Production Process Software

Transform your manufacturing operations with Controlata's comprehensive production process software. Designed specifically for manufacturers to plan production runs, track progress, monitor resource consumption, and maintain complete visibility over your manufacturing operations from start to finish.

Controlata Production Process Management

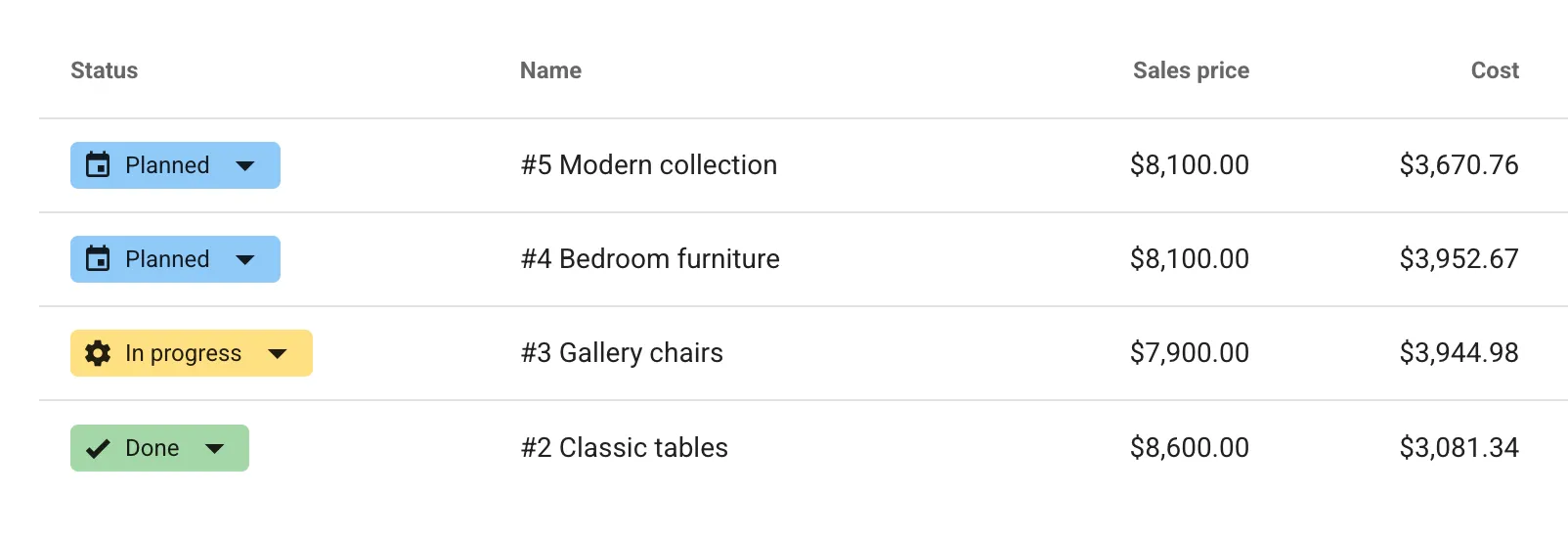

Production Planning & Scheduling

Create detailed production plans with clear timelines and resource requirements. Plan manufacturing runs based on customer orders, material availability, and production capacity. Set priorities and track progress against planned schedules.

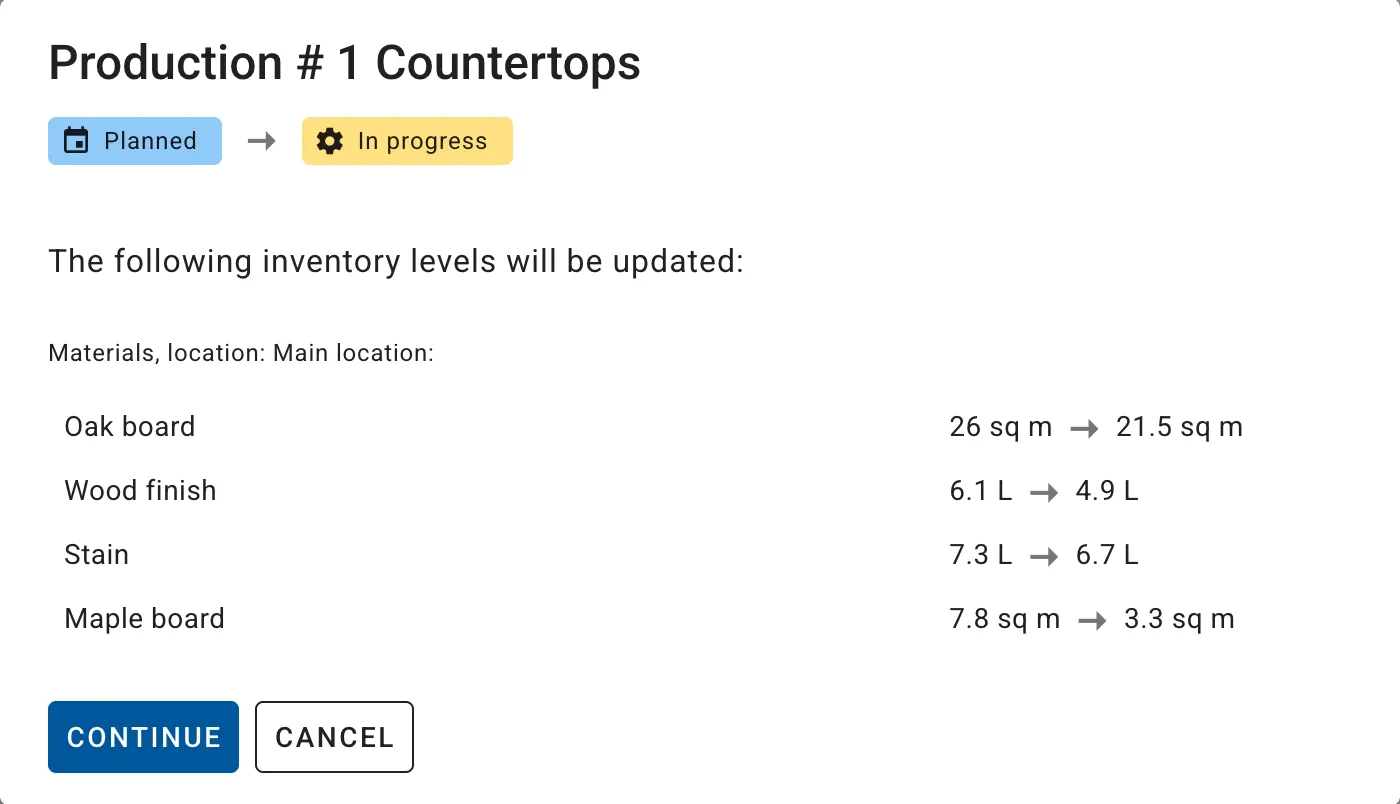

Real-time Production Tracking

Monitor every stage of your manufacturing process in real-time. Track work-in-progress status, update production milestones, and maintain complete visibility over current production status across all manufacturing operations.

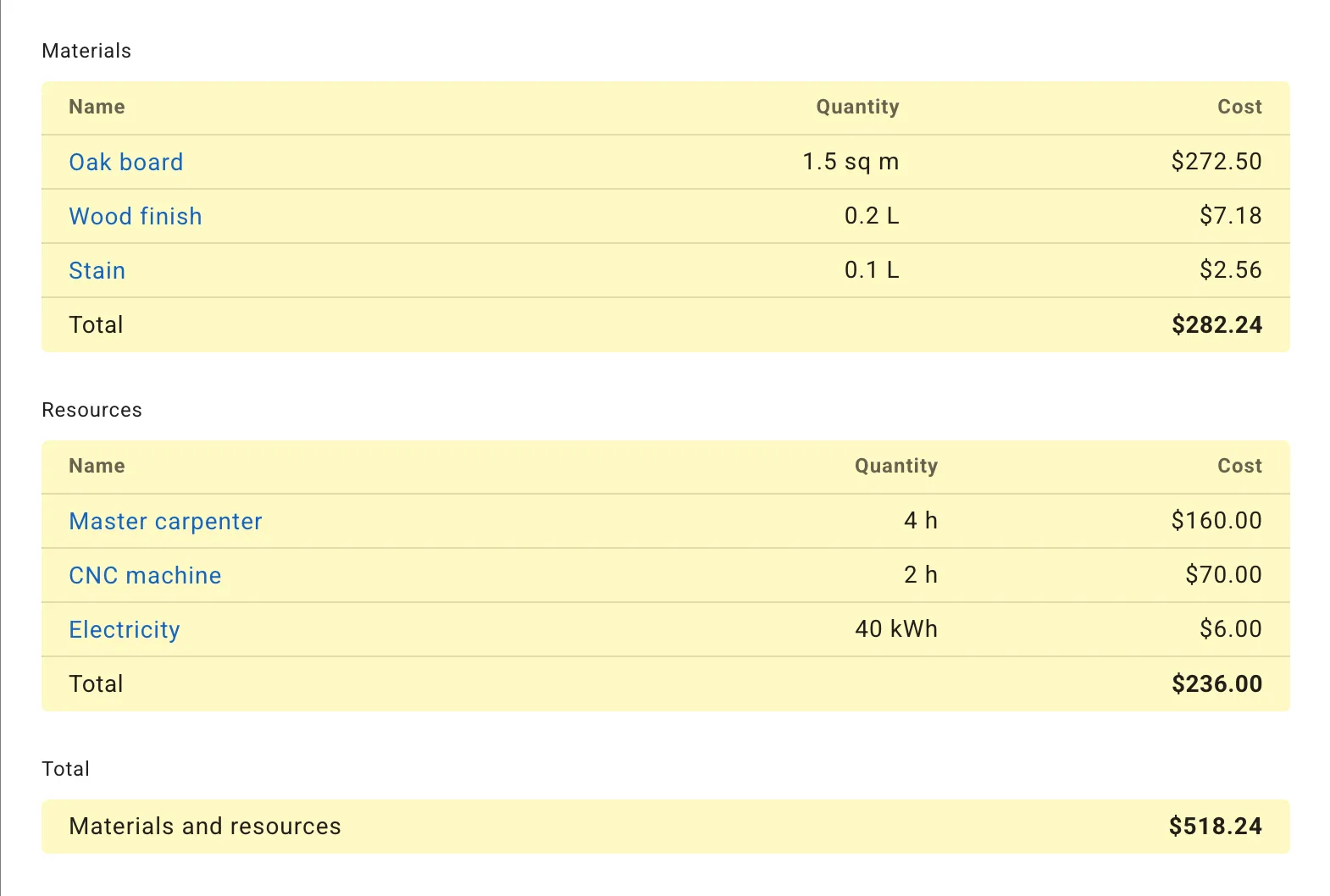

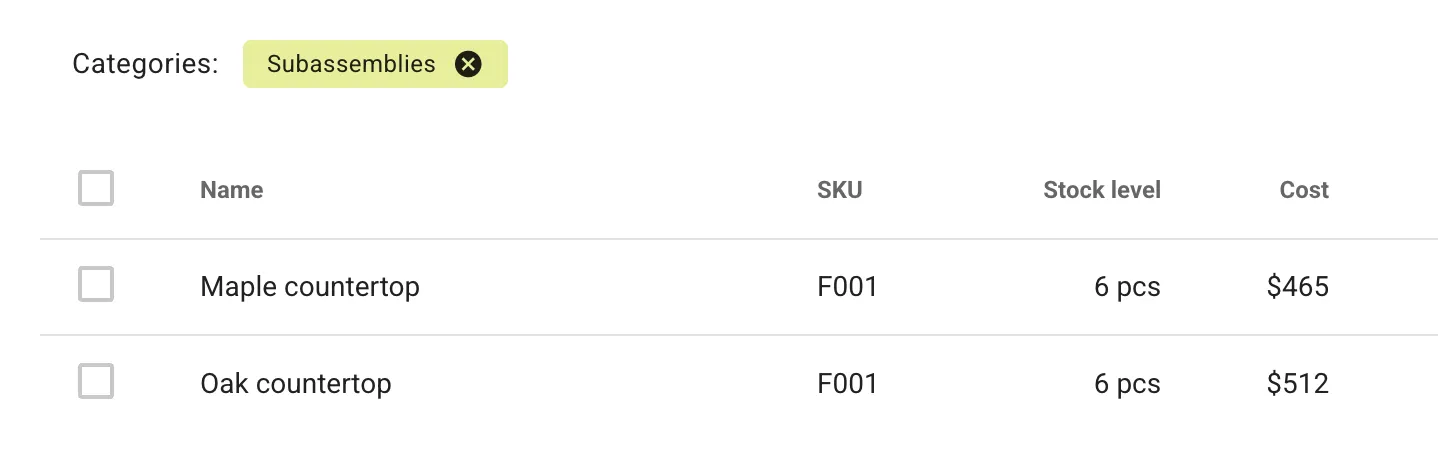

Bill of Materials Management

Define detailed production recipes including materials, labor requirements, equipment usage, and overhead costs. Automatically calculate material requirements for production runs and track actual consumption against planned usage.

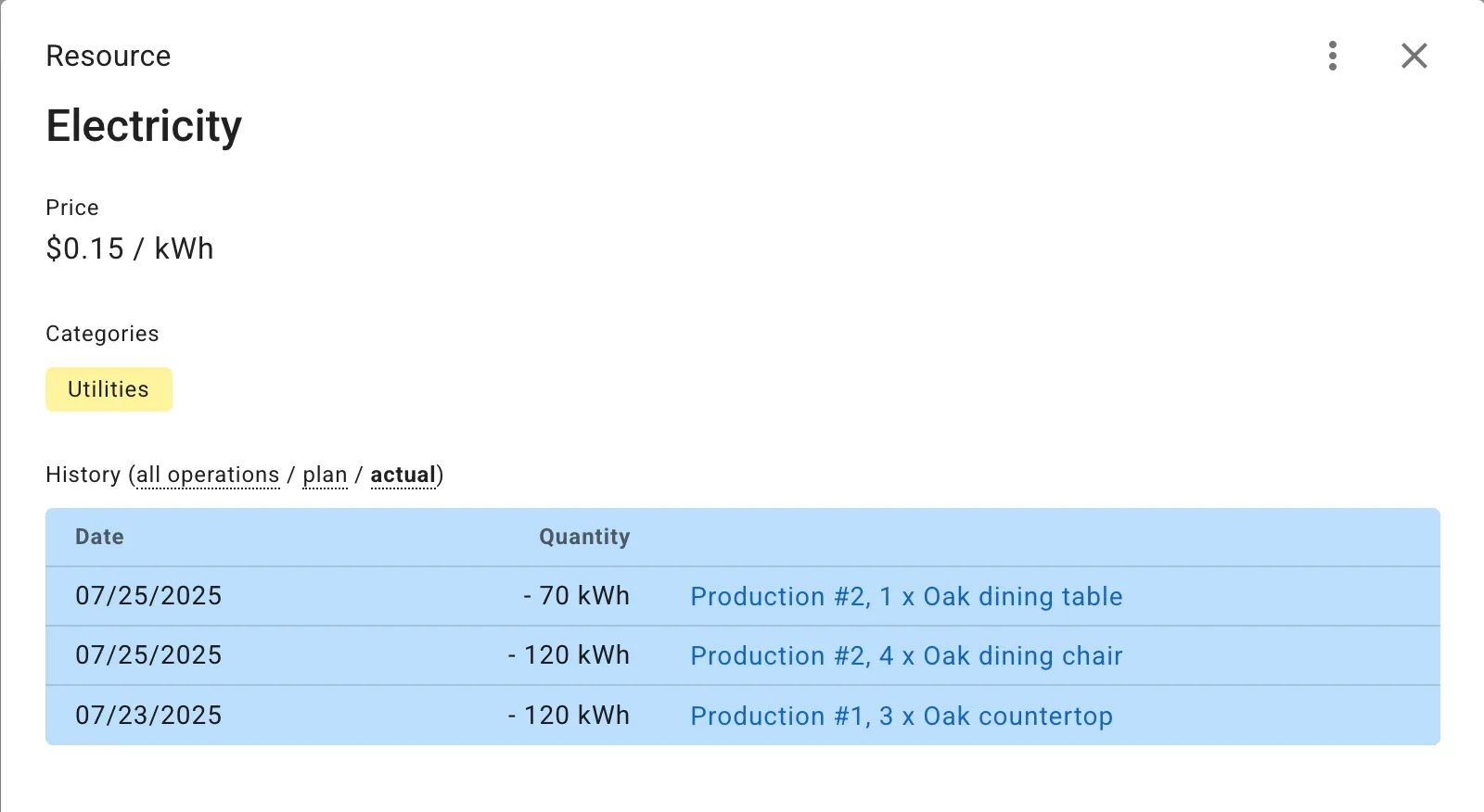

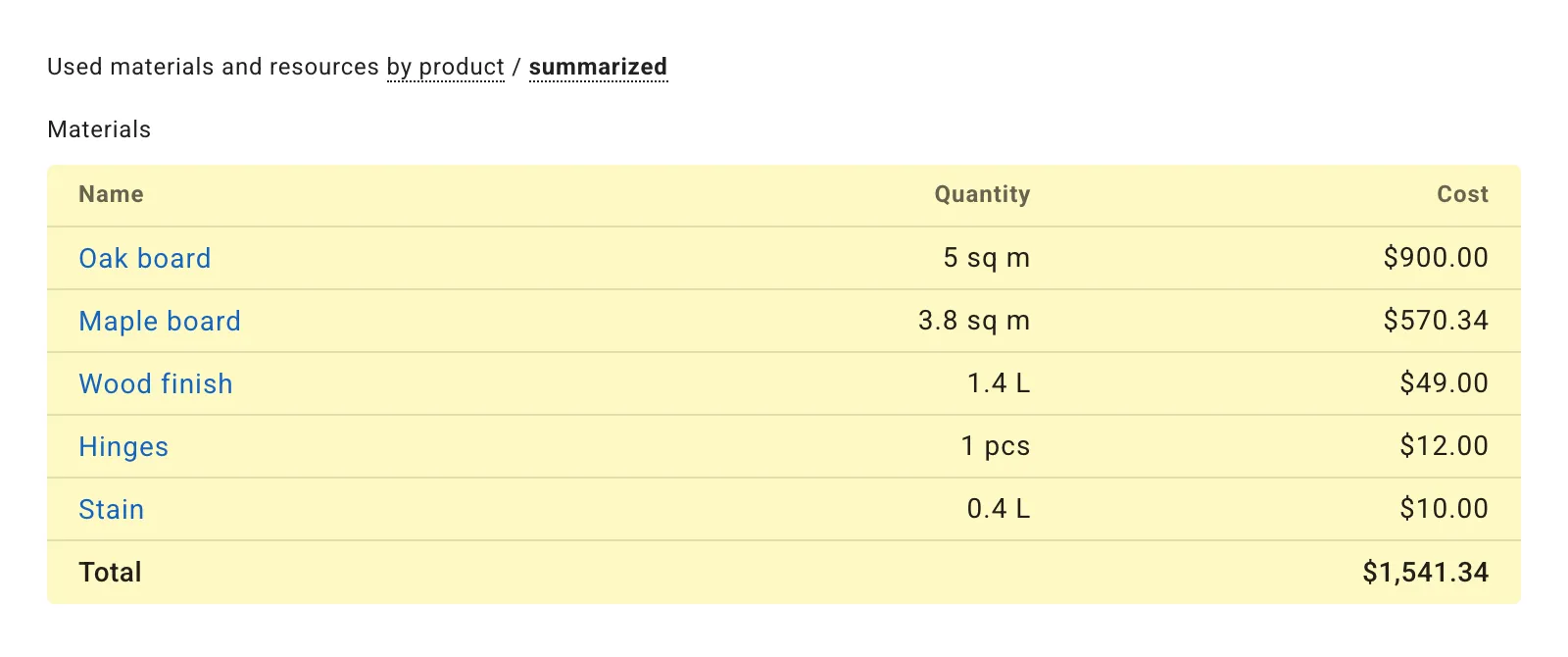

Resource Usage Monitoring

Track actual resource consumption during production including materials, labor time, and equipment usage. Monitor performance against planned resource requirements and identify areas for optimization and cost reduction.

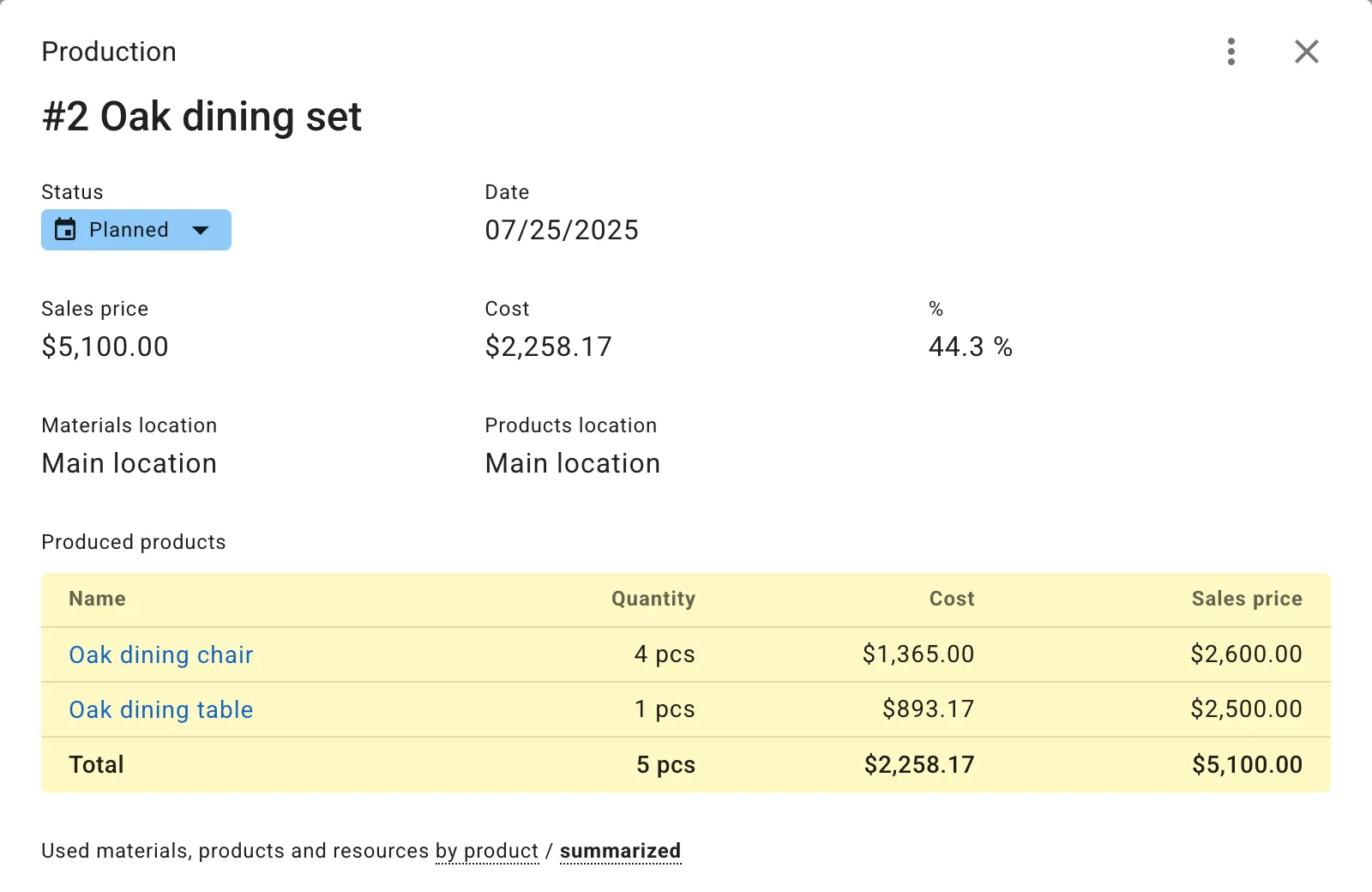

Production Cost Tracking

Calculate accurate production costs automatically based on actual material usage, labor time, and overhead allocation. Track cost performance by production run and analyze cost trends over time for better decision making.

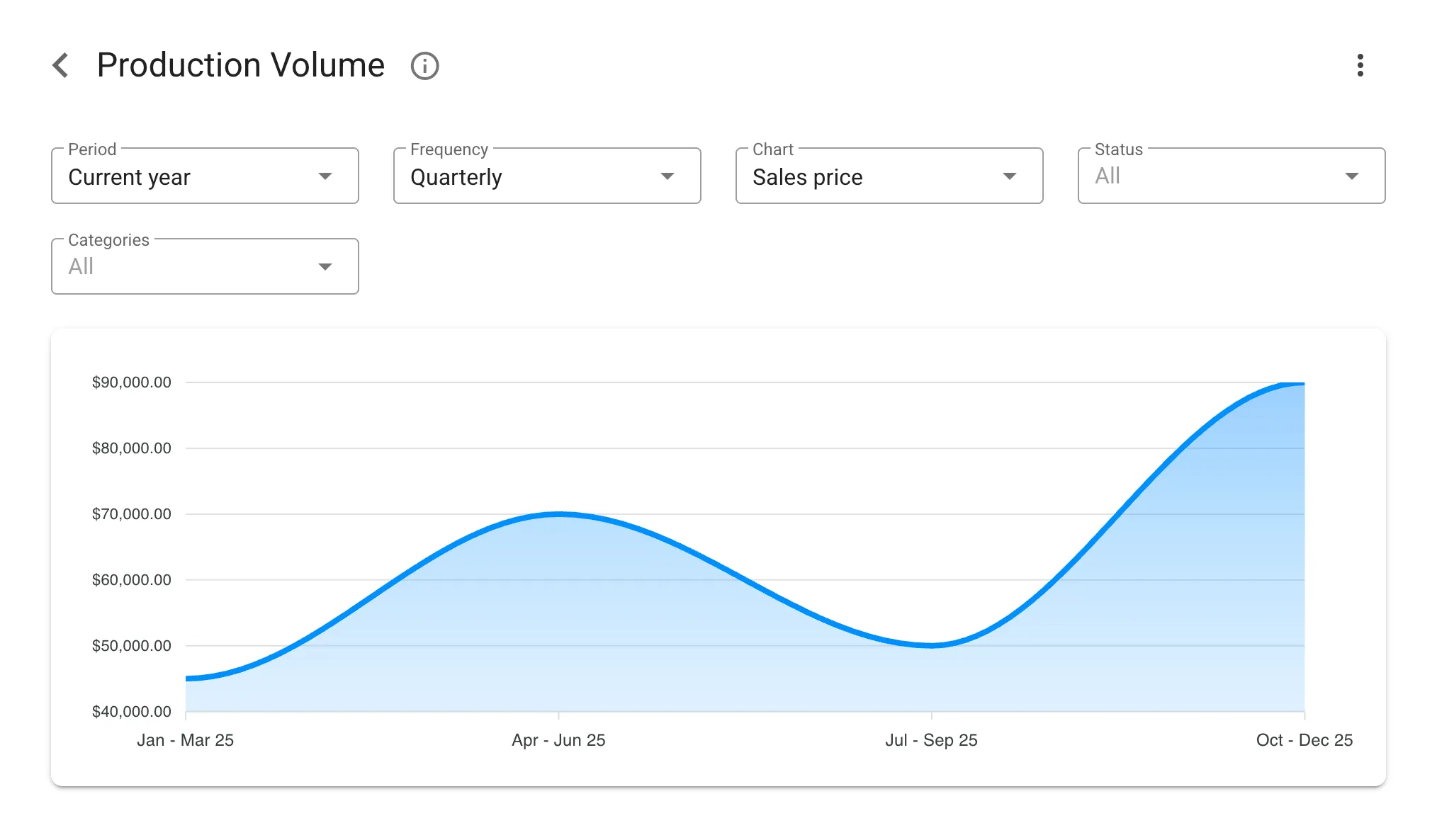

Production Analytics & Reports

Gain insights with comprehensive production reporting. Monitor key performance metrics, track efficiency trends, and analyze production data through detailed reports and visual dashboards for continuous improvement.

Material Consumption Control

Automatically track material consumption based on production recipes. Monitor material usage against planned quantities, identify variances, and ensure accurate inventory deduction as production progresses.

Multi-stage Production Control

Manage complex manufacturing processes with multiple production stages. Track progress through each stage, coordinate transfers between operations, and maintain full visibility throughout the entire production cycle.

Optimize Manufacturing Operations

Enhance your production efficiency with Controlata's manufacturing process software. Our solution helps you:

Improve Production Efficiency

Streamline production planning and tracking with clear visibility into progress and resource usage. Identify bottlenecks quickly and make informed decisions to optimize manufacturing throughput.

Better Schedule Management

Create realistic production timelines based on actual capacity and material availability. Track progress against schedules and adjust plans proactively to meet delivery commitments.

Enhanced Production Visibility

Monitor production progress across all operations with real-time status updates. Track key metrics, analyze performance trends, and make data-driven decisions for continuous improvement.

Accurate Cost Control

Track actual production costs with precise material consumption and labor time recording. Compare actual costs against planned budgets and identify opportunities for cost optimization.

Streamlined Workflows

Coordinate production activities with integrated material management and automatic status updates. Reduce manual coordination tasks and minimize delays between production stages.

Data-Driven Insights

Analyze production performance through comprehensive reporting and analytics. Track efficiency metrics, identify improvement opportunities, and optimize manufacturing processes based on real data.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.