Manufacturing Scheduling Software

Controlata is an advanced manufacturing scheduling software designed to optimize production workflows and resource allocation. Create detailed schedules, manage production capacity, and ensure on-time delivery with our intelligent scheduling system.

Advanced Manufacturing Scheduling Features

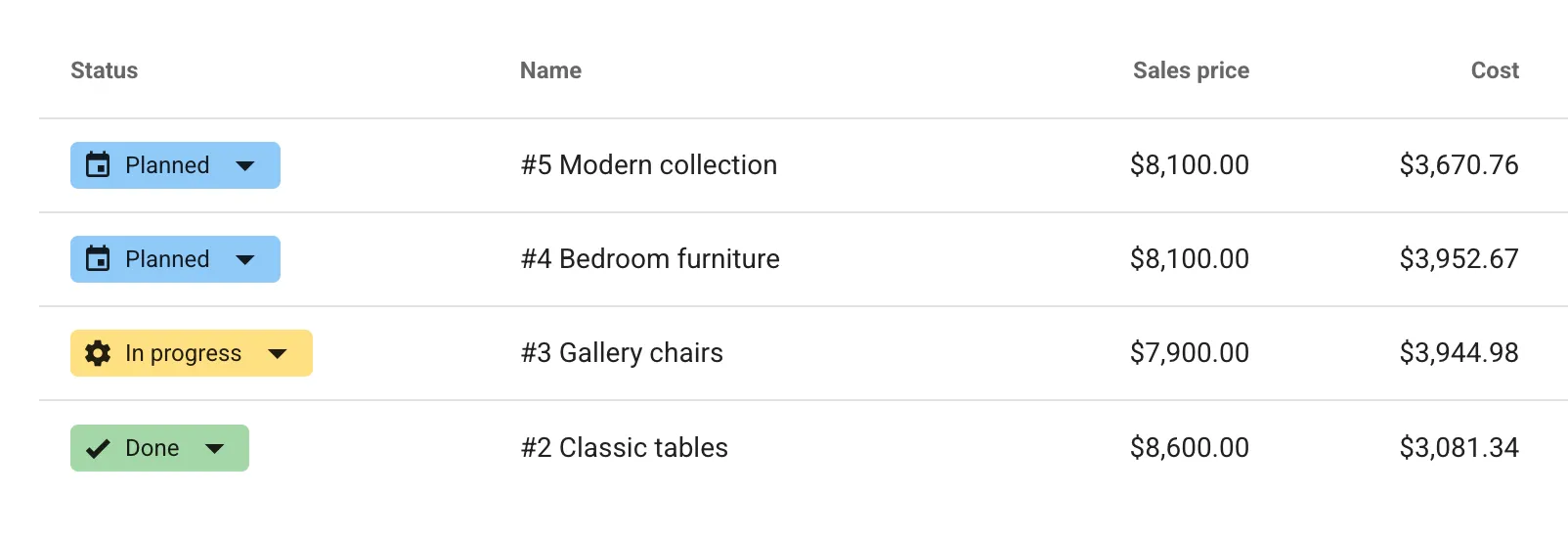

Production Schedule Management

Create and manage detailed production schedules with intuitive planning tools. Visualize your entire production timeline, track order progress, and monitor manufacturing status in real-time for optimal workflow coordination.

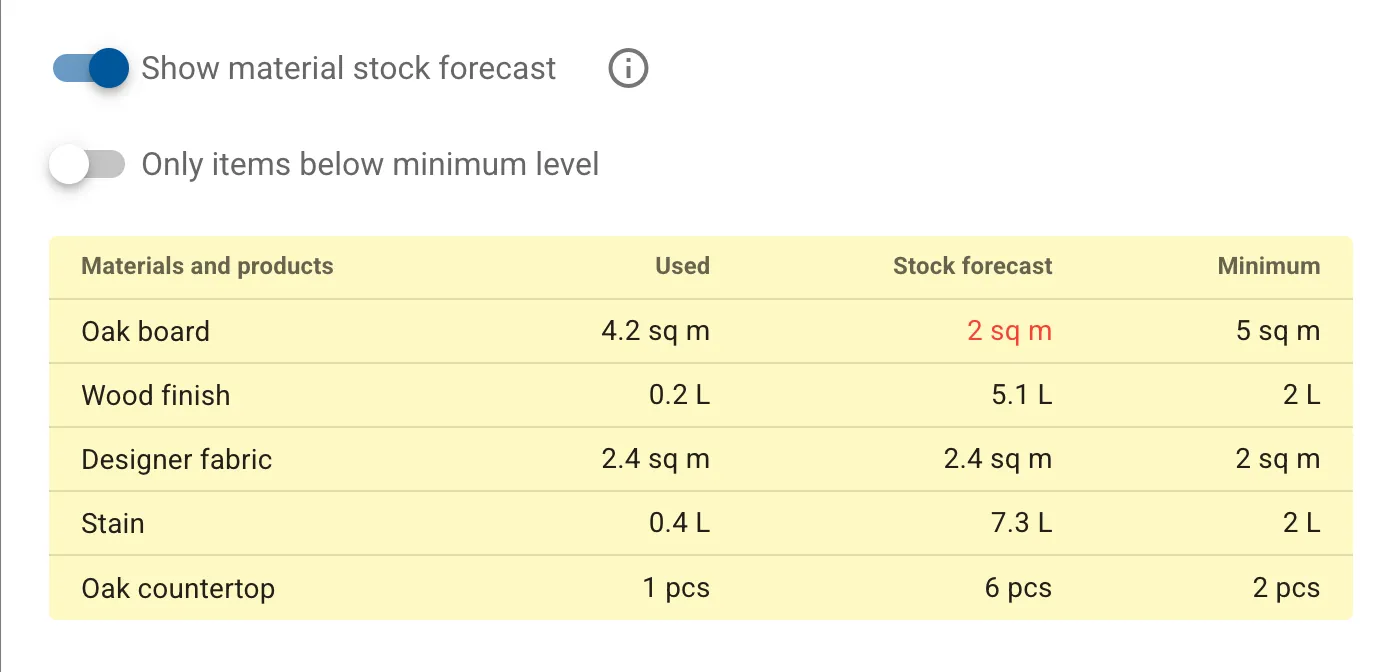

Material Requirements Scheduling

Ensure material availability for scheduled production runs. Automatically calculate material requirements based on production plans, check inventory levels, and coordinate procurement schedules to prevent production delays.

Production Status Tracking

Monitor production progress with customizable status workflows. Track orders from planning through completion, update status in real-time, and maintain visibility across your entire manufacturing operation.

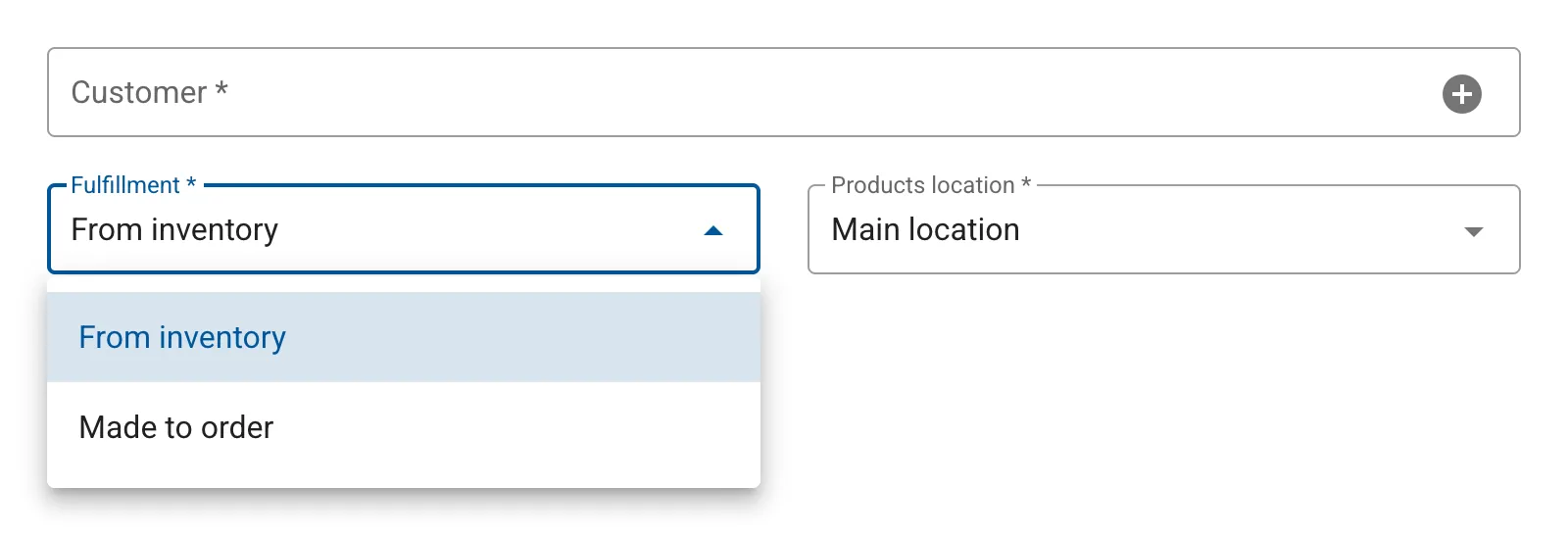

Make-to-Order vs Make-to-Stock Scheduling

Flexibly schedule production for both inventory building and customer-specific orders. Balance stock replenishment with custom order fulfillment to optimize inventory levels and customer satisfaction.

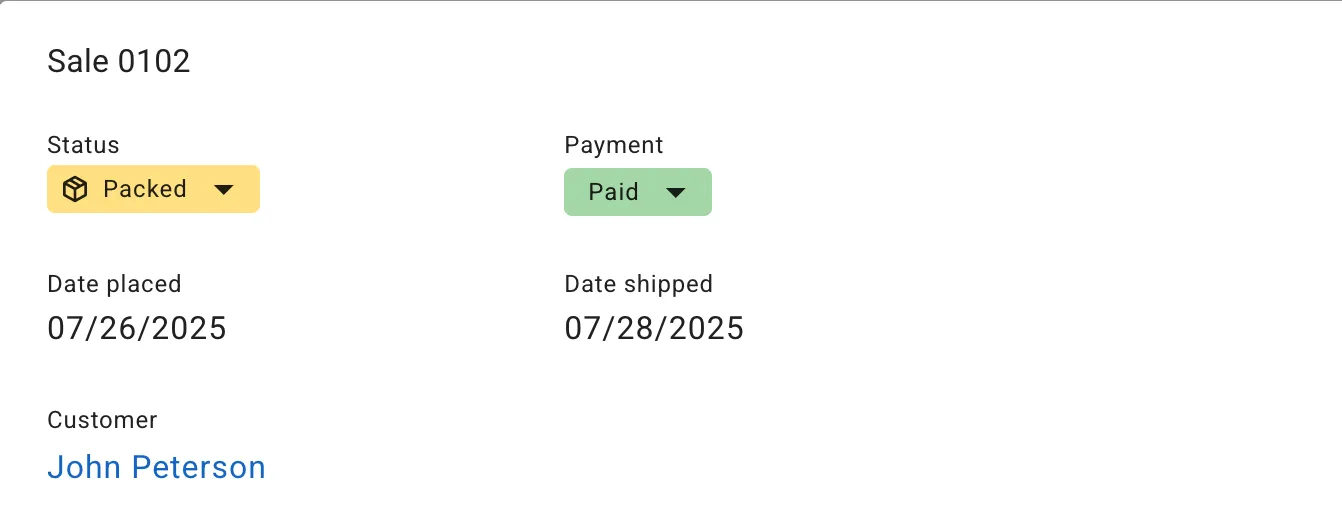

Delivery Date Management

Track and manage delivery commitments with precision. Monitor order progress against scheduled completion dates, identify potential delays early, and take proactive measures to ensure on-time delivery.

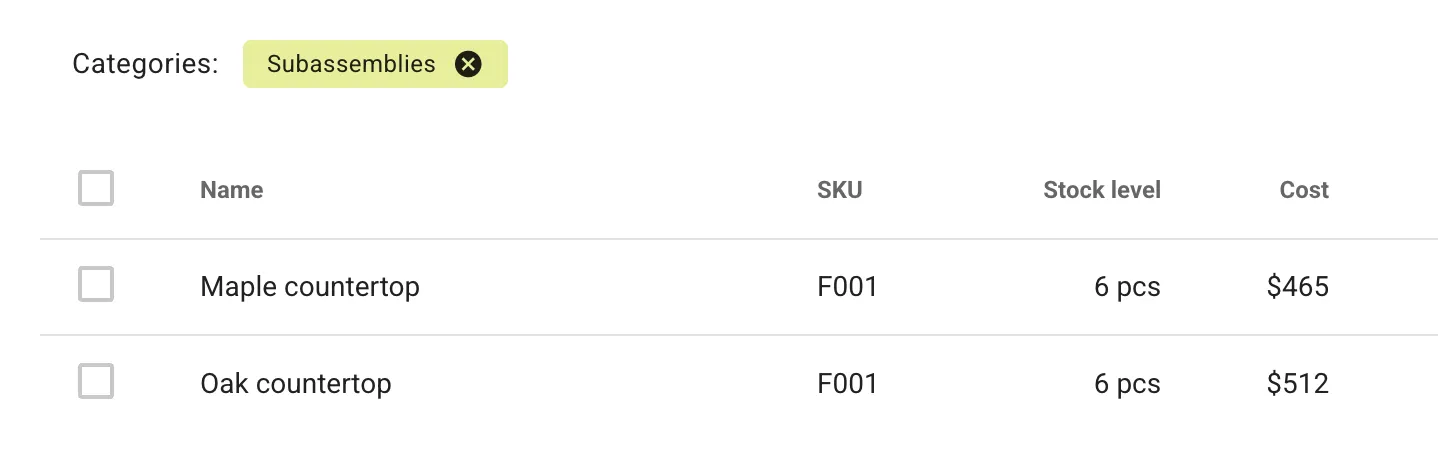

Multi-level Production Scheduling

Schedule complex products with sub-assemblies and components. Coordinate dependent manufacturing processes, manage work-in-progress flow between levels, and maintain visibility across multi-tier production.

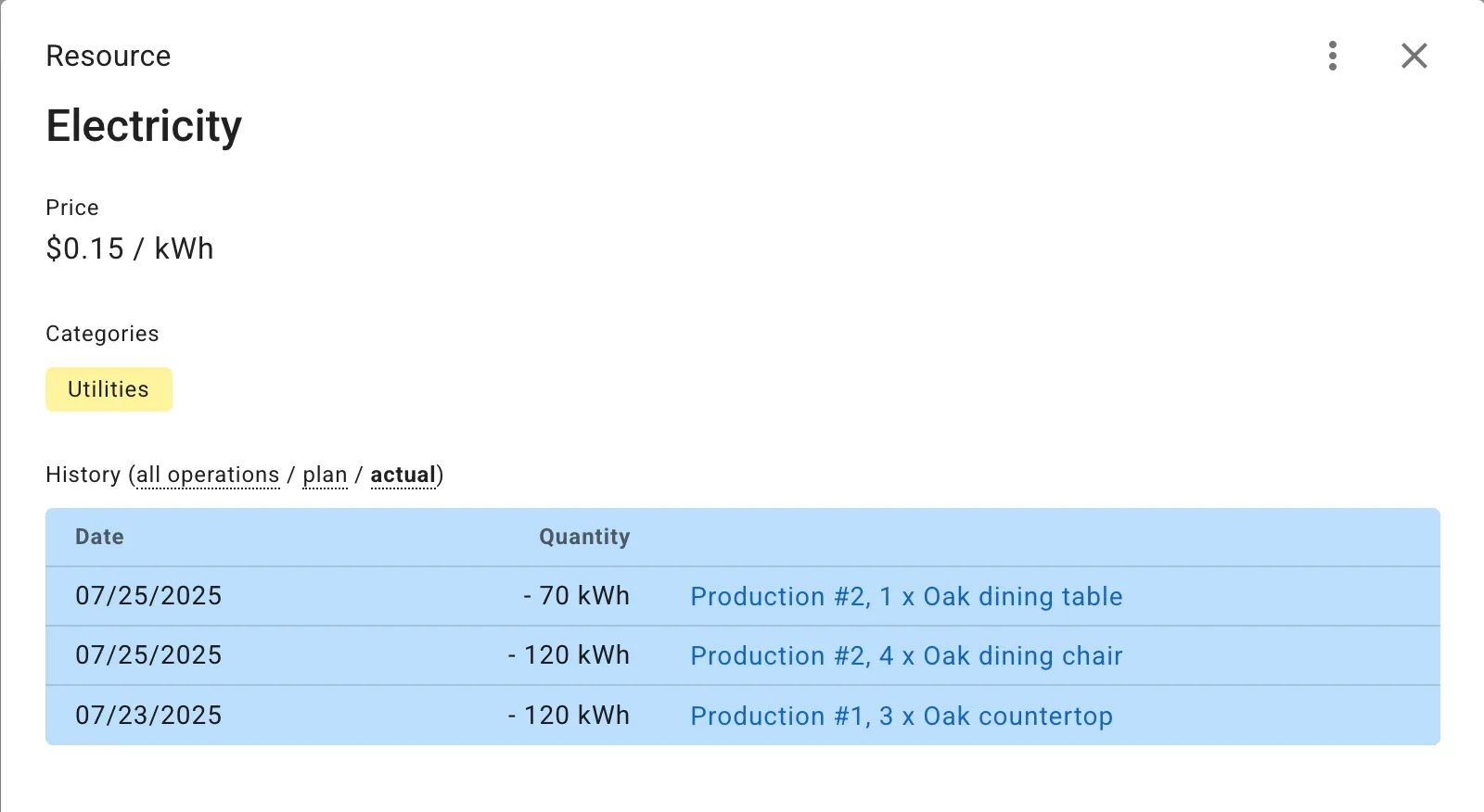

Resource Cost Scheduling

Plan and schedule resource costs including labor, equipment depreciation, and overhead expenses. Calculate resource requirements for scheduled production and forecast manufacturing costs accurately.

Streamline Your Manufacturing Operations

Transform your production scheduling with Controlata's intelligent software. Our solution delivers:

Precise Schedule Control

Create accurate production schedules that account for all constraints. Balance customer demands with resource availability to deliver orders on time, every time.

Increased Production Efficiency

Maximize throughput with optimized material planning and resource utilization. Reduce setup times, minimize delays, and boost overall equipment effectiveness.

Seamless Workflow Coordination

Synchronize all production activities for smooth operations. Coordinate material flow, labor assignments, and equipment usage to eliminate bottlenecks.

Real-time Progress Tracking

Monitor production progress against schedules in real-time. Quickly identify deviations and take corrective action to keep projects on track.

On-time Delivery Achievement

Meet customer delivery commitments consistently. Advanced scheduling algorithms ensure realistic timelines and proactive delay management.

Performance Analytics

Analyze schedule performance and identify improvement opportunities. Track key metrics like on-time delivery rates, resource utilization, and cycle times.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.