MRP System for Manufacturing

Optimize inventory levels, plan material requirements, and automate production needs calculation. Implement a modern manufacturing resource planning system today!

System Capabilities

All essential tools for material management and procurement planning in one solution

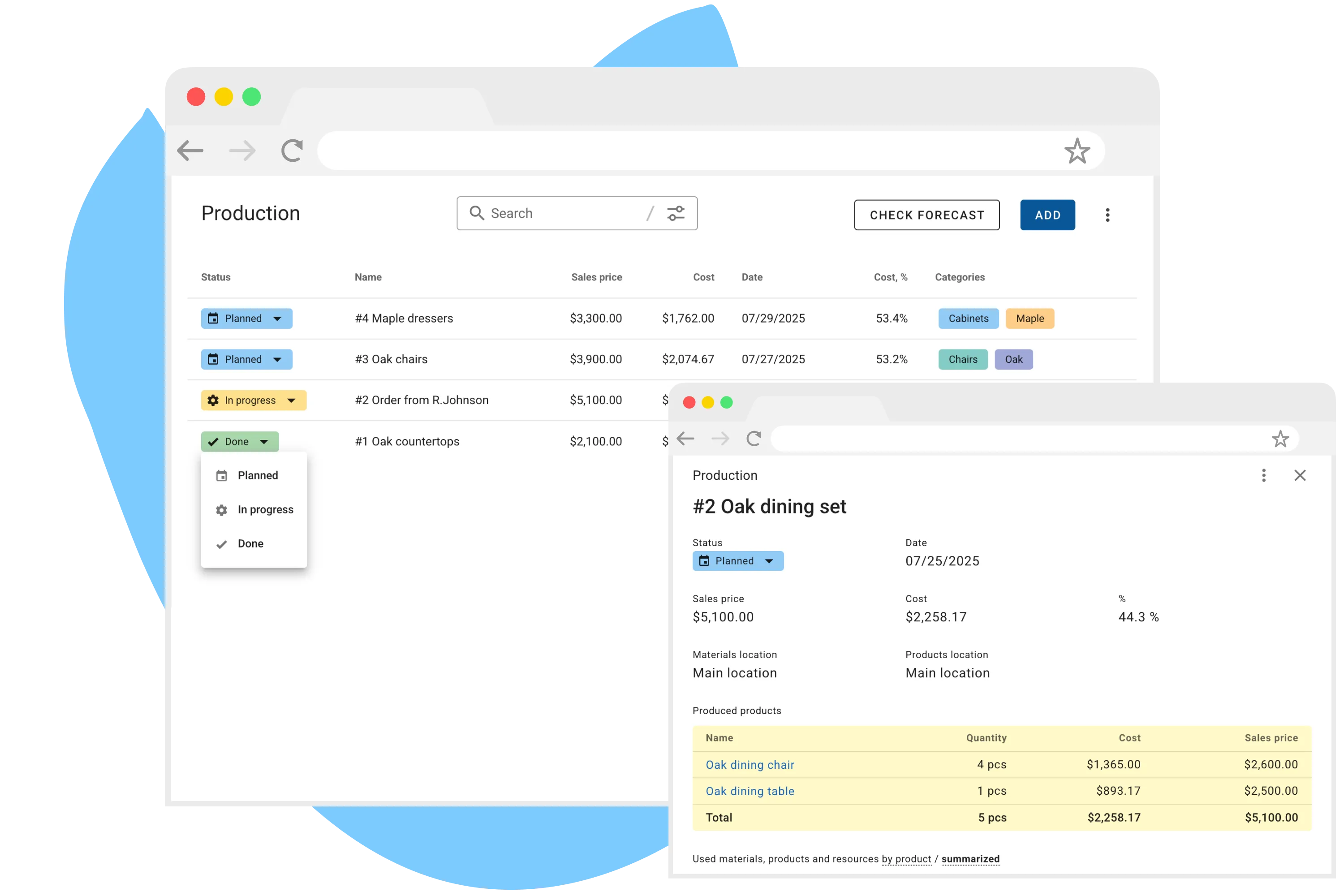

Requirements Planning

Automatically calculate material requirements based on production schedules and product specifications. The system accounts for current inventory levels and already placed orders.

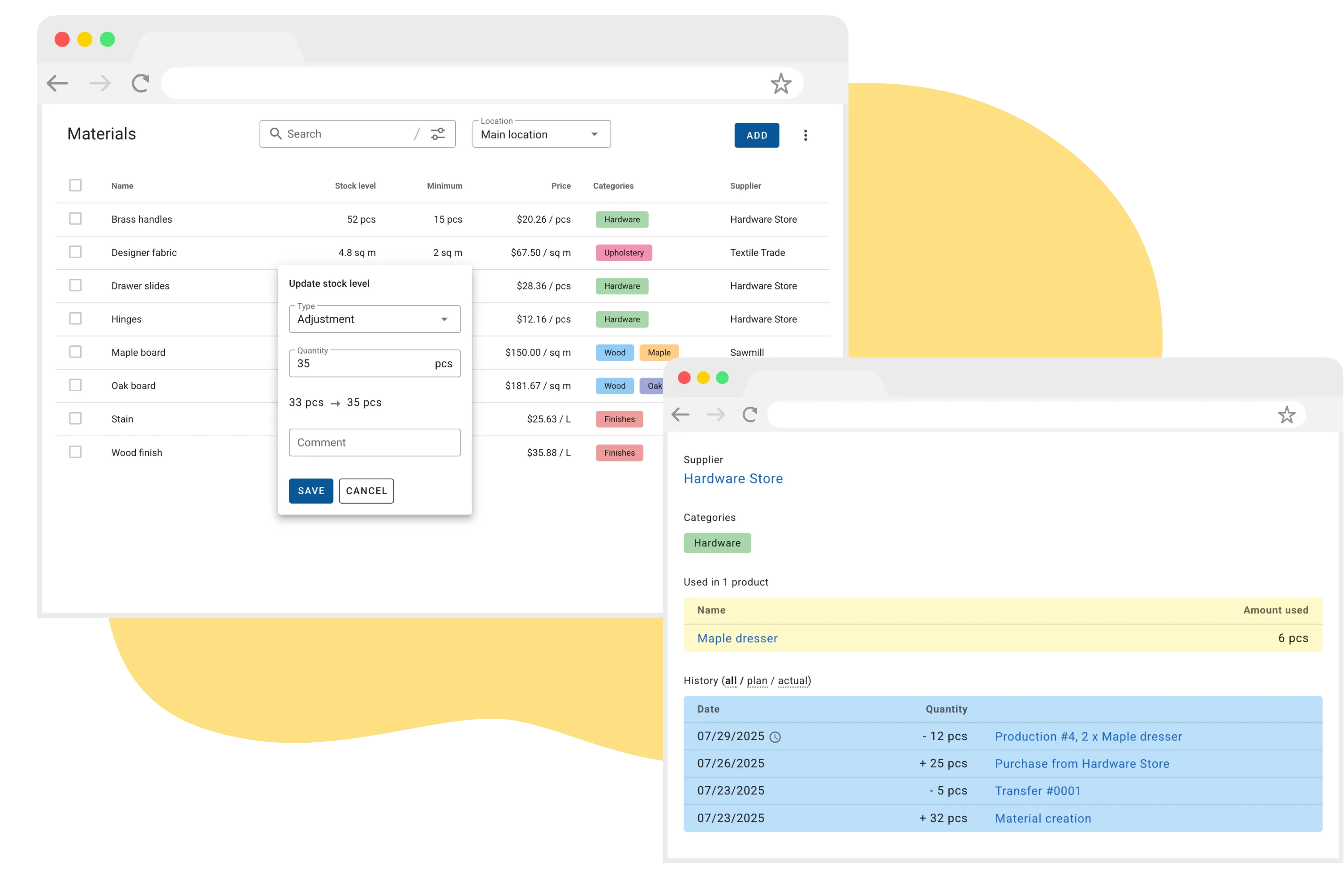

Inventory Management

Optimize warehouse stock levels: the system calculates the optimal order quantity and reorder point for each material, considering delivery times and production needs.

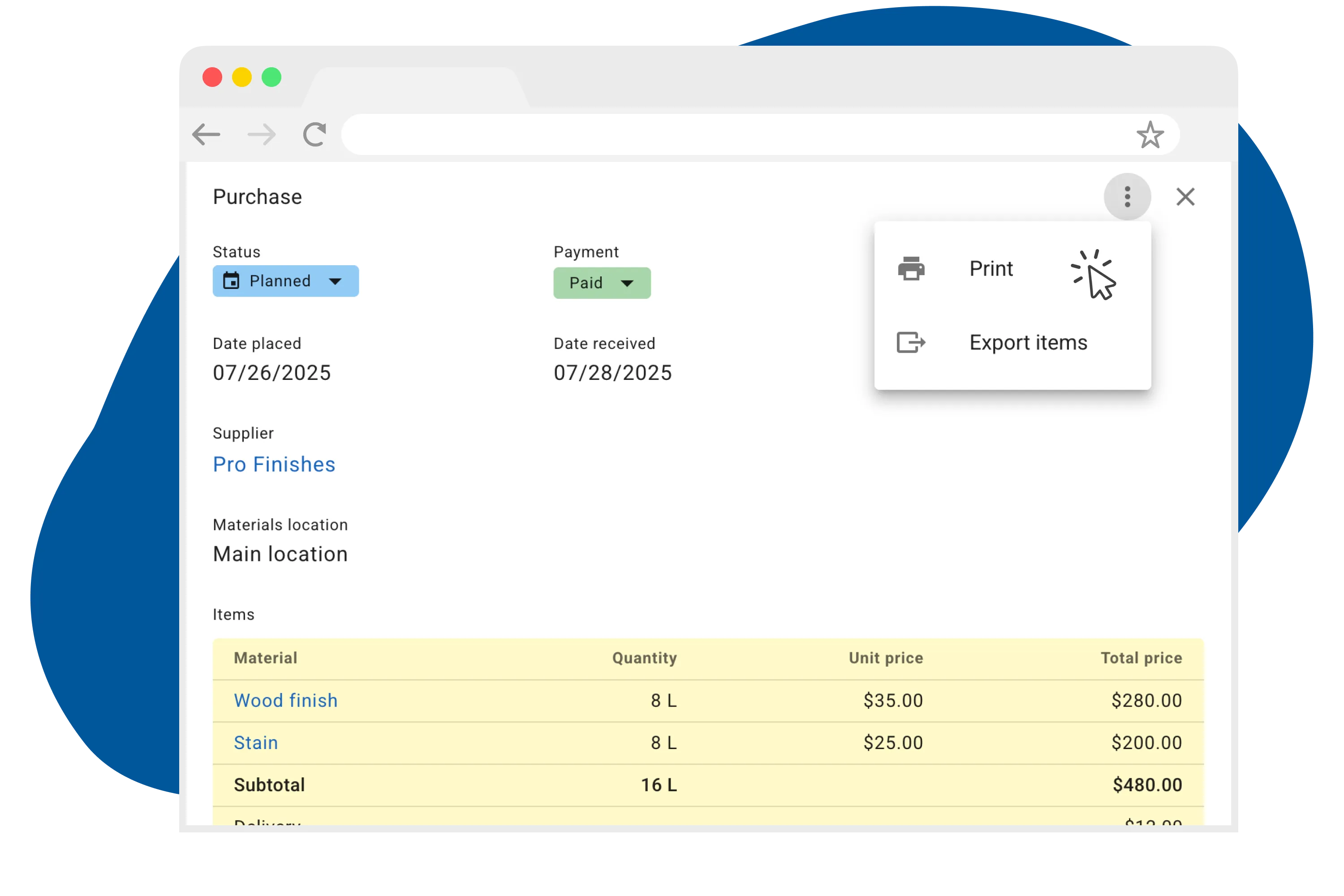

Procurement Control

Automate the purchasing process: from requisition creation to material receipt. The system tracks delivery timelines and alerts you to potential delays.

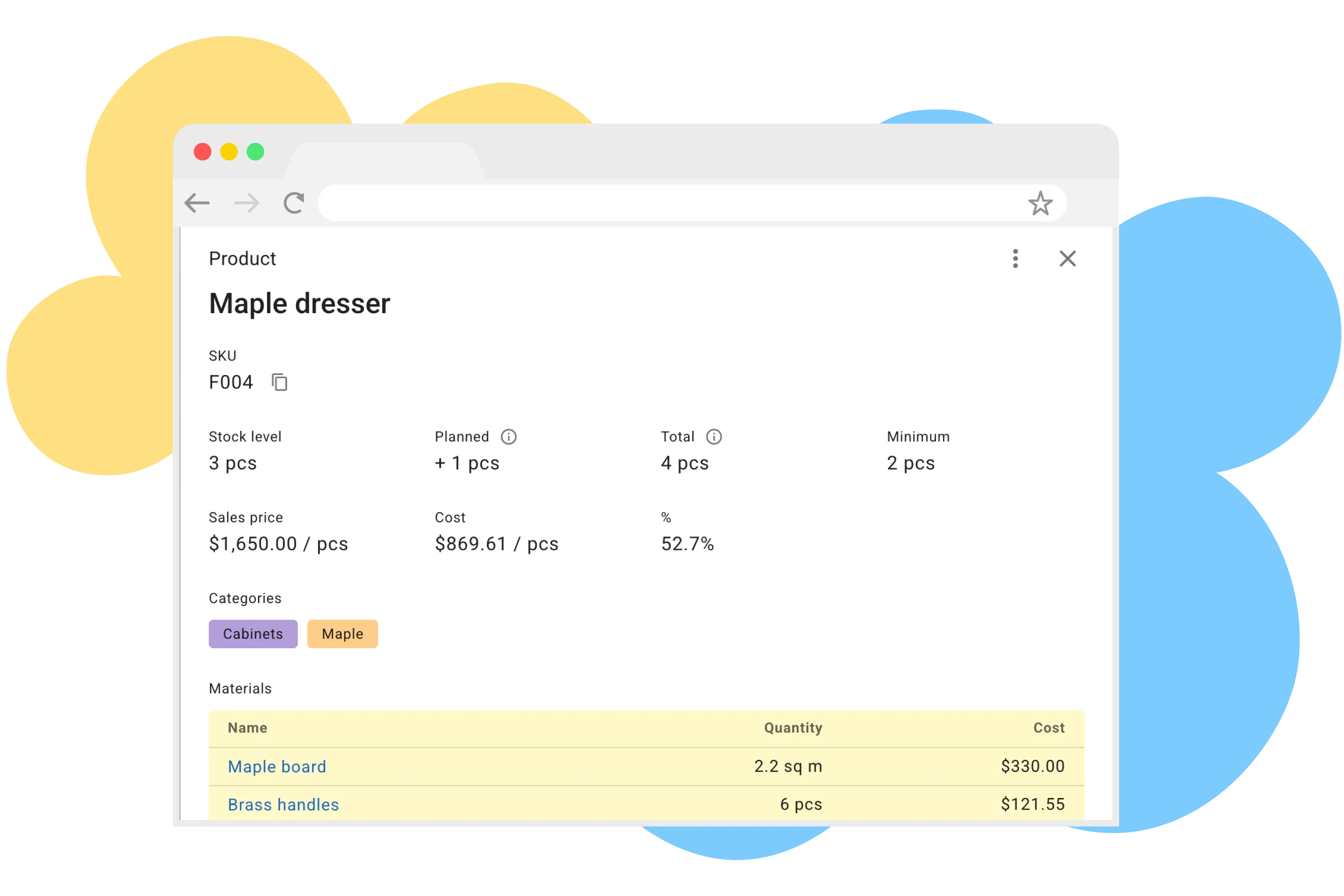

Bill of Materials

Maintain a database of specifications: product components, material consumption norms, and production routes. The system automatically calculates material requirements for each order.

Warehouse Tracking

Monitor material movement in real-time. The system automatically updates inventory levels when materials are received and released to production.

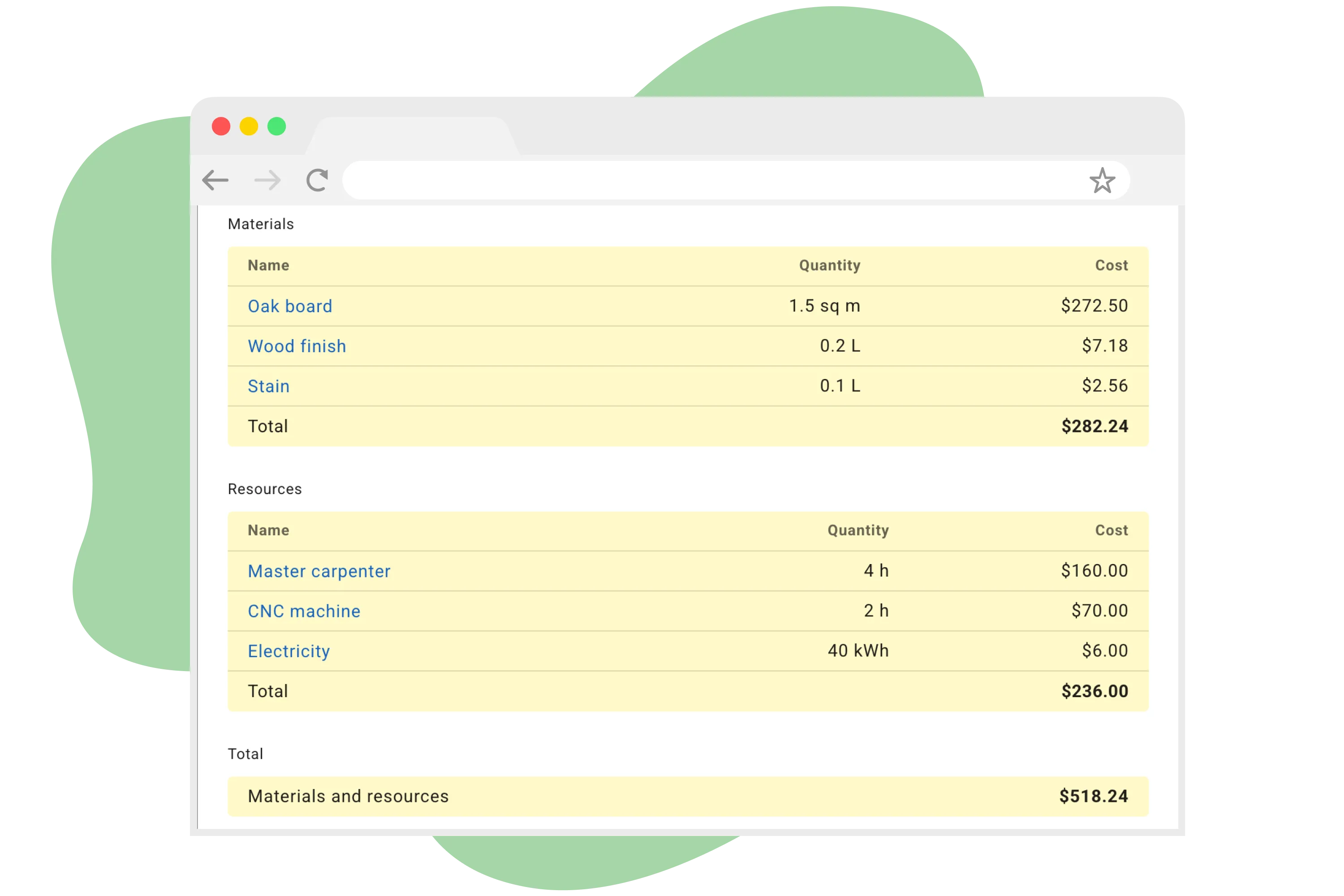

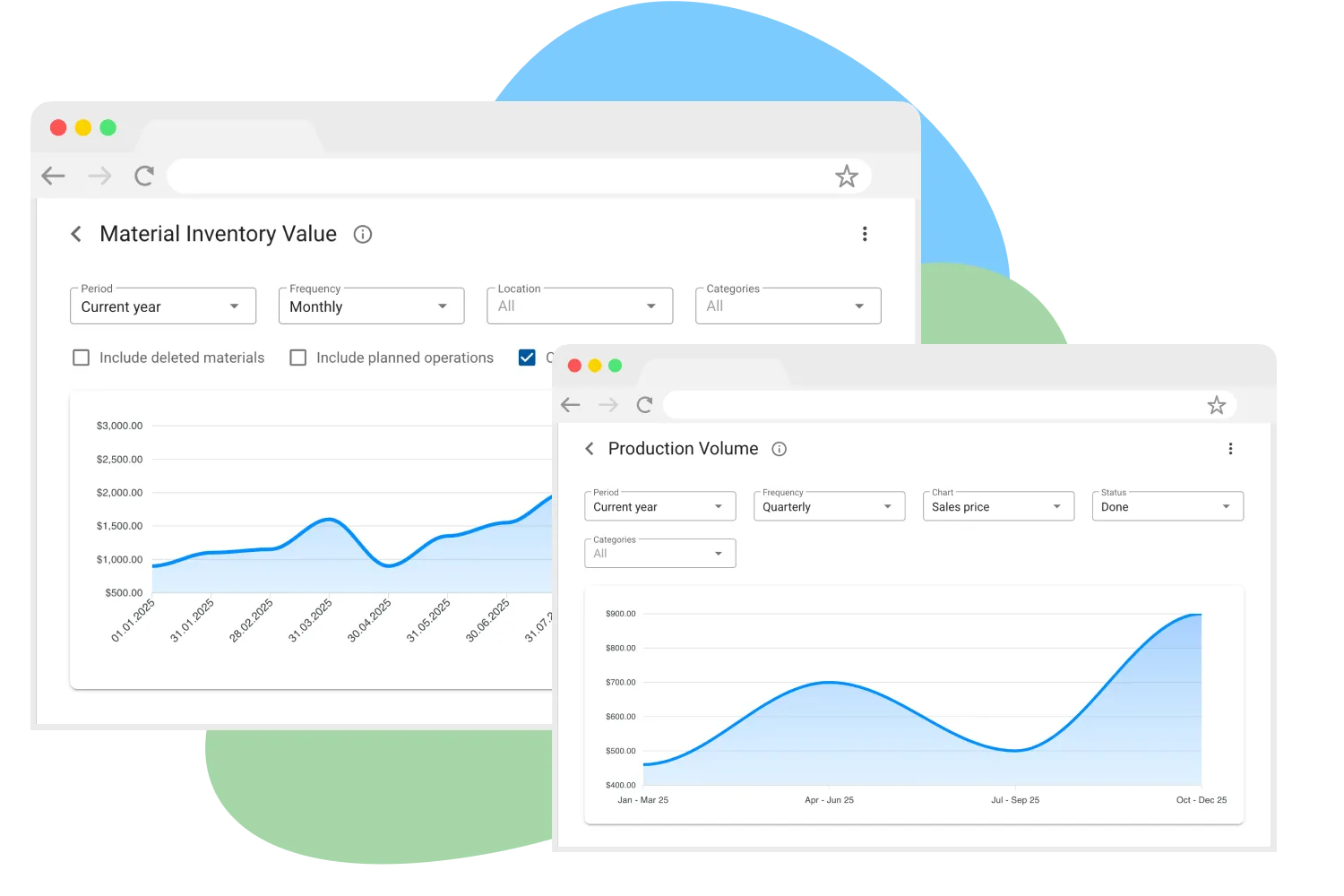

Analytics and Reports

Analyze inventory management efficiency with built-in reports. Track key performance indicators: inventory turnover, material shortages, and planning accuracy.

Controlata Advantages

A modern MRP software created for real manufacturing challenges

Inventory Optimization

Reduce warehouse stock through precise procurement planning. The system helps you balance storage costs and shortage risks.

Routine Automation

The system automatically calculates material requirements and creates purchasing schedules. Save time on planning and reduce errors.

Just-in-Time Delivery

Minimize production halts due to material shortages. The system considers delivery lead times and safety stock when planning.

Easy Onboarding

Intuitive interface allows you to start working without extensive training. Access the system from any browser.

Responsive Support

Quick answers to questions from system developers in chat. We help customize the system to fit your business processes.

Affordable Pricing

Transparent pricing system with no hidden fees. Quick ROI through reduced inventory costs.

Frequently Asked Questions

Answers to key questions about implementing and working with our MRP system

What is an MRP system?

How long does implementation take?

How do I transfer material data?

How are material requirements calculated?

Will the system help reduce inventory?

Can I set up access permissions?