Small Business Inventory Management Software

Purpose-built manufacturing inventory system for small business owners. Manage raw materials, track production costs, and control finished goods inventory with software designed specifically for small manufacturing operations.

Inventory System for Small Manufacturing Business

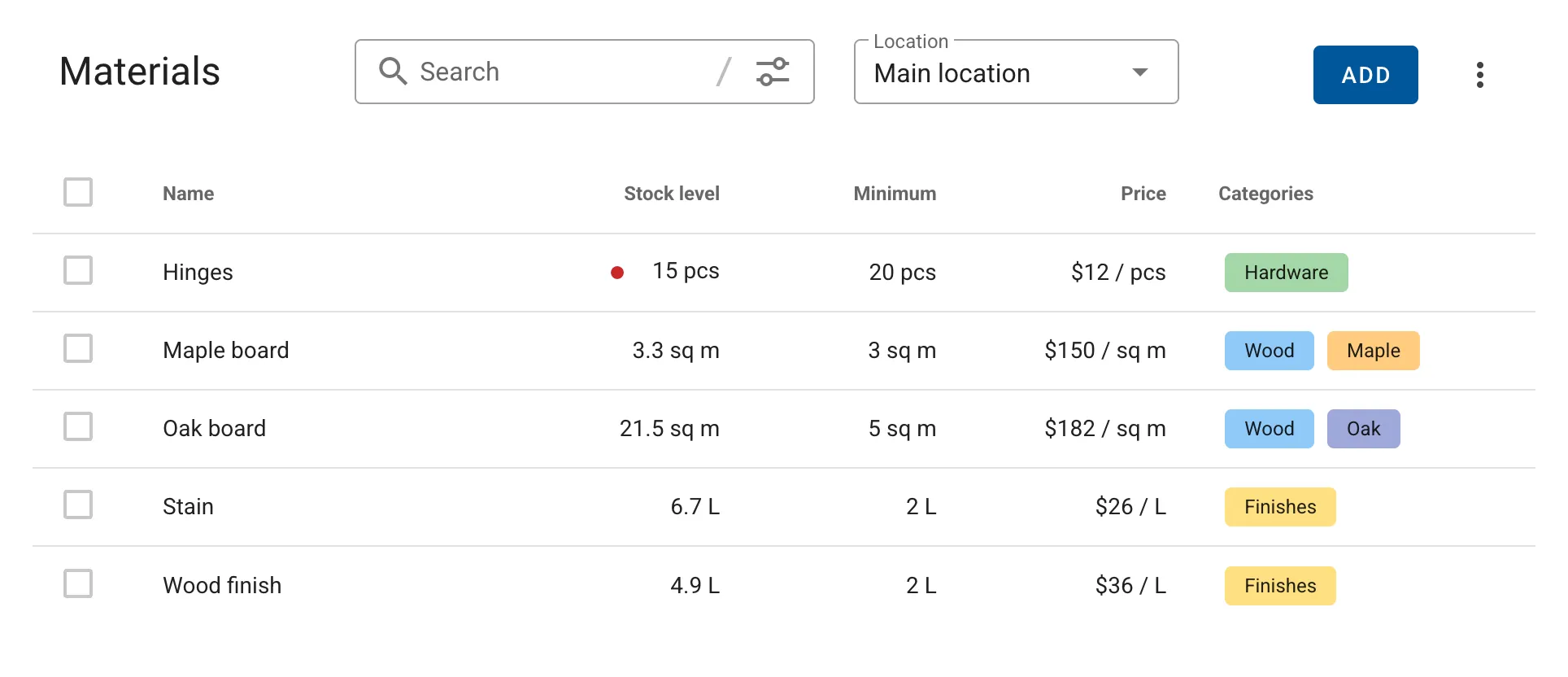

Raw Materials Tracking

Keep precise control over your raw materials inventory with our manufacturing-focused system. Track material consumption, monitor supplier deliveries, and ensure you always have the right materials for production runs.

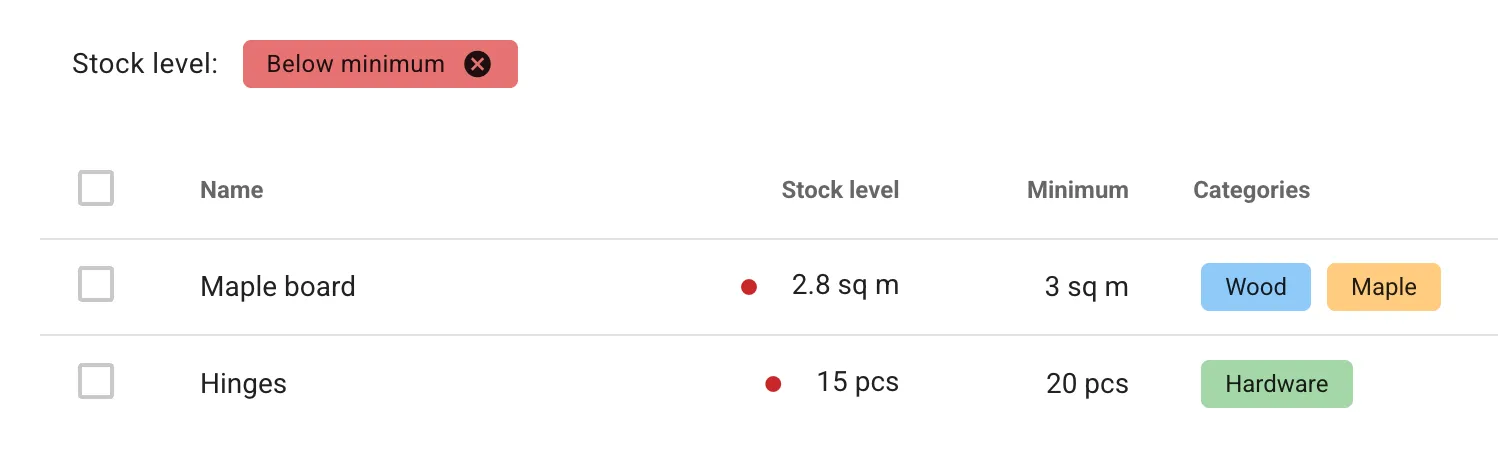

Smart Reorder Alerts

Prevent production delays with intelligent low-stock notifications. Set minimum levels for critical materials and get alerts before you run out, keeping your small manufacturing operation running smoothly.

Easy-to-Learn Interface

Start using our inventory system for small business immediately with an intuitive design that requires no training. Built specifically for busy small business owners who need powerful features without complexity.

Production Cost Tracking

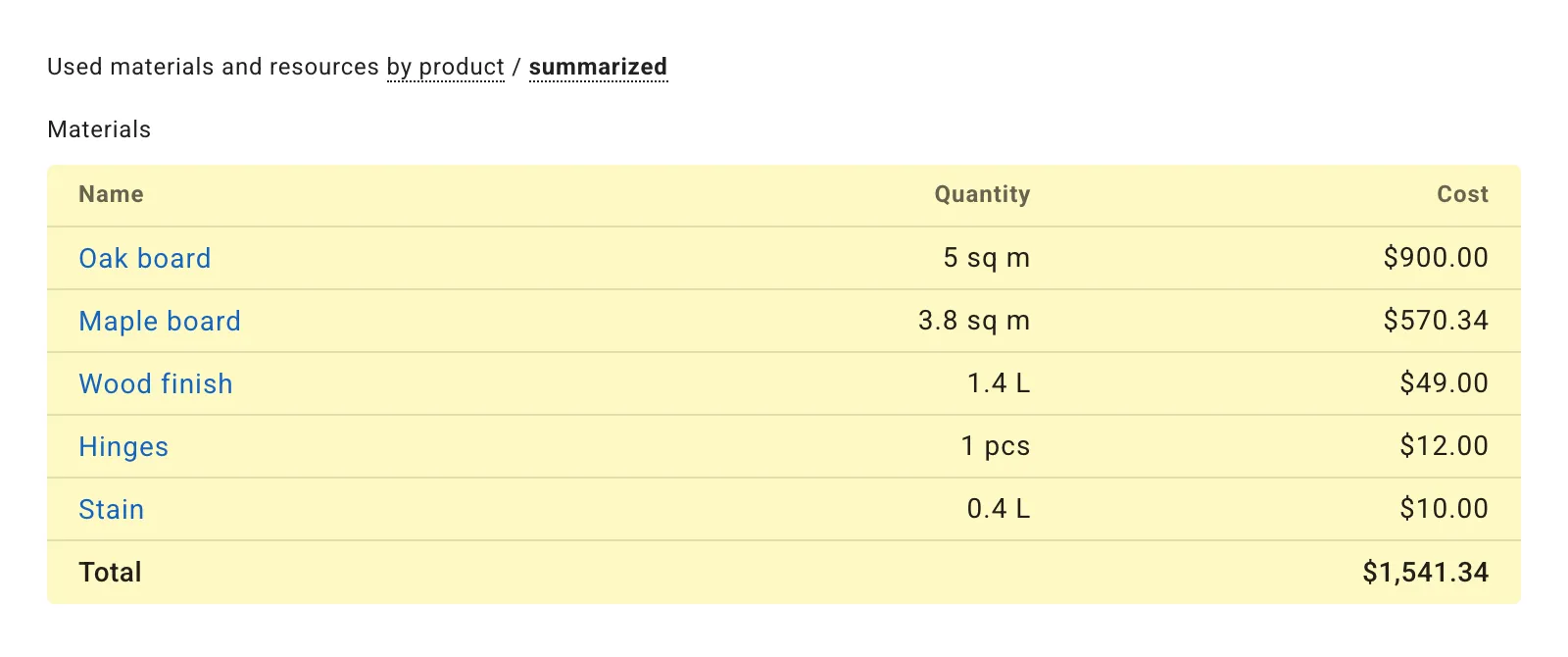

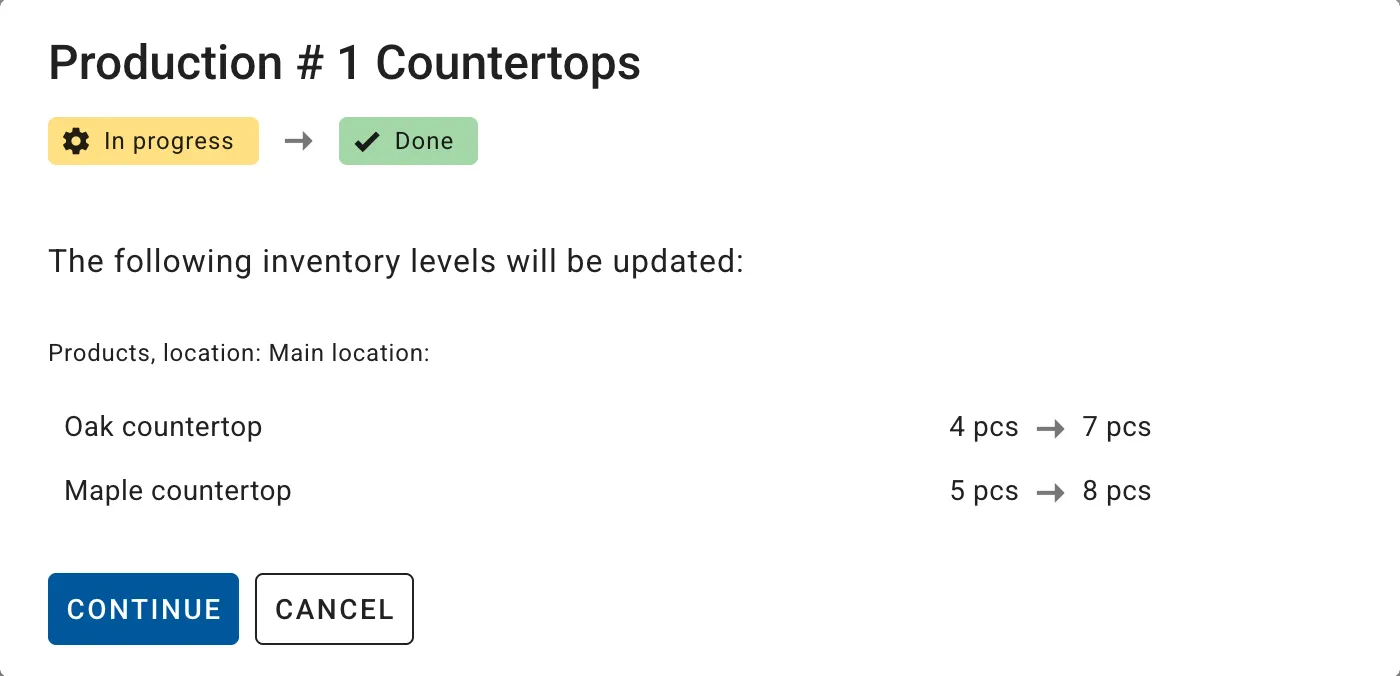

Calculate accurate production costs automatically as you manufacture products. Our small business inventory software tracks material usage, labor costs, and overhead expenses to give you real profitability insights.

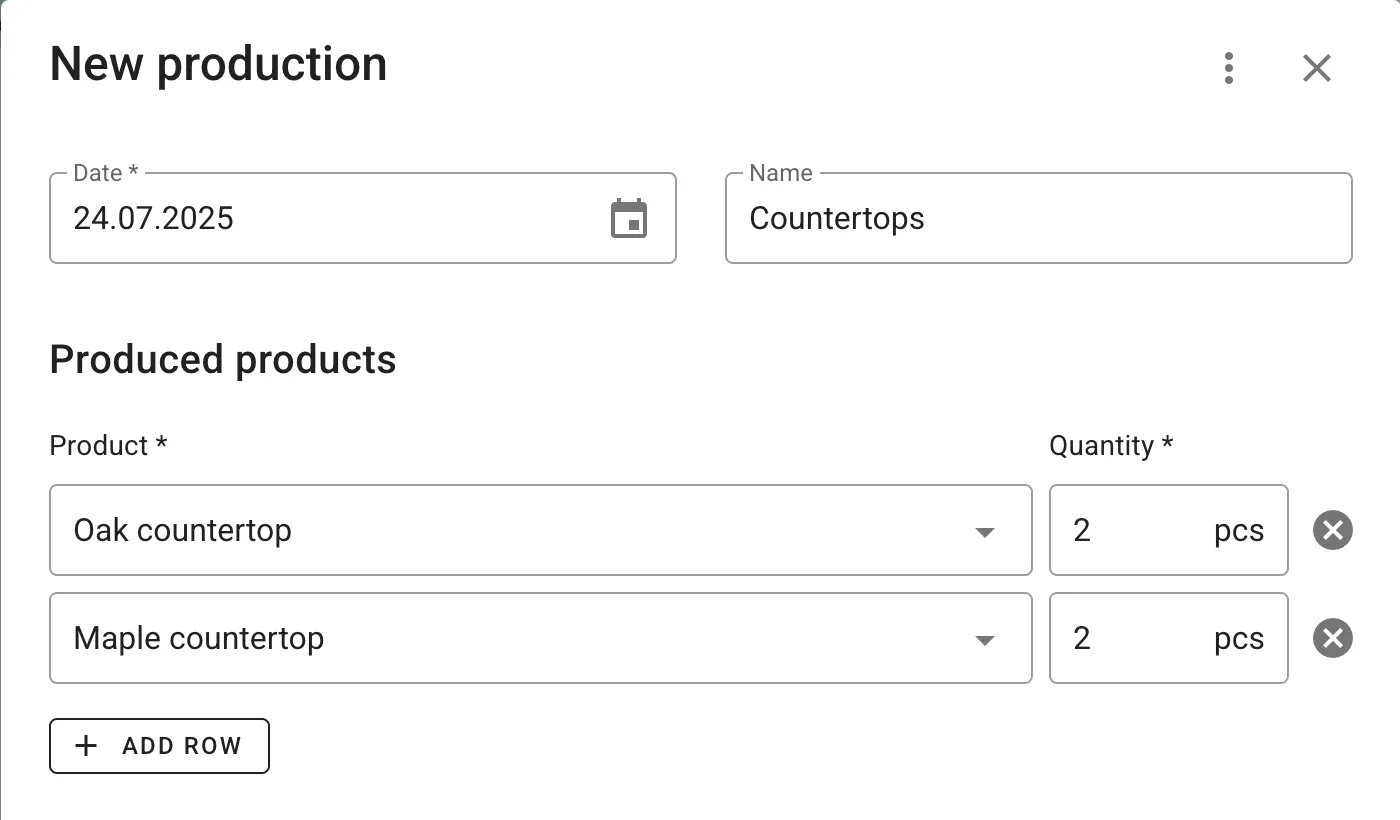

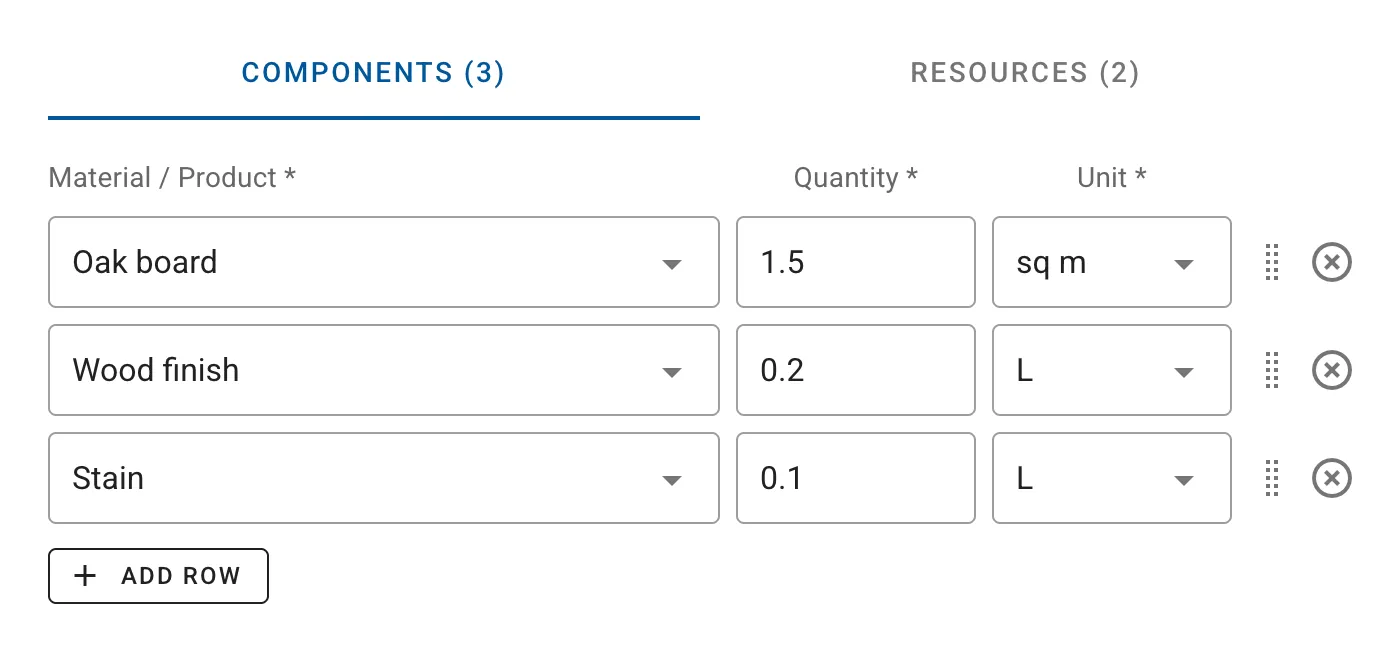

Bill of Materials Management

Create detailed recipes for your products with our bill of materials feature. Define exactly what materials and quantities are needed for each product, enabling accurate cost calculation and automatic material deduction during production.

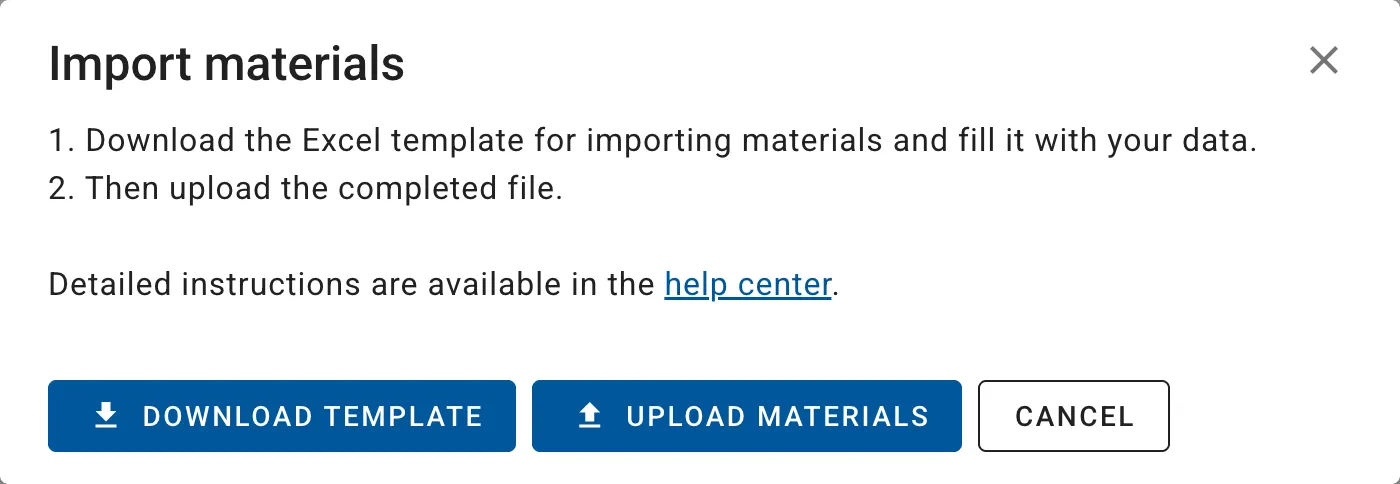

Quick Business Setup

Get your small manufacturing business up and running in minutes. Import your existing product and material data from Excel, or start fresh with our guided setup process designed for small business owners.

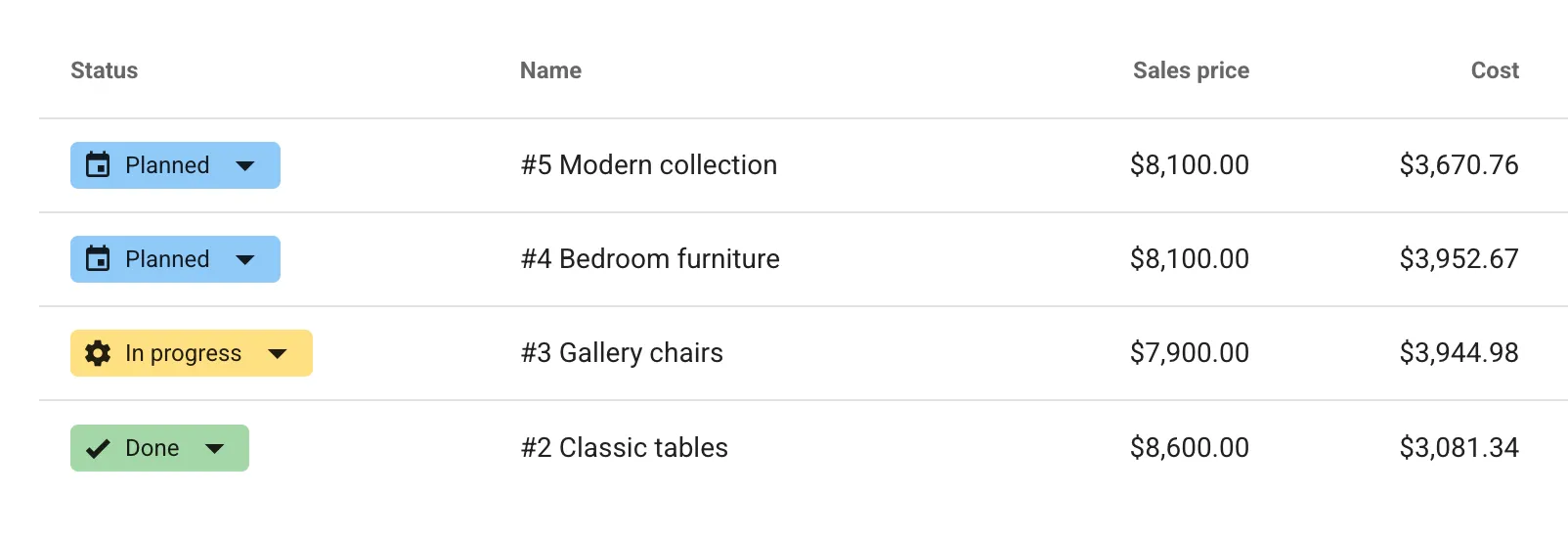

Production Planning

Plan your manufacturing runs efficiently with integrated production scheduling. See what materials you need, check availability, and ensure you can fulfill customer orders on time with our manufacturing inventory system.

Finished Goods Control

Track your finished products from completion to sale. Monitor finished goods inventory levels, manage customer orders, and ensure accurate costing for profitable pricing decisions in your small manufacturing business.

Why Small Manufacturers Choose Our System

Our manufacturing inventory system for small business delivers real results for growing companies:

Control Material Costs

Reduce waste and optimize material purchasing with accurate consumption tracking. Our inventory software for small business helps manufacturers identify cost savings and improve profitability.

Save Time Daily

Eliminate manual inventory counting and spreadsheet management. Automate routine tasks so you can focus on growing your small manufacturing business instead of managing paperwork.

Know Your True Costs

Calculate exact product costs including materials, labor, and overhead. Make informed pricing decisions and identify your most profitable products with detailed cost analysis.

Grow with Confidence

Scale your manufacturing operations with reliable inventory data. Our small business system grows with you, handling increased product lines and higher volumes without complexity.

Improve Order Fulfillment

Meet customer delivery dates consistently with better production planning. Know exactly what materials you have and what you need to complete every order on time.

User-Friendly Design

Start benefiting immediately with software designed for real small business owners. No technical expertise required - if you can use email, you can master our inventory system for small business.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.