Production Management Software

Controlata is a comprehensive production management software that provides complete control over manufacturing processes, cost tracking, and operational transparency. Gain full visibility into production operations and enhance manufacturing efficiency.

Comprehensive Production Management Features

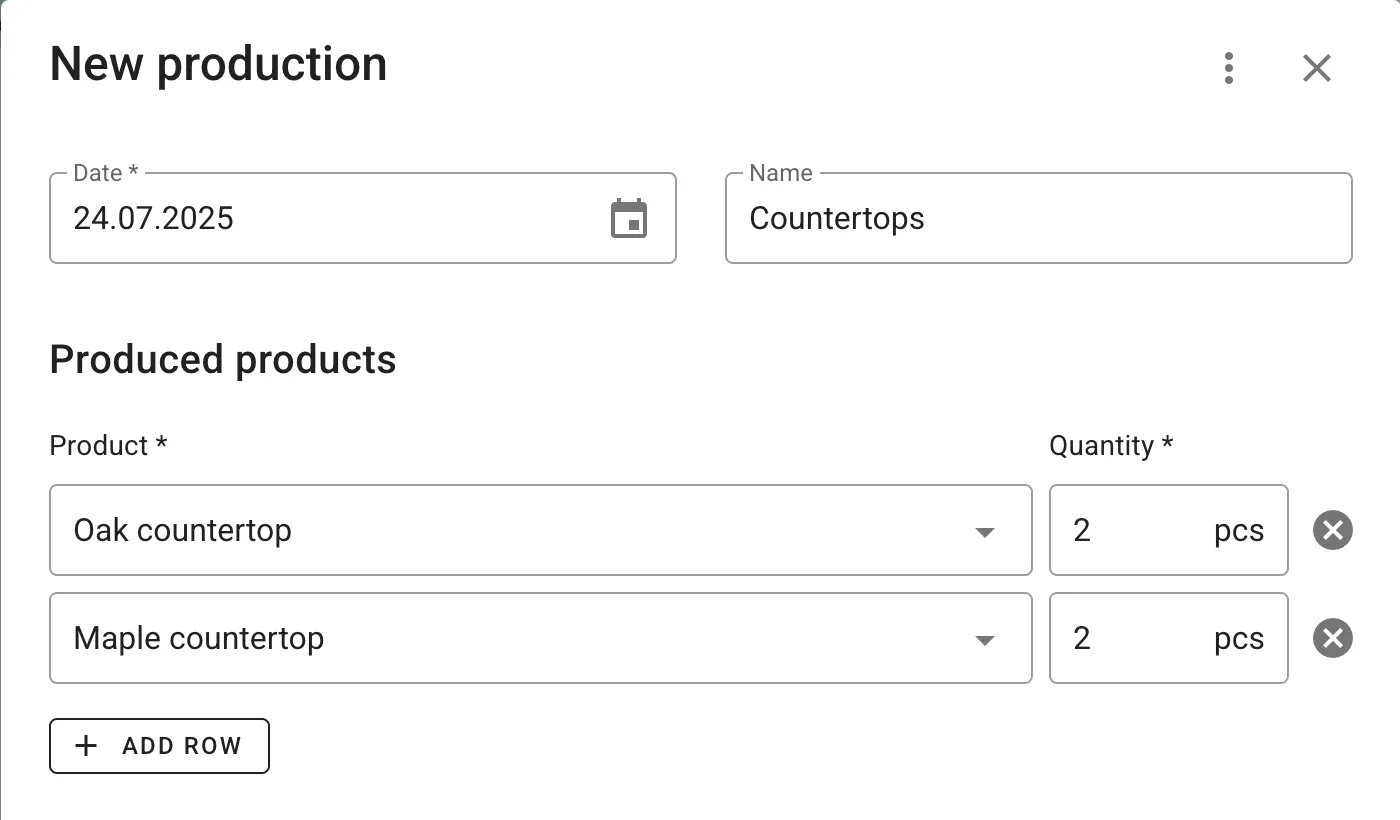

Manufacturing Process Control

Monitor all production stages in real-time. Control the execution of manufacturing tasks, technology compliance, and product manufacturing timelines throughout your production facility.

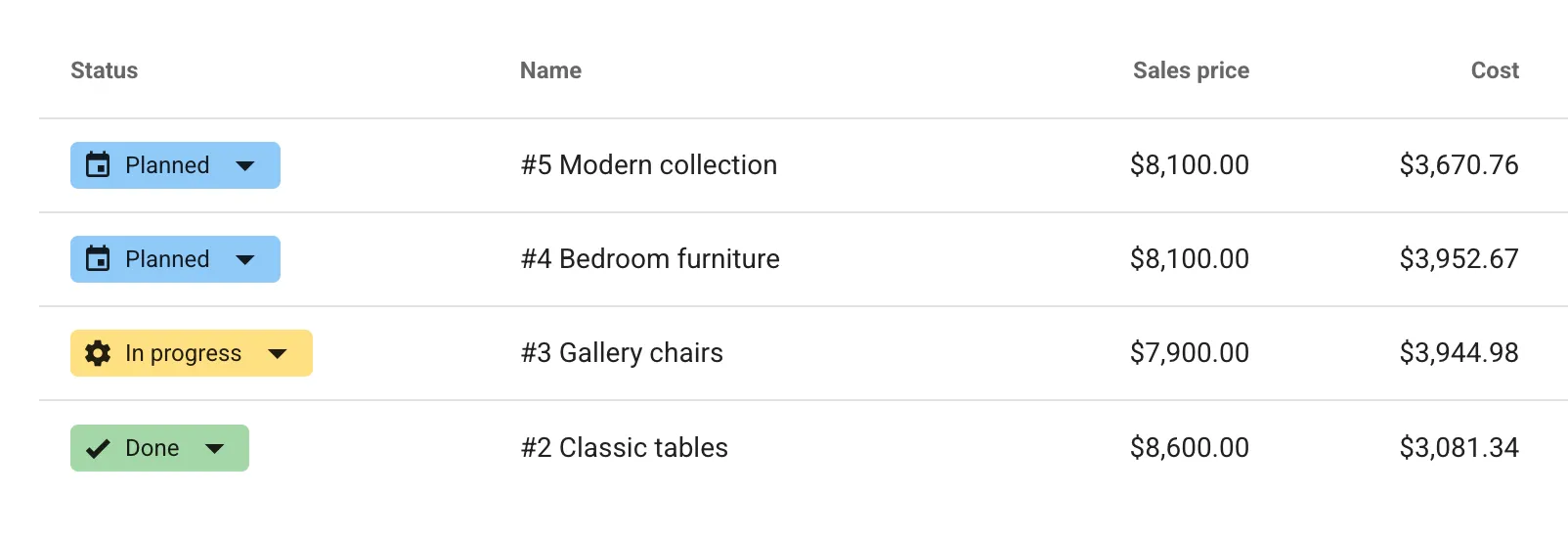

Production Status Management

Create production statuses tailored to your manufacturing specifics and track order movement through stages. Get a complete picture of each order's status within the production cycle.

Operations Management

Efficiently organize the execution of production operations and tasks. Distribute work between departments, control operation sequences, and ensure coordinated production workflow.

Work in Progress Control

Maintain precise tracking of work in progress across all departments. Control WIP volumes and costs to optimize working capital and identify issues promptly.

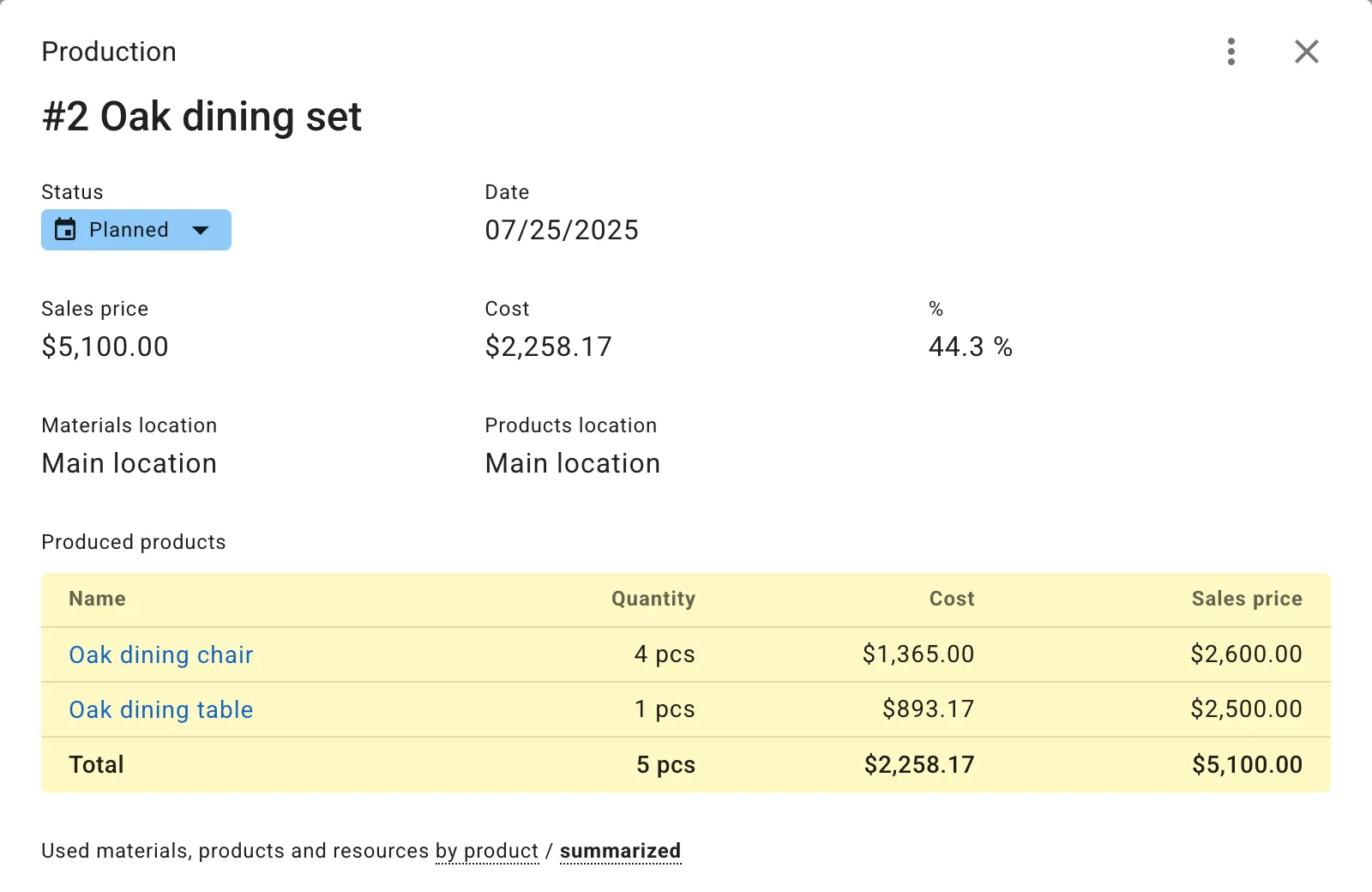

Production Cost Management

Monitor all production costs in real-time. Analyze product cost of goods sold and identify opportunities for expense optimization and margin improvement.

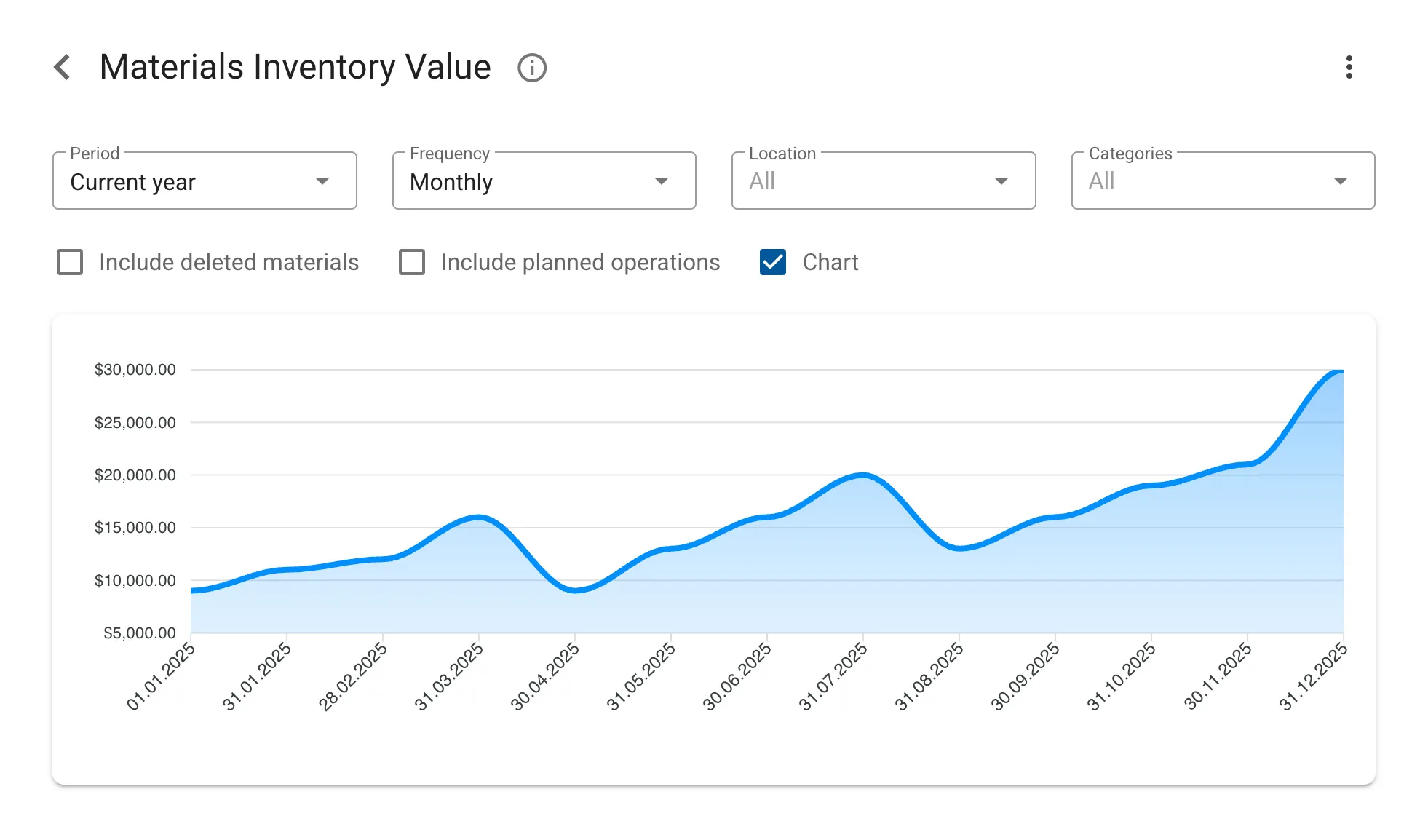

Production Reporting and Analytics

Generate detailed production reports, analyze KPIs and process efficiency. Make informed management decisions based on current data and comprehensive analytics.

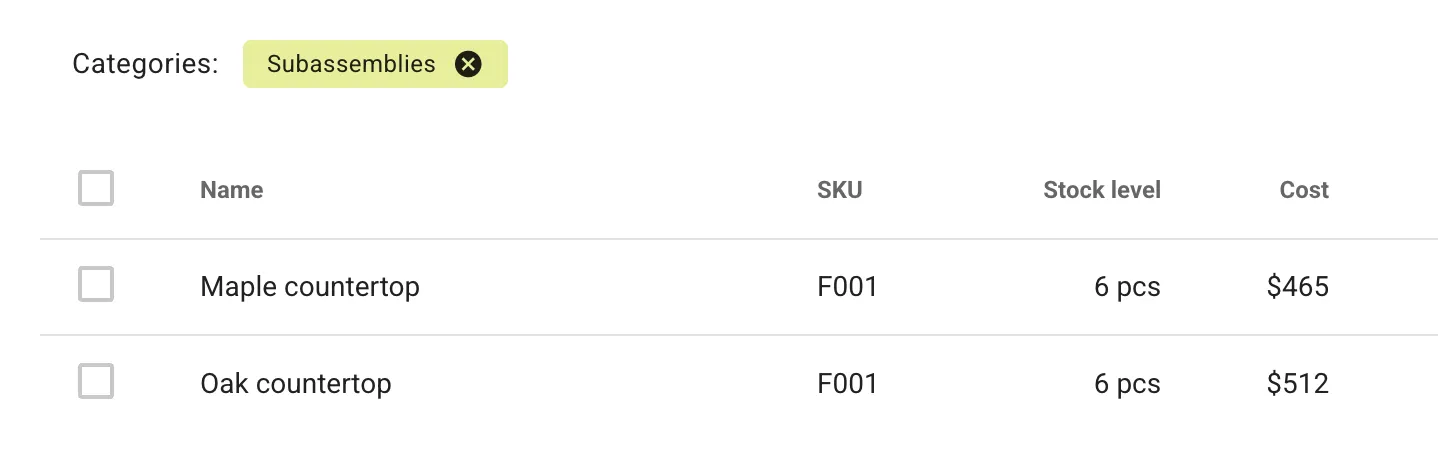

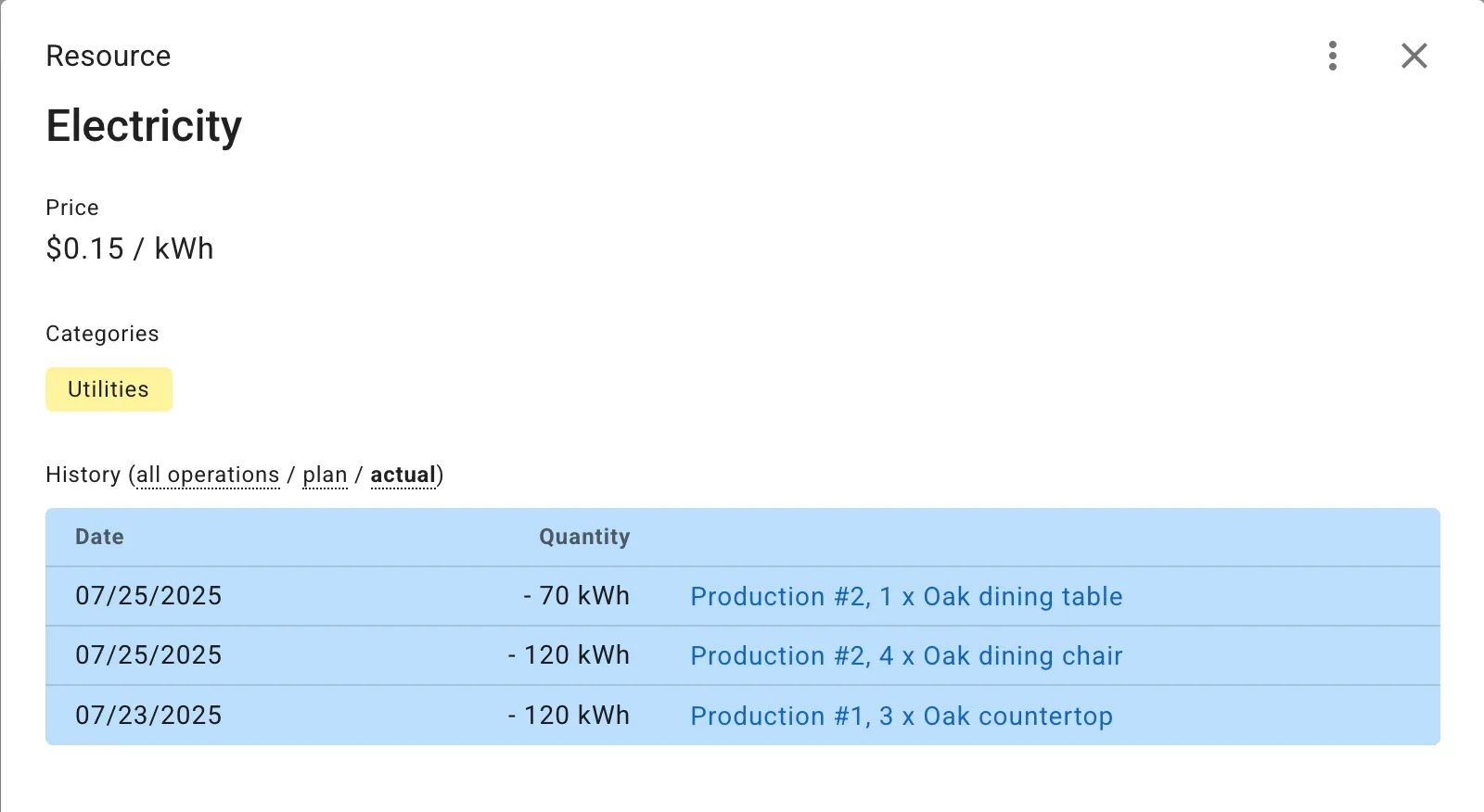

Production Resource Management

Control material consumption, labor costs, equipment depreciation, and overhead expenses. Track actual resource usage and analyze deviations from planned performance indicators.

Transform Your Production Management

Implementing Controlata production management software provides:

Complete Production Transparency

Access real-time information about all manufacturing processes. Monitor task execution and respond promptly to deviations from planned operations.

Production Process Control

Track compliance with technological processes and execution of manufacturing tasks at all stages. Ensure stability and reliability of production operations.

Reduced Production Costs

Identify and eliminate inefficient processes, reduce material waste and labor time losses. Optimize product cost through precise cost tracking and analysis.

Workflow Optimization

Streamline production operations and eliminate bottlenecks in processes. Increase work efficiency through improved production organization.

Production Timeline Compliance

Control the execution of manufacturing tasks within established deadlines. Prevent delays and ensure timely delivery of finished products to customers.

Enhanced Production Efficiency

Optimize production processes and resource utilization. Increase productivity by eliminating bottlenecks and waste in manufacturing operations.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.