Warehouse Management System

Streamline your warehouse operations with Controlata's manufacturing-focused inventory system. Track materials across multiple locations, automate stock movements, and maintain real-time visibility of your warehouse inventory. Perfect WMS system for growing manufacturing businesses.

Essential Warehouse Management Features

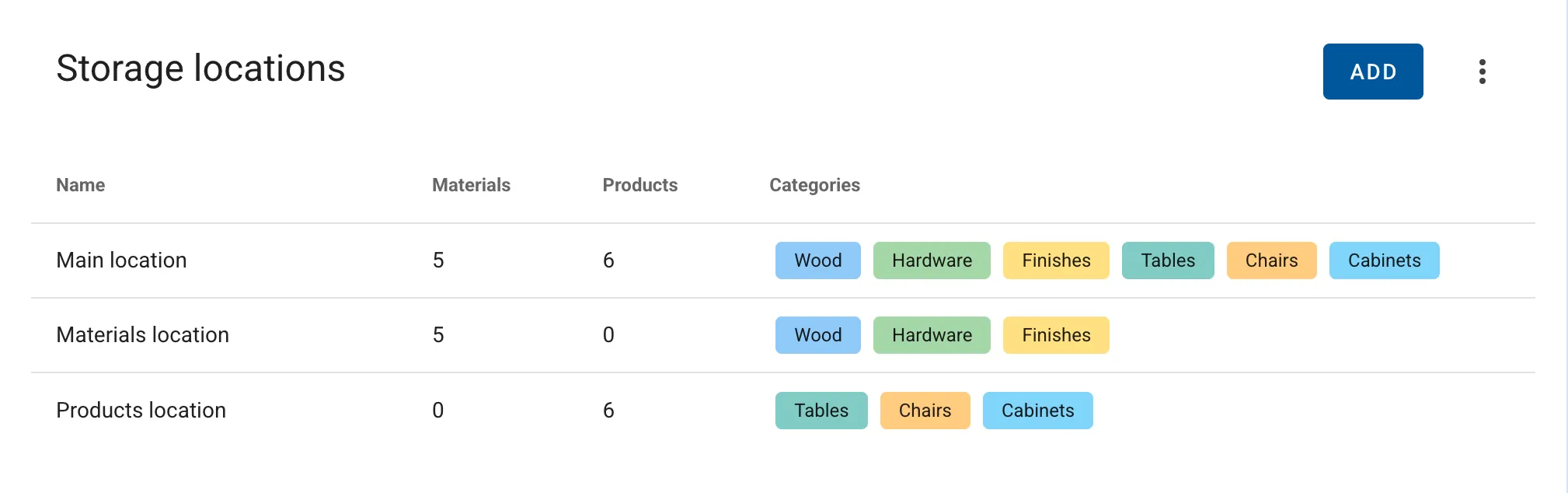

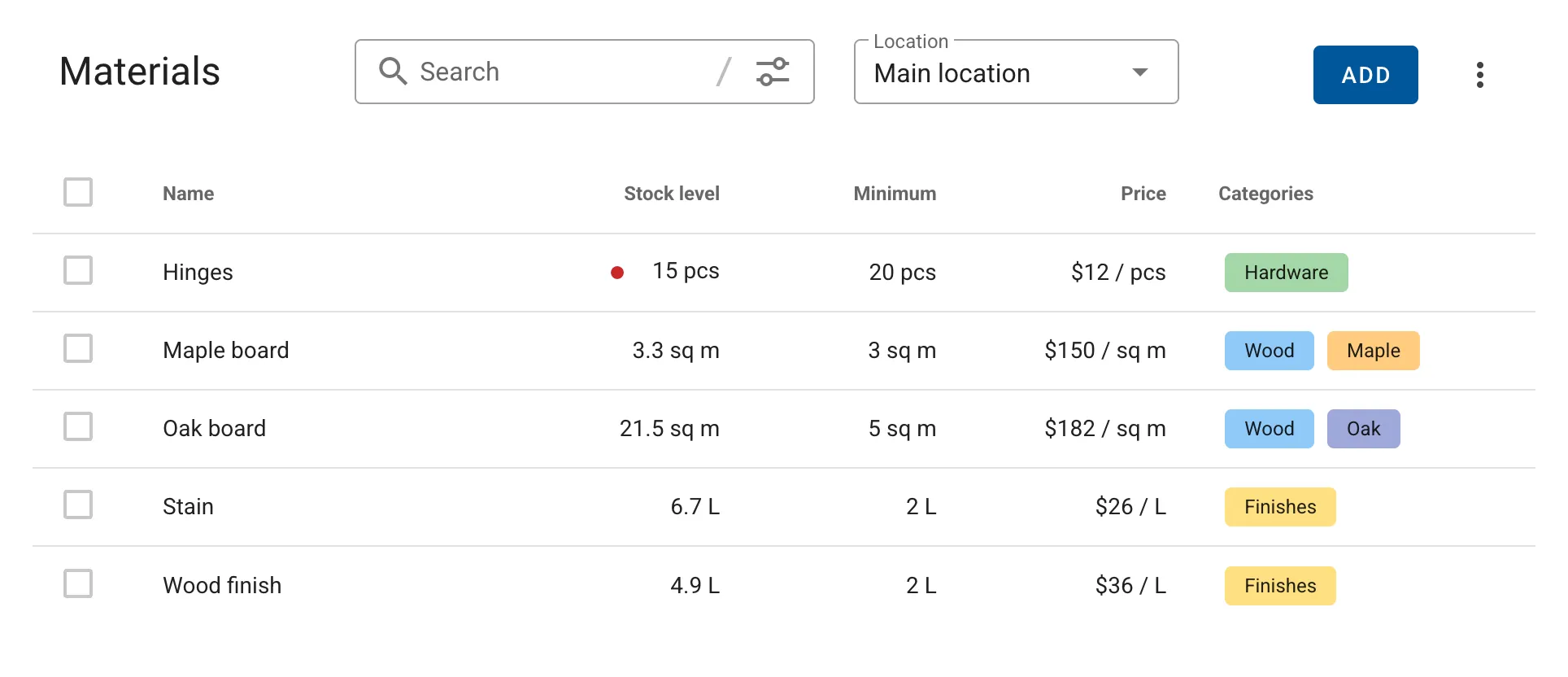

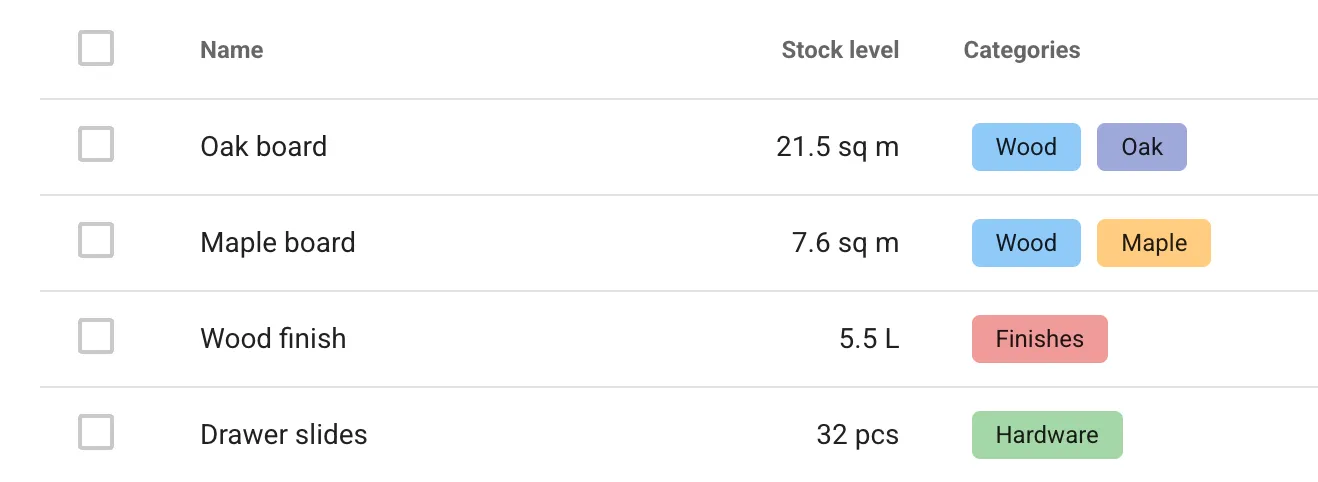

Multi-Location Inventory Control

Manage inventory across multiple warehouse locations with real-time visibility. Track raw materials, work-in-progress, and finished goods separately. Configure unlimited storage locations and monitor stock levels across your entire warehouse network.

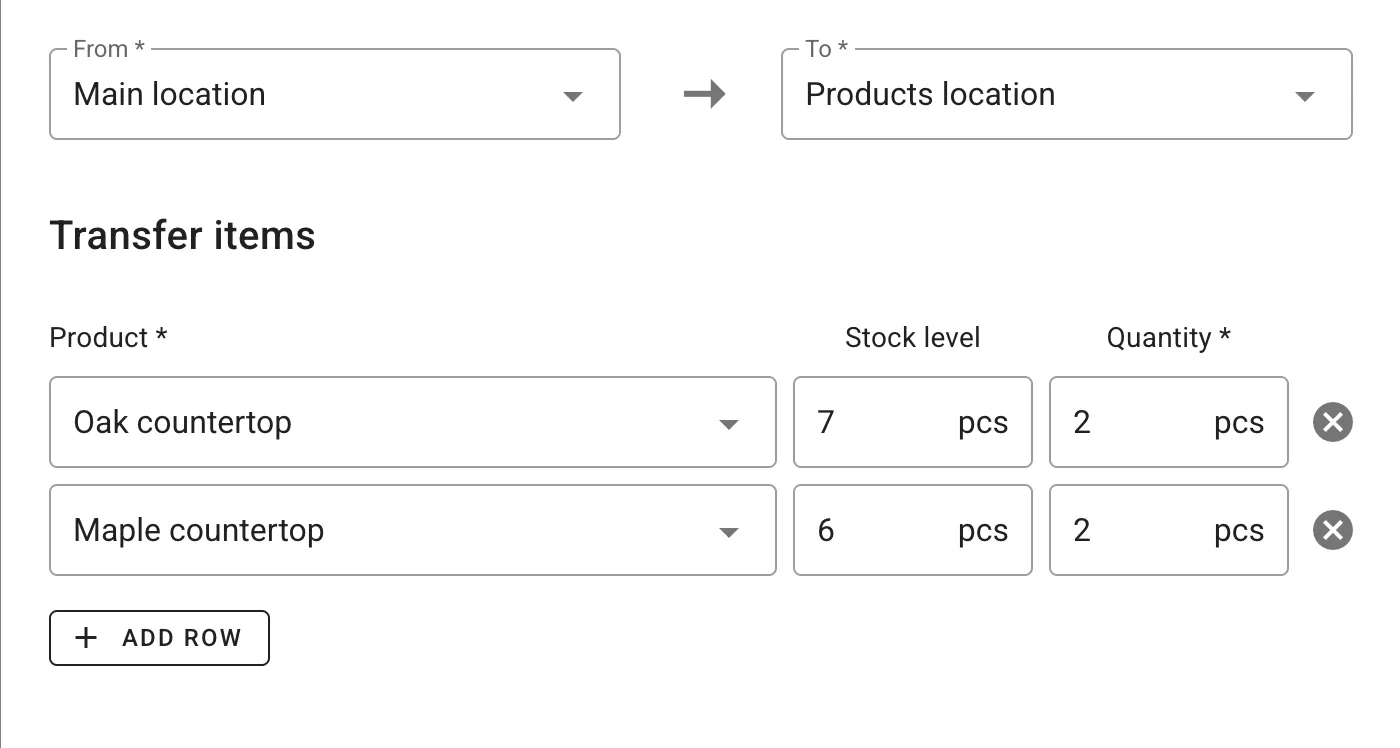

Automated Stock Movement Tracking

Monitor every inventory movement with precision. Track transfers between warehouse locations, record receipts and shipments, and maintain accurate stock levels automatically as materials move through your manufacturing process.

Real-time Warehouse Visibility

Access your warehouse data instantly from any device. Monitor stock levels, track material consumption, and view inventory status across all locations with up-to-the-minute accuracy for informed decision-making.

Smart Stock Categorization

Organize warehouse inventory with flexible categorization systems. Tag materials by type, supplier, or usage to quickly locate items and streamline warehouse operations. Efficient filtering helps locate inventory instantly.

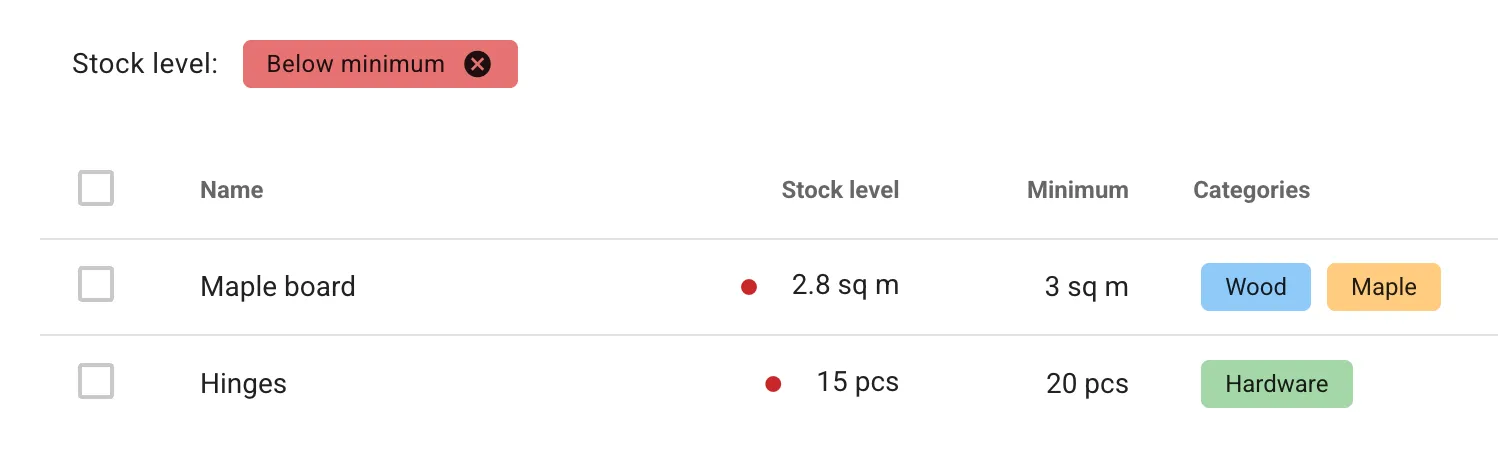

Automated Reorder Alerts

Prevent stockouts with intelligent low-stock notifications. Set minimum levels for critical materials and receive alerts when inventory needs replenishing, ensuring continuous production without warehouse delays.

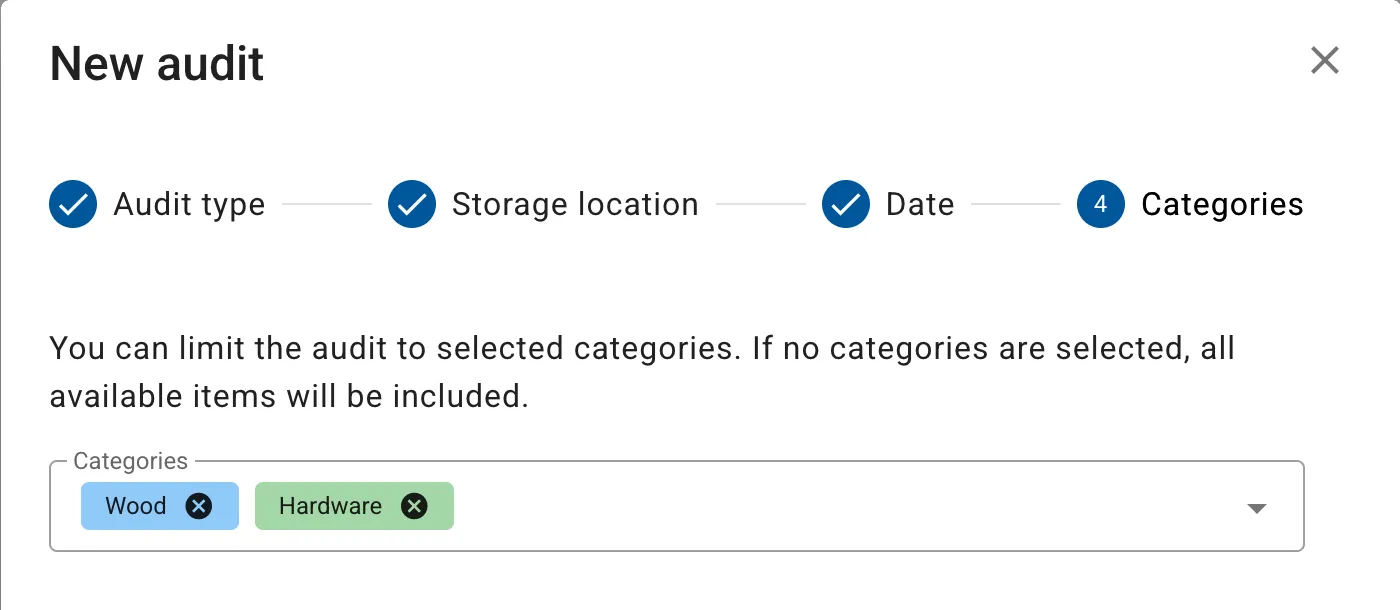

Comprehensive Warehouse Audits

Conduct efficient inventory audits across all warehouse locations. Perform full or partial stock counts, track variances, and maintain accurate records with detailed audit reports highlighting discrepancies.

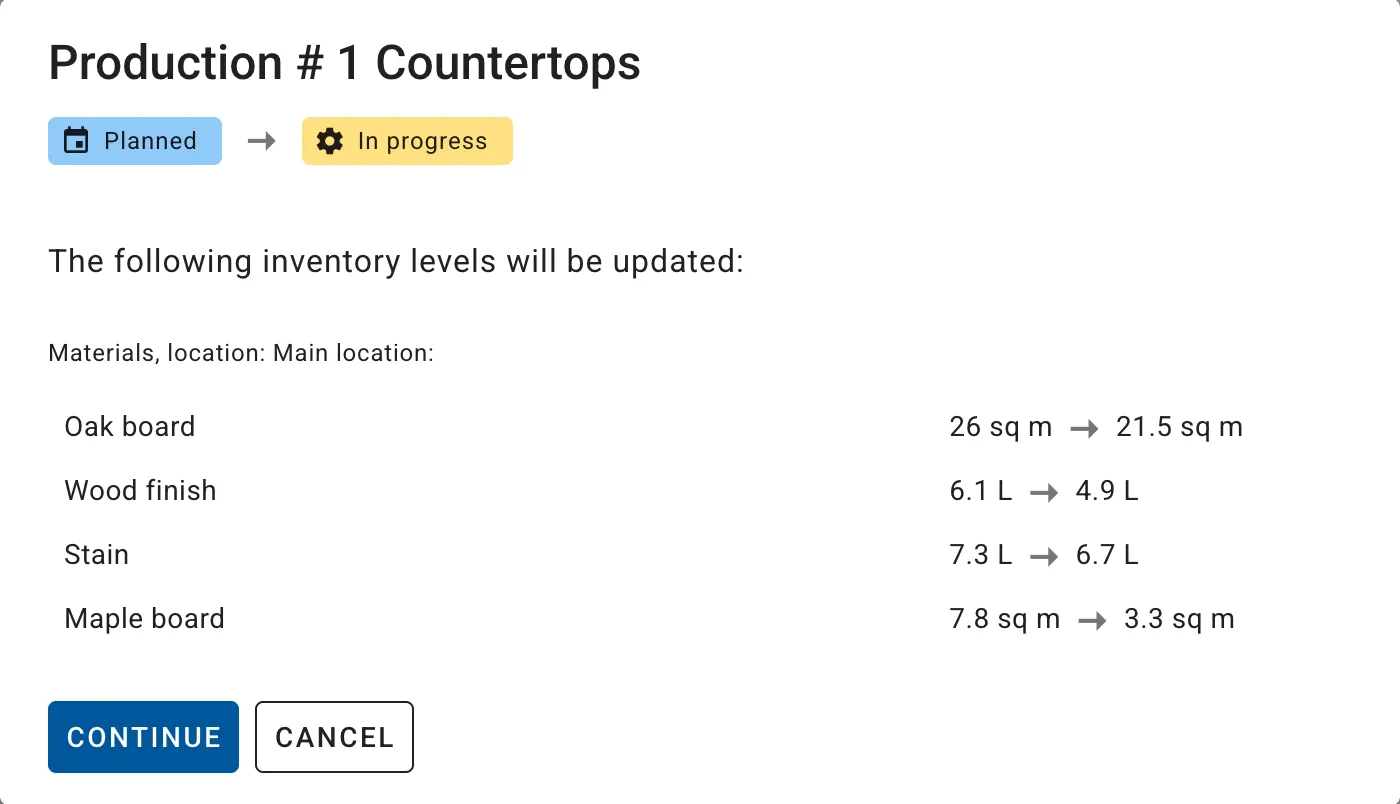

Production-Integrated Operations

Connect warehouse operations directly to production planning. Automatically reserve materials for manufacturing runs, track consumption, and update inventory levels as products move through your production process.

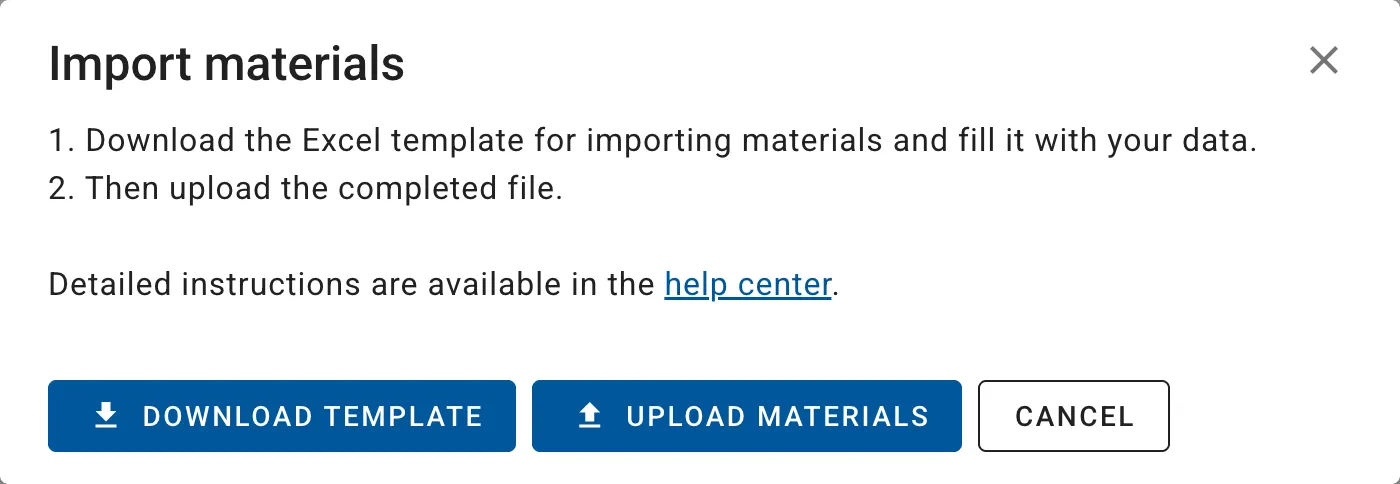

Flexible Data Management

Import existing inventory data effortlessly and export reports for analysis. Migrate from spreadsheets or other systems with bulk import capabilities, ensuring smooth transition to organized warehouse management.

Transform Your Warehouse Operations

Our warehouse inventory systems deliver practical improvements for manufacturing operations:

Multi-Location Control

Gain visibility across all warehouse locations with centralized inventory management. Track stock movements between facilities and maintain consistent processes across your entire warehouse network.

Real-time Warehouse Visibility

Access accurate inventory data instantly from anywhere. Make informed decisions with up-to-the-minute stock levels and movement tracking across all warehouse locations and storage areas.

Improved Inventory Accuracy

Maintain precise stock records with automated updates and regular audit capabilities. Reduce discrepancies and ensure your warehouse data matches physical inventory levels.

Seamless Production Integration

Connect warehouse operations with manufacturing processes. Automatically update inventory as materials are consumed in production and finished goods are completed, eliminating manual data entry.

Faster Stock Management

Streamline warehouse tasks with intuitive interfaces and bulk operations. Update stock levels quickly, process transfers efficiently, and reduce time spent on manual inventory management.

Cost-Effective Solution

Get professional warehouse management capabilities without enterprise complexity or cost. Our WMS system for small business provides essential features at an affordable price point.

Frequently Asked Questions

Can't find the answer to your question? Contact us at [email protected] or use the chat in the bottom-right corner, and we'll respond promptly.