Production Planning Software

Controlata is a modern production planning software that automates production scheduling, material requirements calculation, and procurement planning. Meet delivery deadlines and optimize production processes with our intelligent planning system.

Powerful Production Planning Features

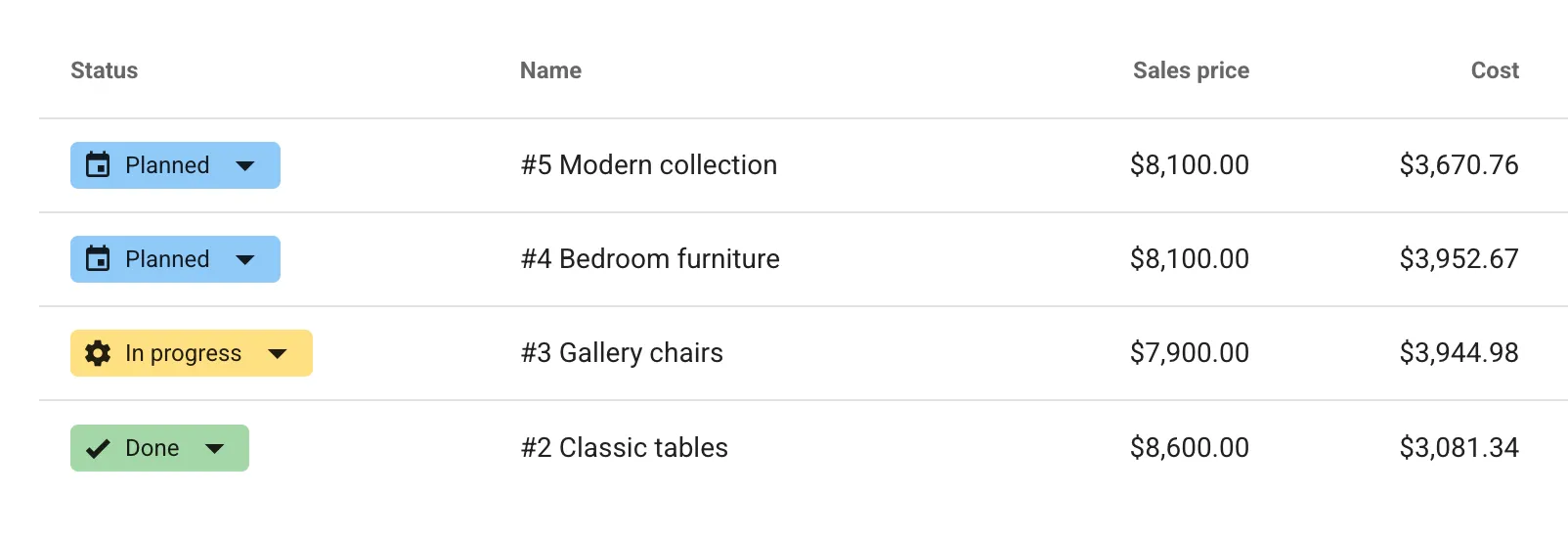

Production Scheduling

Create detailed production schedules for any period, considering customer orders and demand forecasts. Plan production volumes and manufacturing timelines for optimal operational efficiency.

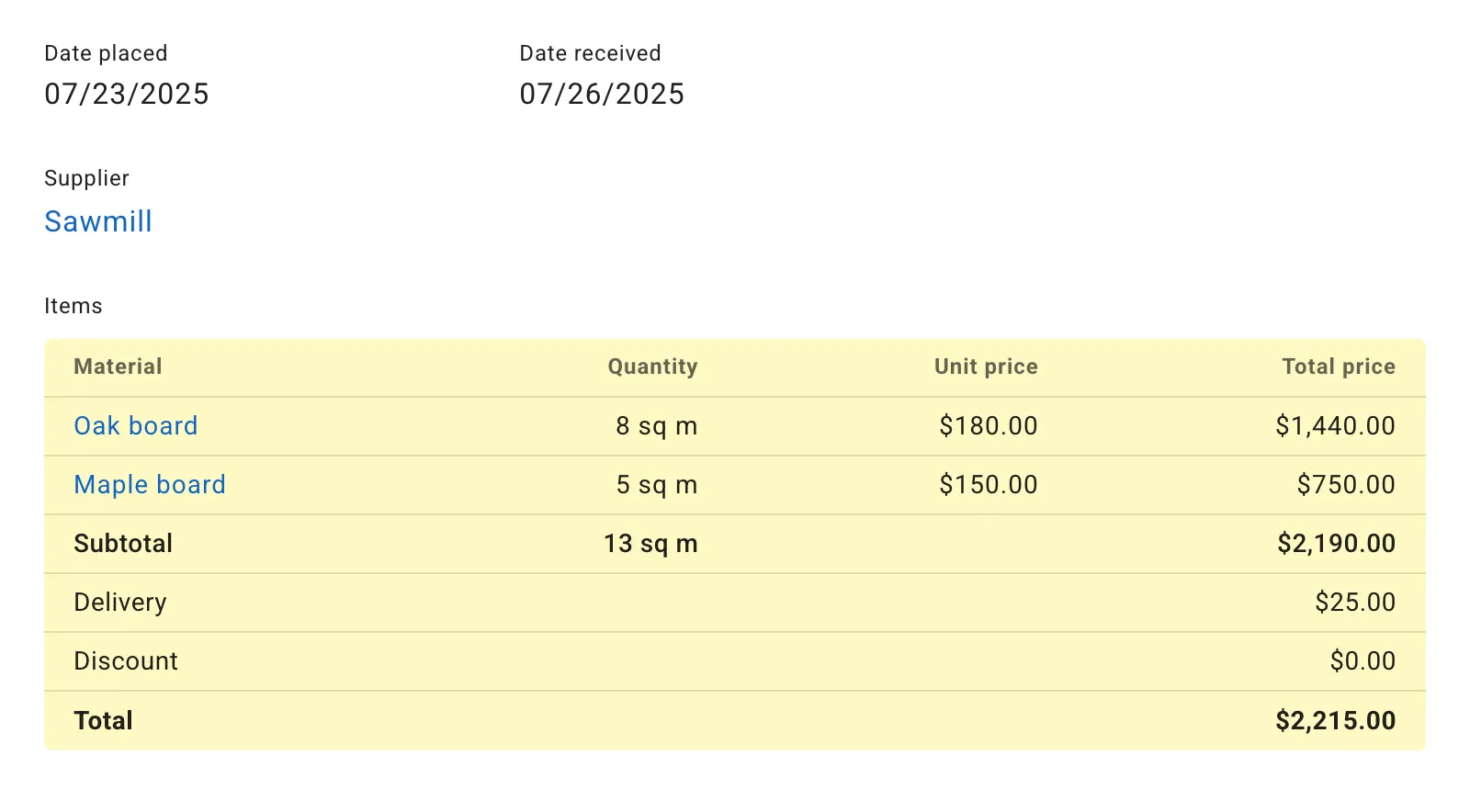

Procurement Planning

Automatically calculate material and component requirements based on production plans. Generate procurement schedules considering delivery lead times, minimum stock levels, and supplier order quantities.

Production Status Configuration

Create production process stages tailored to your manufacturing specifics. Configure any number of statuses and track order progress at each stage of your production cycle.

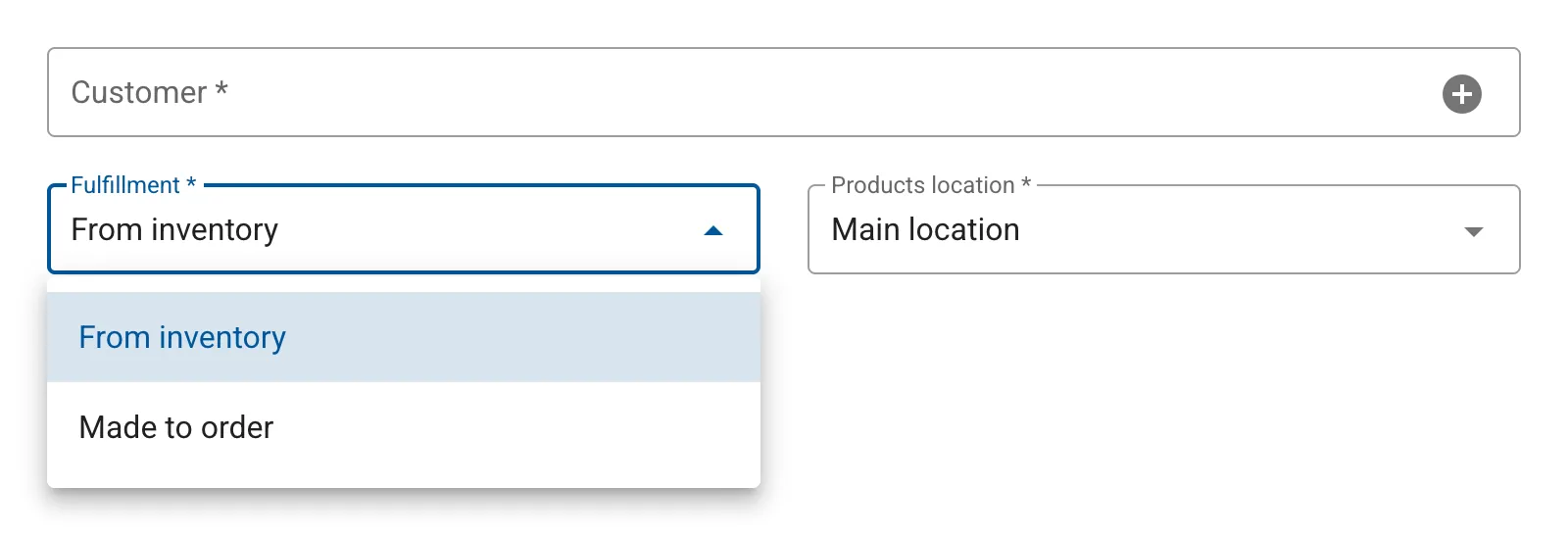

Production Strategy Planning

Flexibly plan production both for inventory (MTS) for popular items and for specific customer orders (MTO). Combine both approaches for maximum planning efficiency.

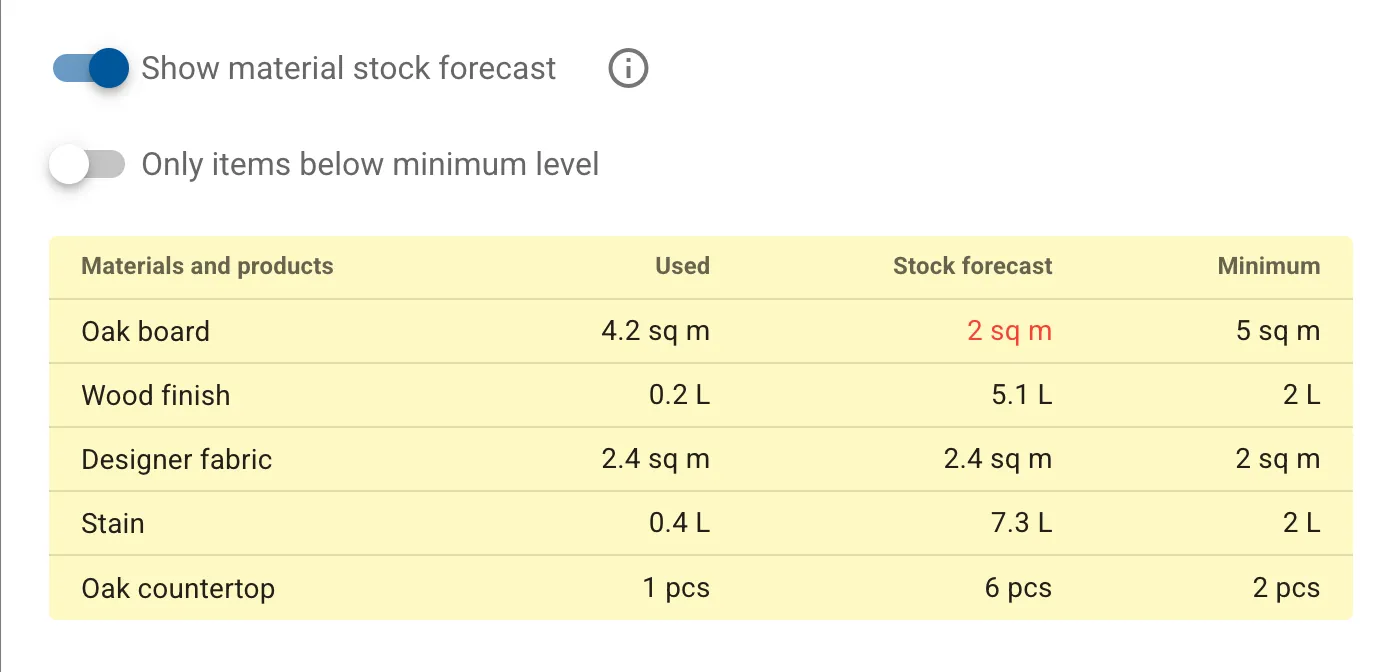

MRP - Material Requirements Planning

The system automatically calculates raw material and component requirements based on production plans. Get precise data on what and when to purchase, considering current inventory levels and lead times.

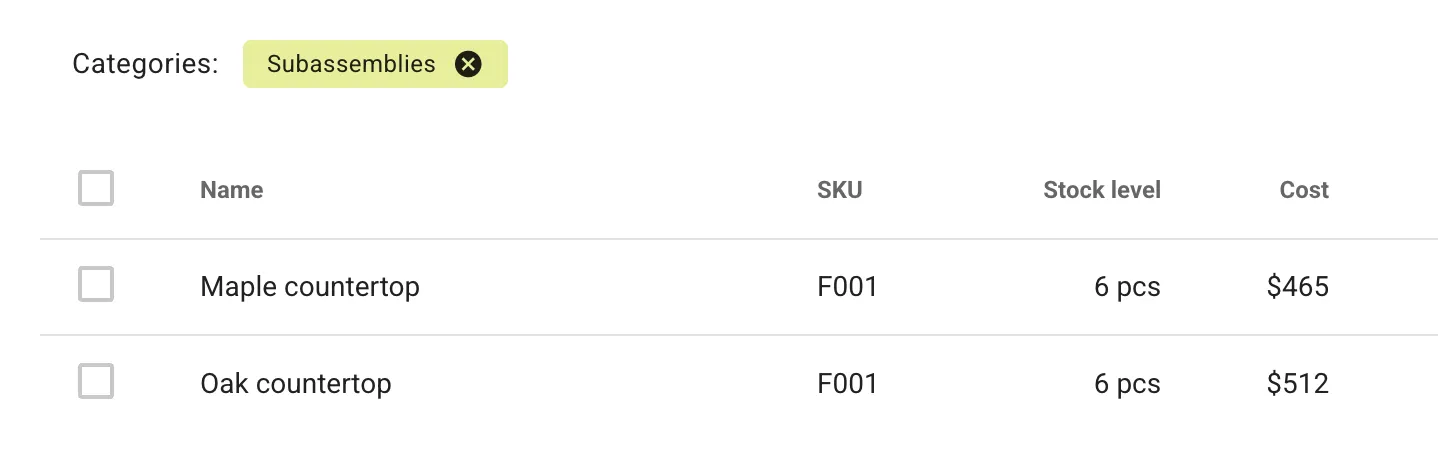

Work in Progress Planning

Plan the movement of semi-finished goods and workpieces between production stages. Control WIP volumes for optimal workstation loading and deadline compliance.

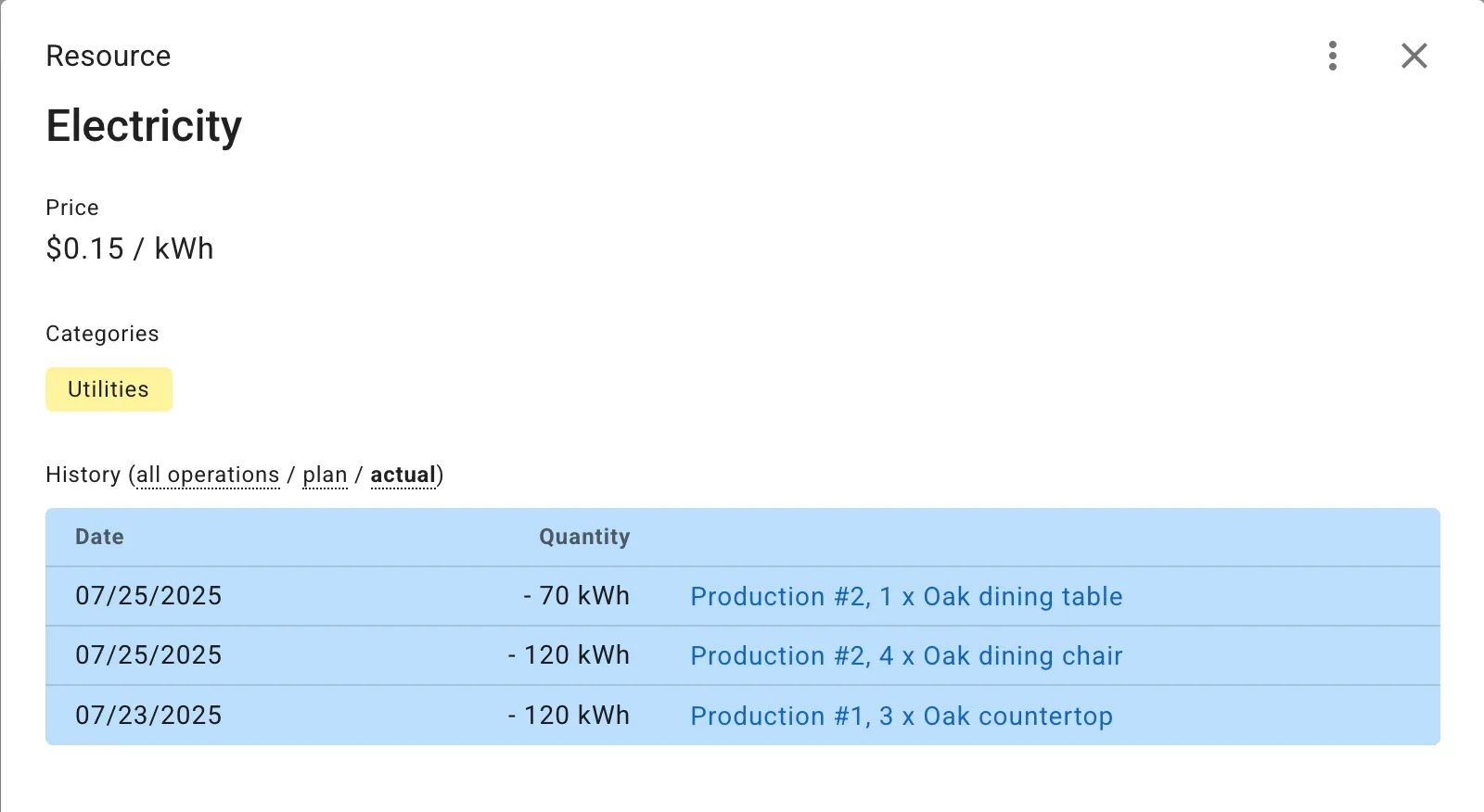

Production Resource Planning

Plan costs for labor resources, equipment depreciation, and overhead expenses. Calculate resource costs needed to execute production plans and forecast product cost of goods sold.

Transform Your Production Planning

Implementing Controlata production planning software provides:

Accurate Timeline Planning

Create realistic production schedules considering technological requirements and material availability. Meet delivery deadlines and avoid rush situations through quality planning.

Resource Optimization

Efficiently plan the use of materials, labor, and other resources. Minimize waste and optimize production costs through better resource planning.

Optimal Procurement Planning

MRP system calculates precise material requirements, eliminating excessive purchases. Plan just-in-time deliveries and reduce inventory storage costs.

Production Plan Compliance

Track production plan execution in real-time. Identify deviations promptly and adjust plans to achieve target performance indicators.

Process Synchronization

Align production plans with sales, procurement, and logistics plans. Ensure coordinated operation of all enterprise departments.

Reduced Planning Time

Automate routine planning operations and free up planners' time for analysis and strategic decision-making. Accelerate the plan creation process.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.