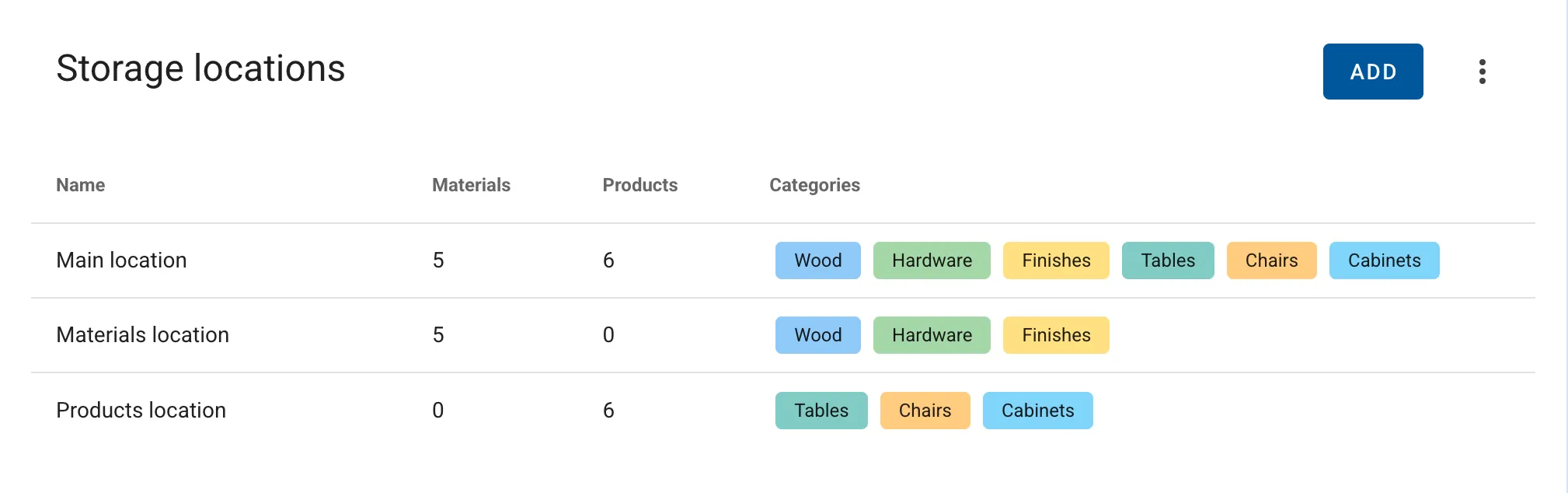

Storage Locations for Manufacturing

Controlata is a multi-location inventory management system for manufacturers. Track materials and finished goods separately for each storage location, monitor transfers between locations, and automate inventory management.

Storage Location Management Features

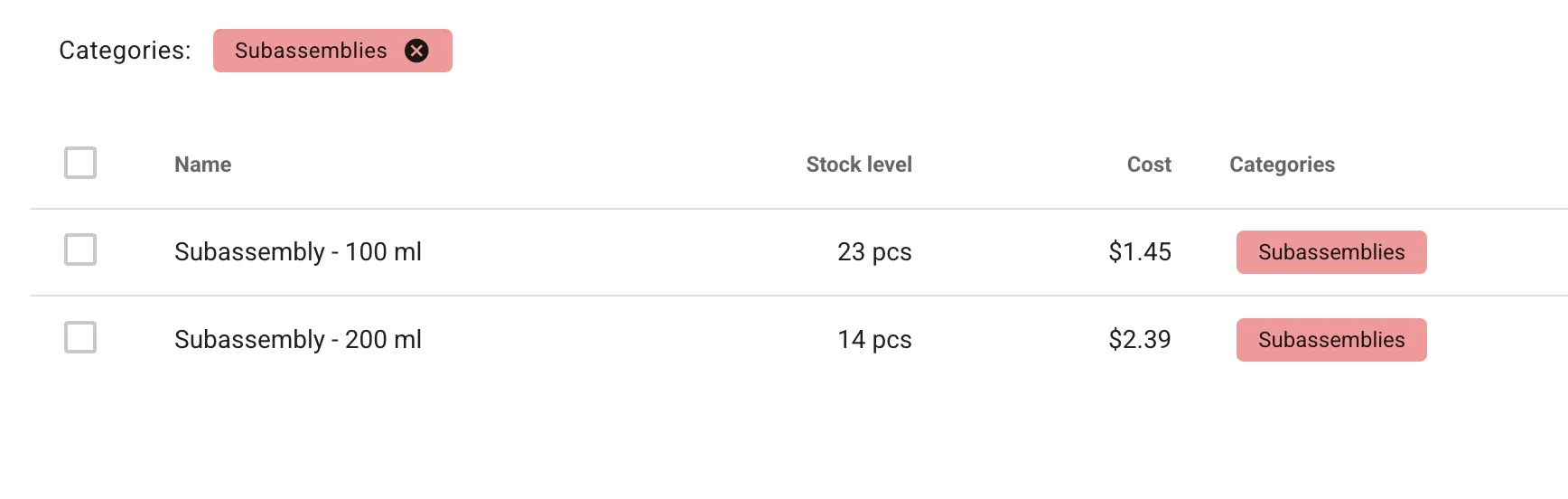

Real-time Inventory Tracking Across Locations

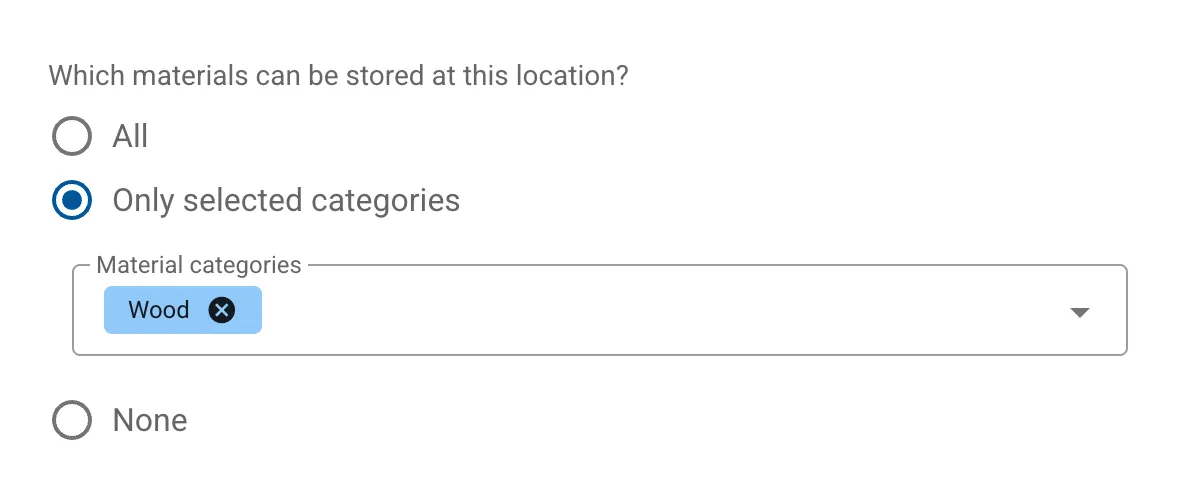

Track and manage unlimited storage locations with Controlata's comprehensive inventory system. Monitor stock levels across raw materials, packaging, components and more - all in real-time. Streamline receiving, consumption and transfer operations with automated workflows.

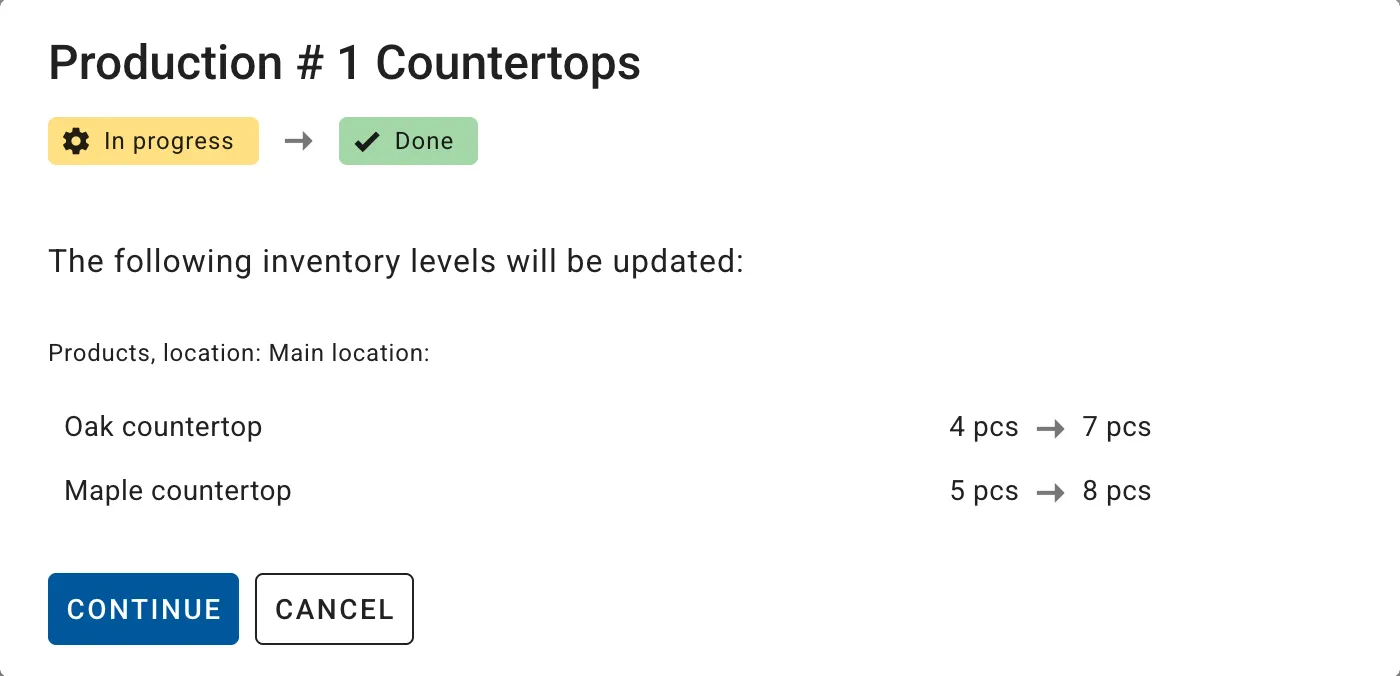

End-to-End Finished Goods Management

Take control of your finished goods inventory with dedicated storage zones. Get instant visibility into stock levels and movements as products come off production. Maintain accurate finished goods tracking with automated receiving workflows.

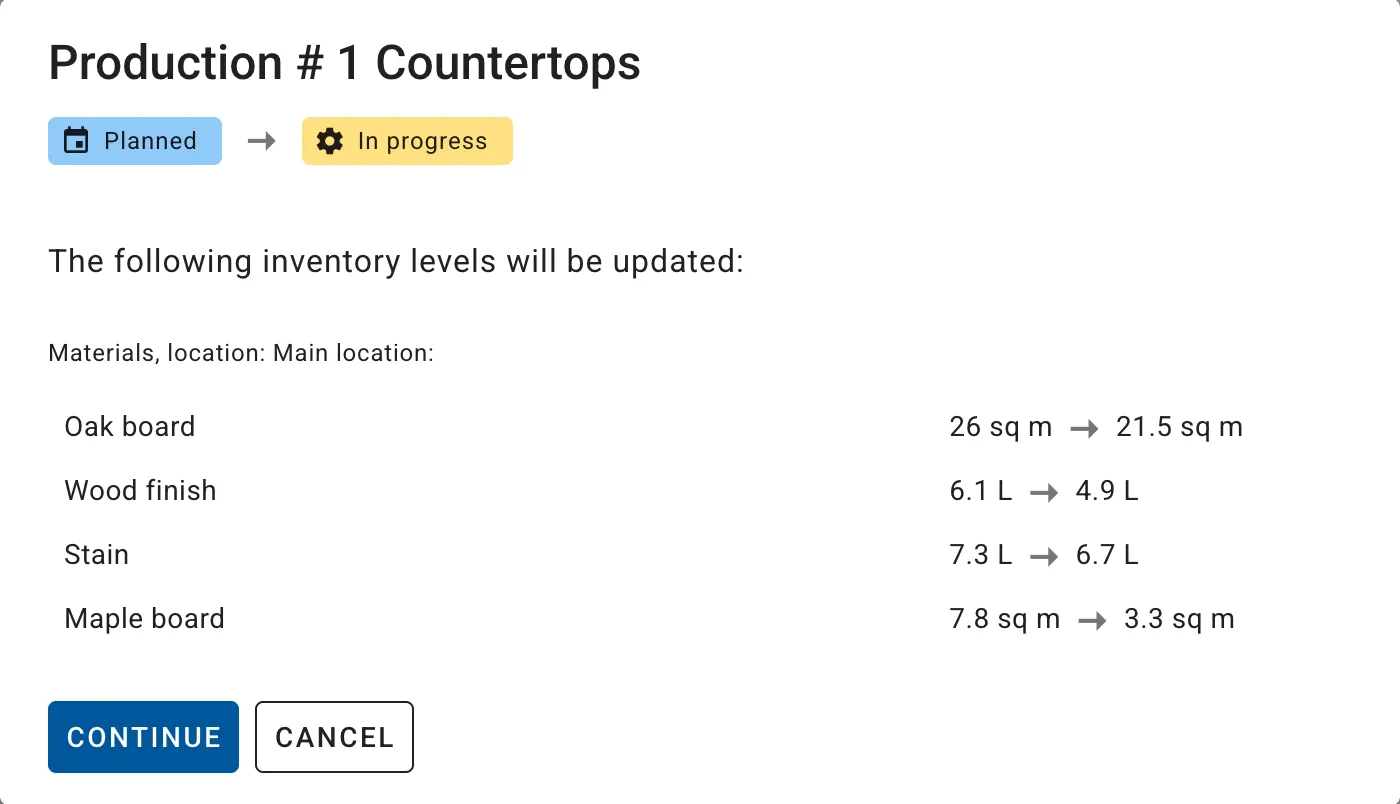

Smart Material Requirements Planning

Eliminate manual material handling with intelligent automation. Materials are automatically allocated and consumed based on your bill of materials - ensuring accurate stock levels and seamless production flow with zero manual intervention.

Streamlined Production Receipt Process

Simplify finished goods receiving with automated workflows. As production completes, items are automatically received into inventory with accurate costs and quantities calculated from production data - reducing errors and manual effort.

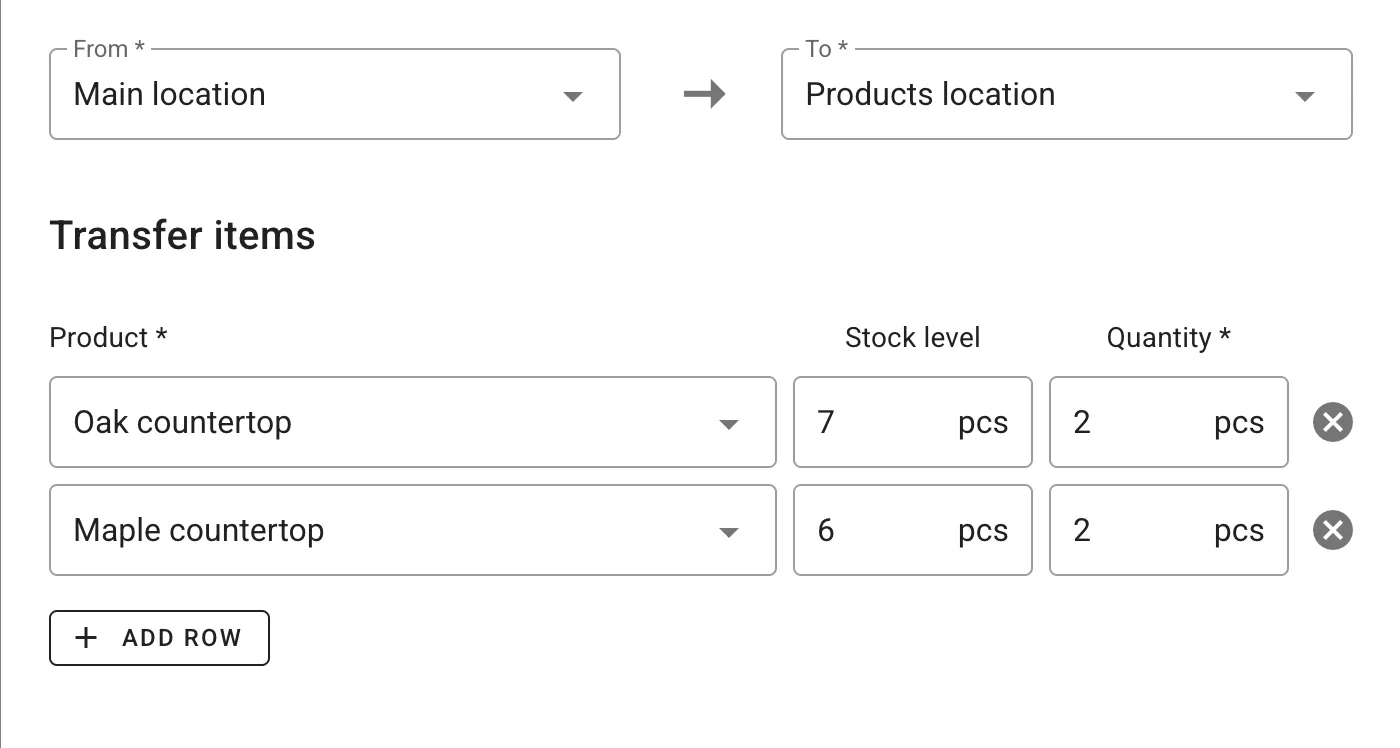

Efficient Inter-Location Movement

Move inventory seamlessly between locations with full traceability. Whether transferring from warehouse to production floor or shipping area, our transfer documents provide complete chain of custody and inventory accuracy.

Complete Work in Progress Visibility

Gain total control over work in progress across your entire production process. Track WIP inventory at each stage with dedicated storage locations. Document all movements between production phases for full traceability and accurate costing.

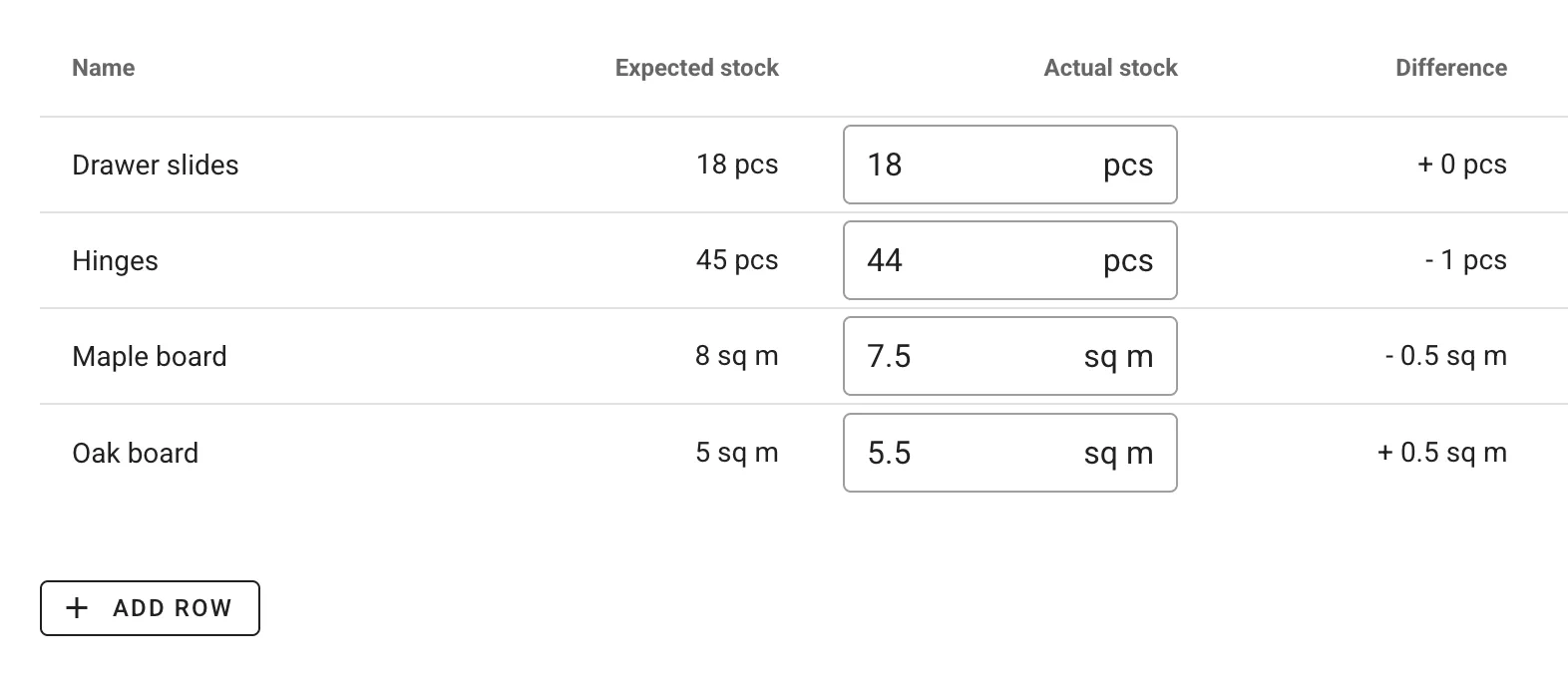

Accurate Inventory Auditing

Maintain inventory accuracy with comprehensive audit capabilities. Record physical counts, reconcile with system data, and process variances efficiently. Regular auditing helps prevent stockouts and maintain optimal inventory levels.

Why Choose Controlata for Inventory Control

By implementing Controlata for inventory and production management, you will achieve:

Organized Inventory Management

Real-time tracking of all receipts, transfers, and consumption ensures accurate stock levels of materials and products, preventing shortages and unaccounted surplus.

Work in Progress Control

Track WIP movements between production stages, monitor volumes and costs, identify bottlenecks and optimize process efficiency.

Transparent Operations

All material consumption and finished goods receiving operations are automated and available for analysis at any time.

Accurate Costing

FIFO method for material transfers ensures precise manufacturing cost calculations. Prevents cost inflation and profit distortion.

Efficient Auditing

Inventory audit features save time, eliminate paperwork, and reduce human error when counting and reconciling physical versus system stock levels.

Reduced Production Cycle

Automated material consumption and production receipt processes minimize documentation time and accelerate manufacturing workflow.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.