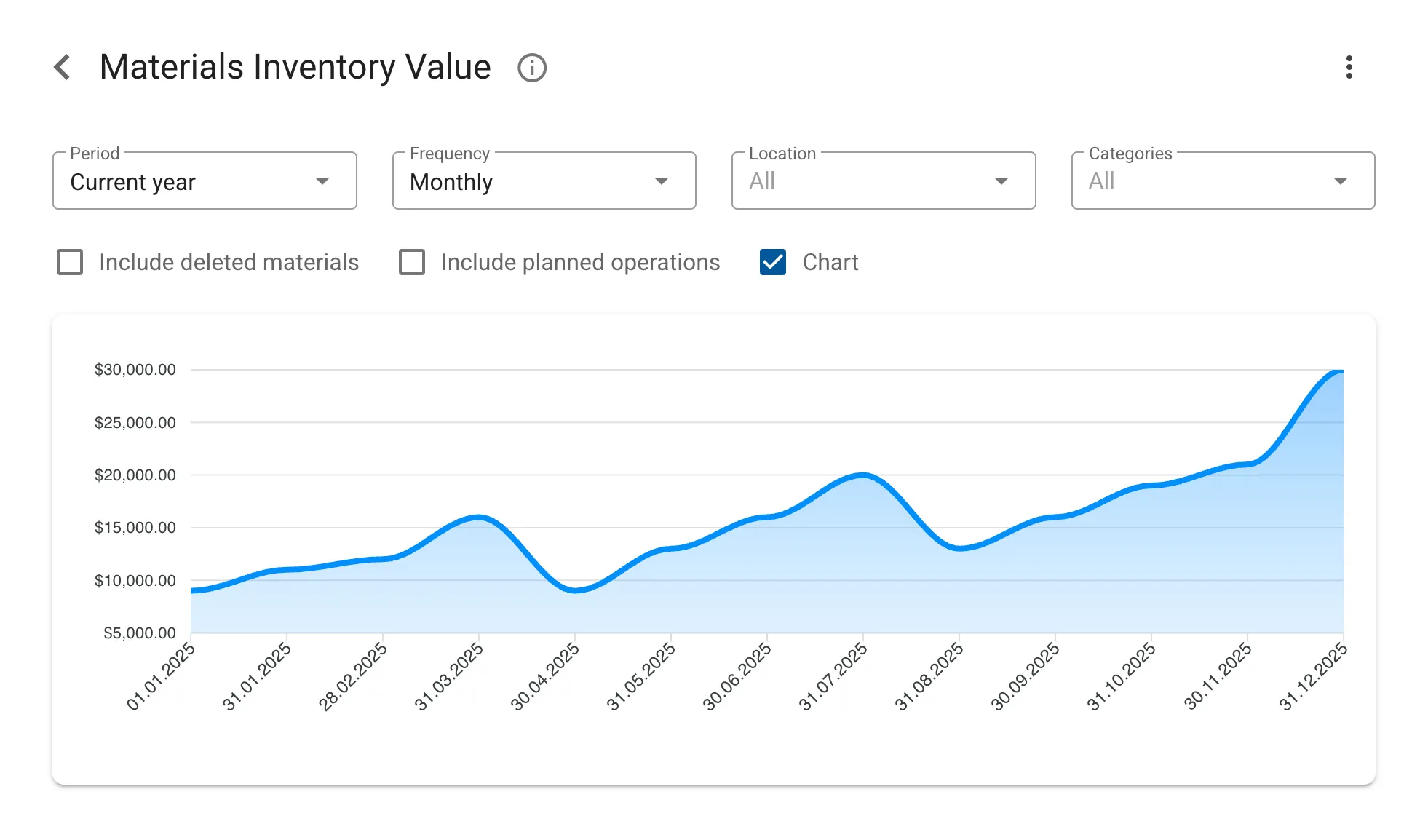

Historical Cost Analysis

Access historical cost data to identify trends and improve future estimates. Compare actual costs against estimates to refine your costing accuracy and make informed pricing decisions.

Profit Margin Analysis

Calculate profit margins instantly with built-in markup and margin calculators. Analyze profitability at product and order levels to optimize your pricing strategy and maximize revenue.

Cost Reports & Analytics

Generate detailed cost reports and analytics to track manufacturing expenses across all products and time periods. Export data to Excel for further analysis and create comprehensive cost breakdowns for management review.

Optimize Manufacturing Costs and Profitability

Transform your cost estimating process with Controlata's powerful manufacturing costs software. Our solution helps you:

Precise Cost Calculations

Eliminate guesswork with automated cost calculations based on accurate material prices, labor rates, and overhead allocation. Ensure every estimate reflects true manufacturing costs.

Improved Profit Margins

Optimize pricing strategies with detailed cost breakdowns and profit analysis. Identify cost reduction opportunities and maintain competitive margins across all products.

Cost Trend Analysis

Monitor cost trends over time to identify patterns and forecast future expenses. Use historical data to improve estimate accuracy and make informed business decisions.

Faster Cost Estimation

Reduce cost calculation time from hours to minutes with automated bill of materials processing and real-time cost updates. Respond to pricing requests faster and make quicker decisions.

Enhanced Accuracy

Achieve greater cost estimating precision with real-time data integration and systematic cost tracking. Reduce estimation errors and improve project profitability.

Financial Control

Gain complete visibility into manufacturing costs with detailed reporting and analytics. Monitor cost performance and identify areas for operational improvement and savings.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.