Manufacturing Operations Management Software

Transform your manufacturing operations with Controlata's comprehensive management platform. Our software integrates production planning, real-time monitoring, and workflow optimization to streamline your entire manufacturing process and maximize operational efficiency.

Comprehensive Manufacturing Operations Management

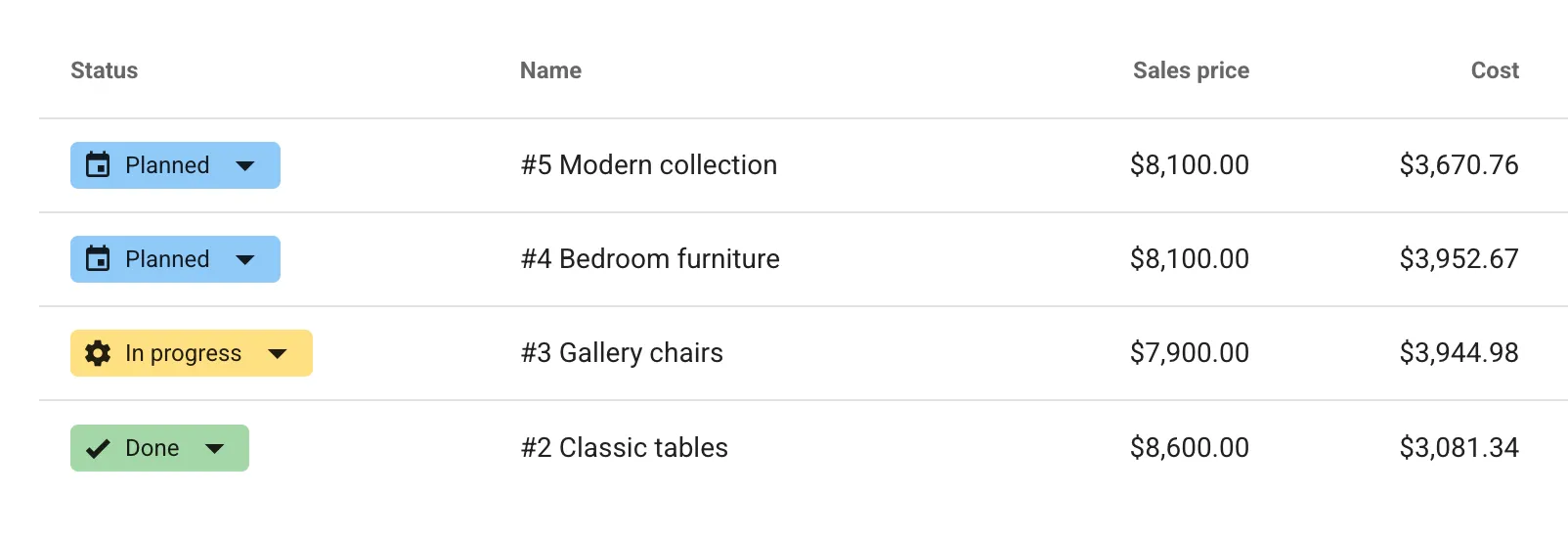

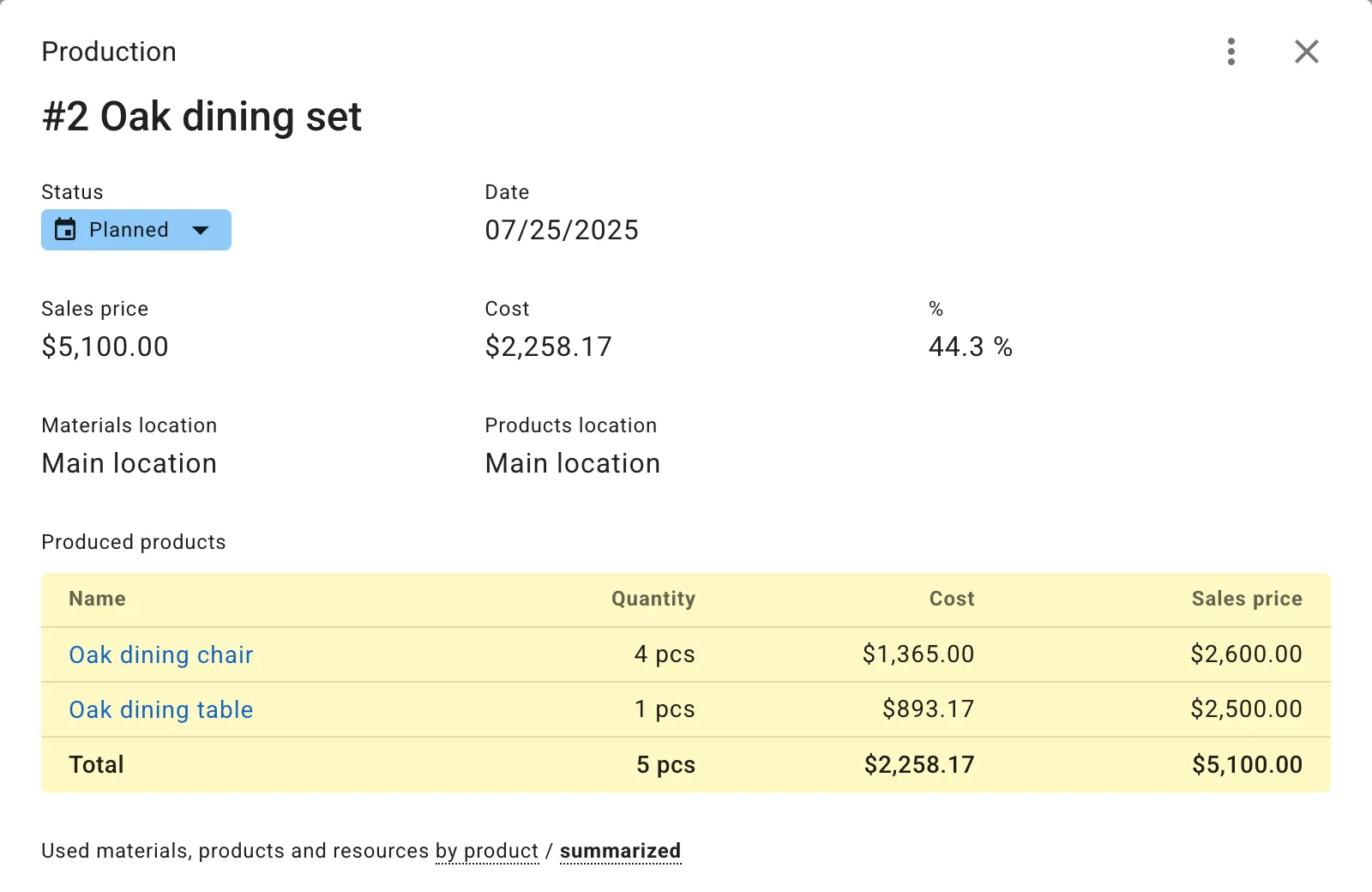

Production Planning & Scheduling

Plan and schedule your manufacturing operations with precision. Optimize production sequences, allocate resources efficiently, and maintain optimal workflow across all production lines. Automatic scheduling adjustments ensure maximum productivity.

Real-time Operations Monitoring

Monitor your manufacturing operations in real-time with comprehensive dashboards. Track production progress, identify bottlenecks instantly, and make data-driven decisions to optimize performance across all manufacturing processes.

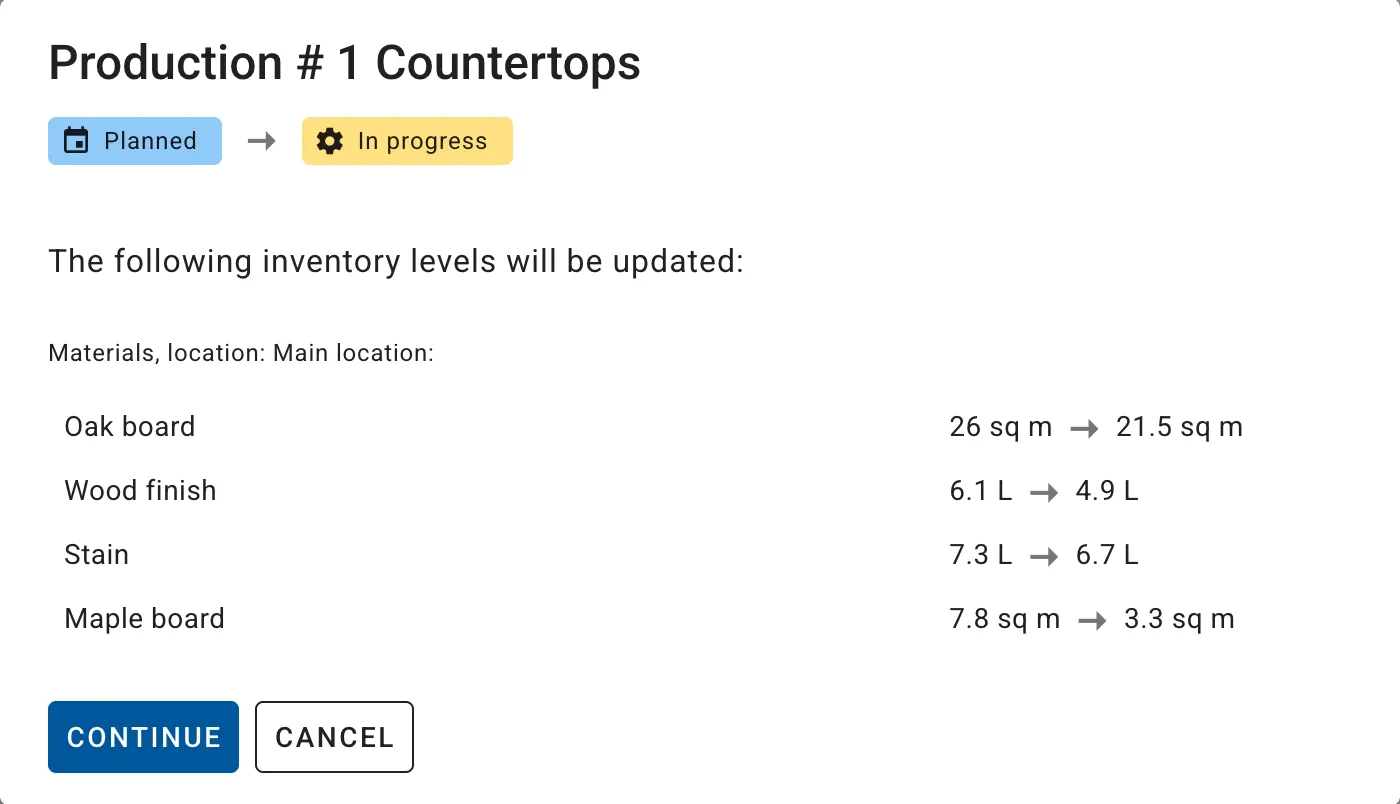

Workflow Automation

Automate critical manufacturing workflows to reduce manual tasks and minimize errors. Streamline material flows, automate status updates, and ensure consistent operational procedures throughout your manufacturing operations.

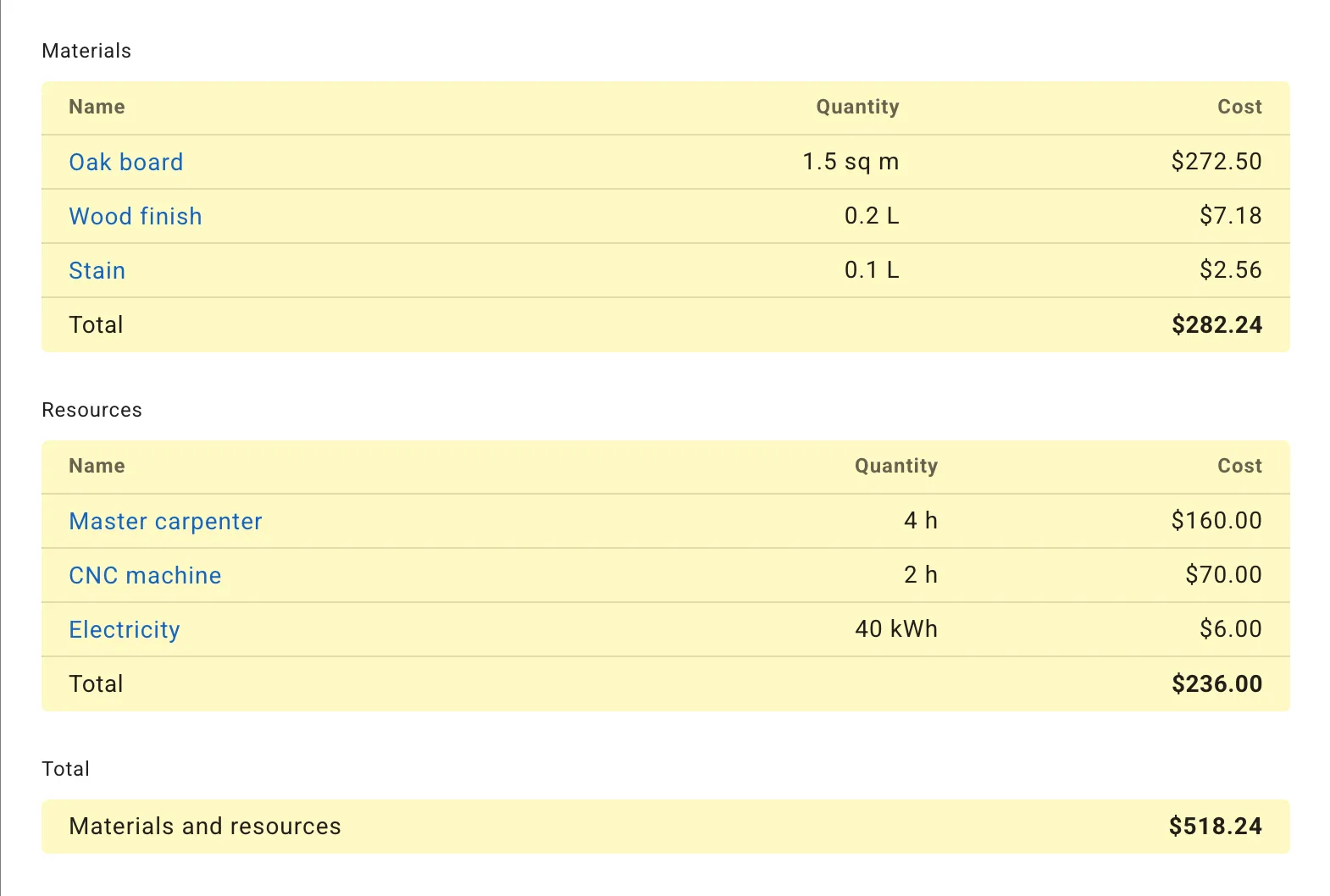

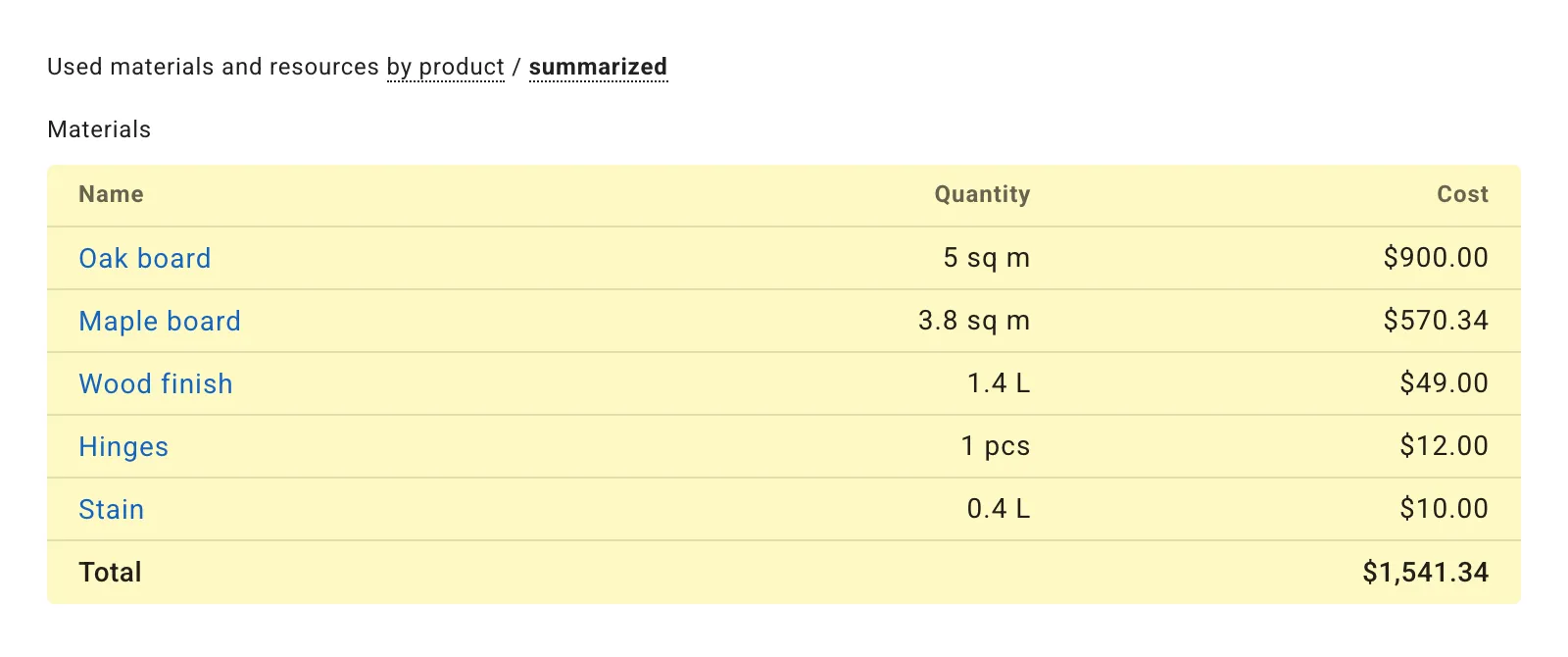

Bill of Materials Management

Create and manage detailed bills of materials for your manufacturing operations. Define material requirements, labor costs, equipment depreciation, and overhead expenses for accurate production planning and cost control.

Cost Calculation & Control

Automatically calculate manufacturing costs including materials, labor, equipment depreciation, and overhead expenses. Track actual costs against planned budgets and optimize your manufacturing operations profitability.

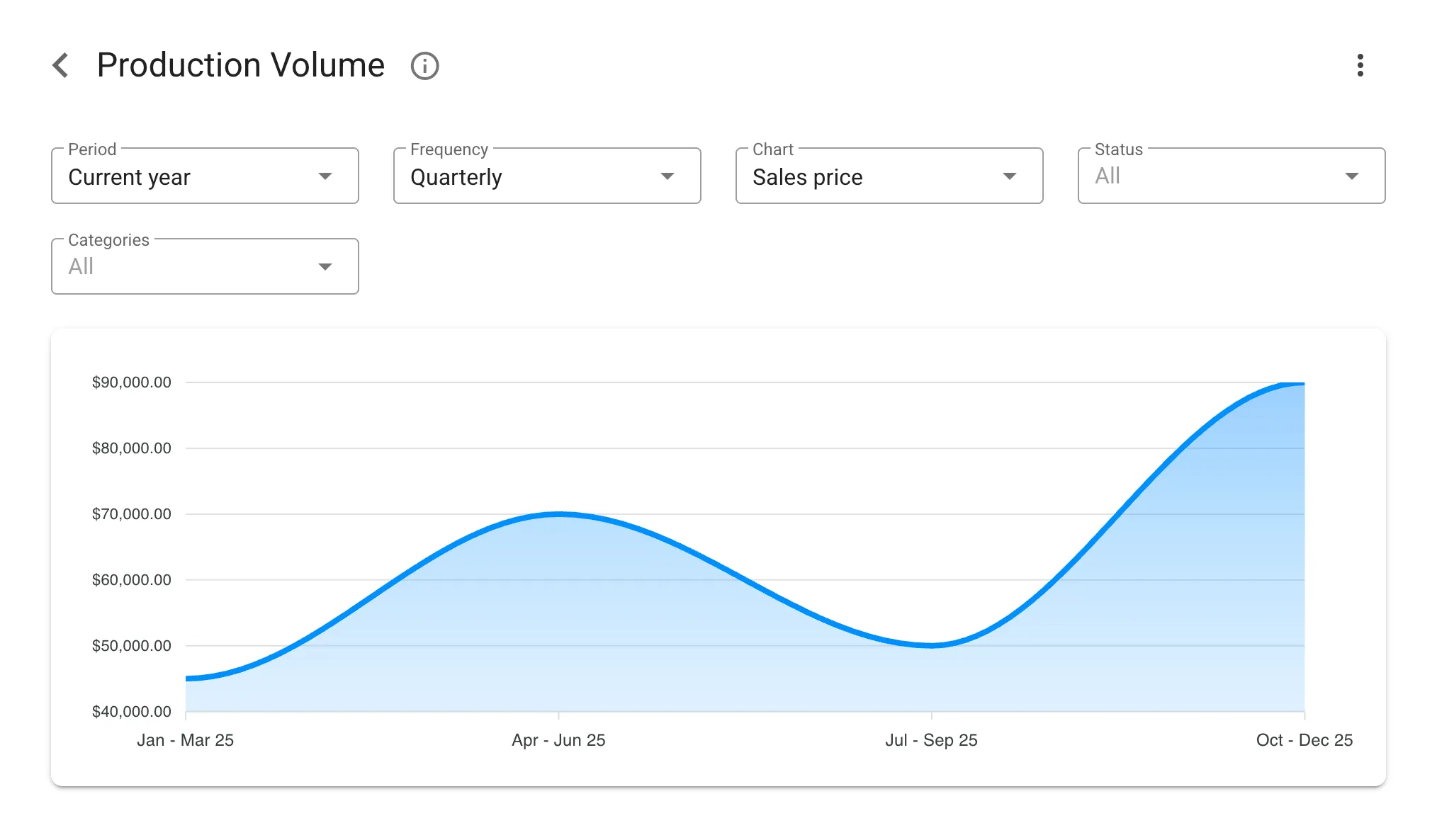

Performance Analytics

Analyze manufacturing operations performance with detailed reporting and analytics. Track KPIs, identify trends, and generate insights to continuously improve your manufacturing operations management processes.

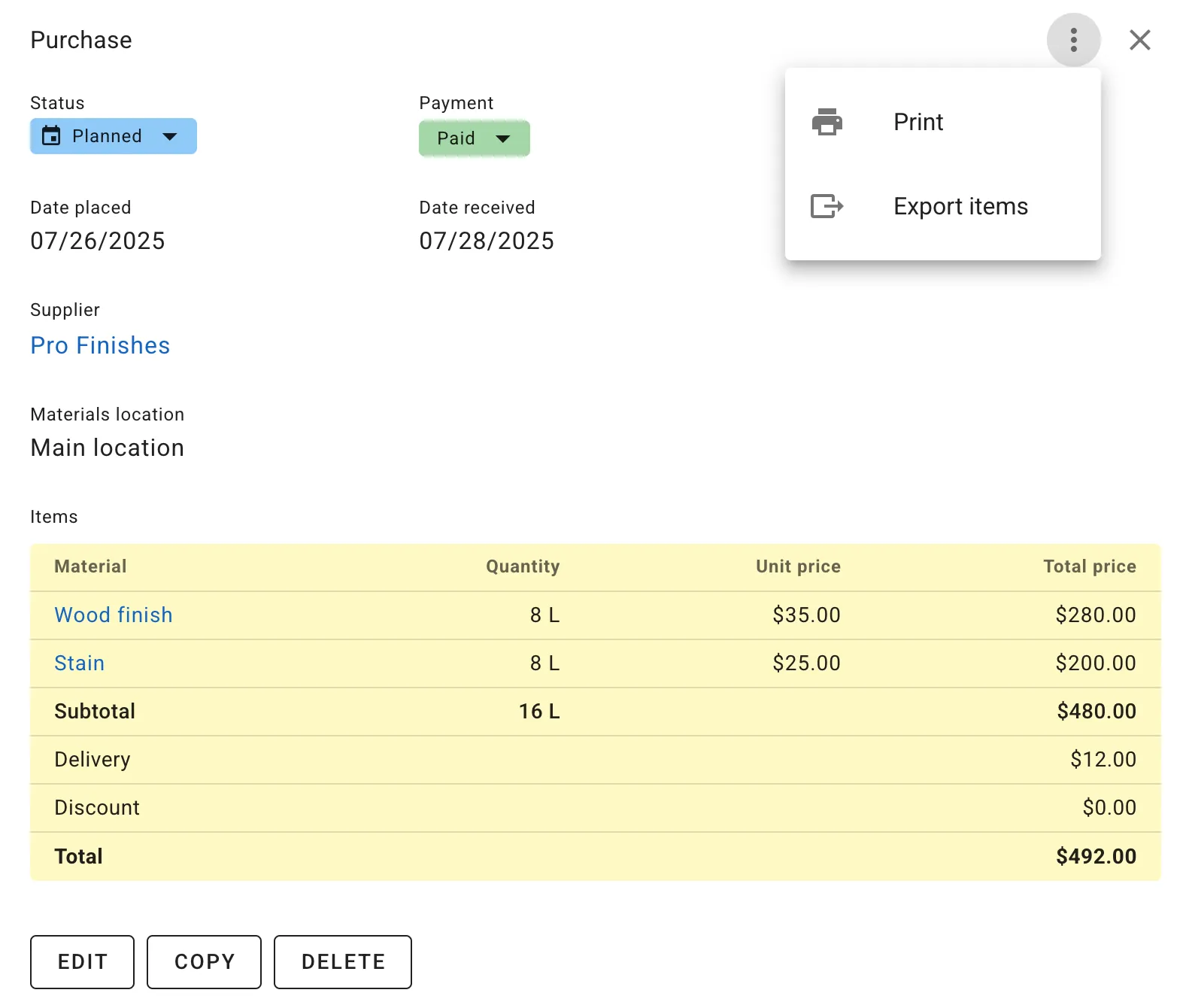

Purchase & Sales Management

Coordinate purchasing and sales activities within your manufacturing operations. Track supplier deliveries, manage customer orders, and ensure seamless coordination between procurement and production processes.

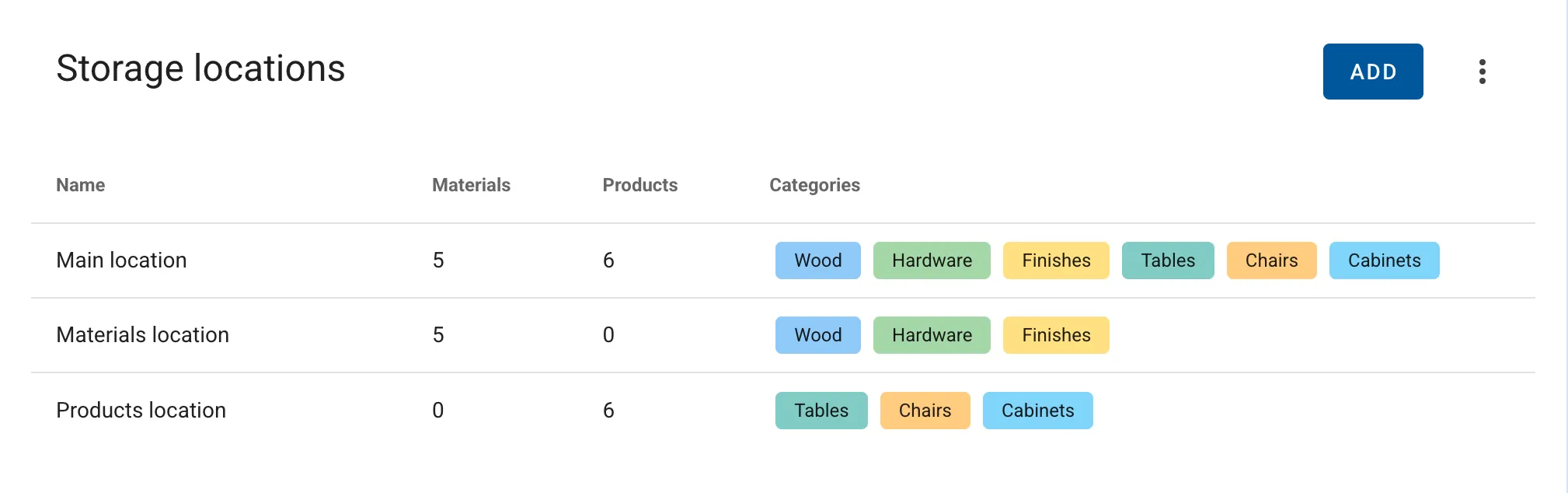

Multi-location Operations

Manage manufacturing operations across multiple facilities and locations. Coordinate production schedules, transfer materials between sites, and maintain visibility across your entire manufacturing network.

Optimize Manufacturing Operations for Maximum Efficiency

Revolutionize your manufacturing operations management with Controlata's powerful platform. Our software helps you:

Increase Operational Efficiency

Streamline manufacturing operations with automated workflows and optimized scheduling. Eliminate bottlenecks and reduce cycle times across all production processes.

Reduce Manufacturing Costs

Lower operational costs through improved resource utilization and waste reduction. Optimize material usage, minimize downtime, and maximize return on manufacturing investments.

Enhance Production Control

Maintain tight control over your manufacturing operations with real-time monitoring and automated material tracking. Ensure consistent production quality and process adherence.

Improve Production Visibility

Gain complete visibility into your manufacturing operations with real-time monitoring and comprehensive reporting. Make informed decisions based on accurate operational data.

Accelerate Decision Making

Enable faster decision-making with real-time insights and automated alerts. Respond quickly to operational changes and maintain optimal manufacturing performance.

Optimize Resource Allocation

Maximize the efficiency of equipment, materials, and workforce through intelligent resource allocation and utilization tracking across all manufacturing operations.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.